Toyota Corolla (2004+). Manual — part 51

05-671

DIAGNOSTICS

- POWER DOOR LOCK CONTROL SYSTEM

057TE-01

CUSTOMER PROBLEM ANALYSIS CHECK

POWER DOOR LOCK CONTROL SYSTEM Check Sheet

Inspector’s name:

Registration No.

Customer’s Name

Registration Year

Frame No.

Date Vehicle

km

/

/

Odometer Reading

Brought in

Mile

Date Problem First Occurred

/

/

F Constant F Sometimes ( Times per day, month)

Frequency Problem Occurs

F Once only

F Fine

F Cloudy

F Rainy

F Snowy

Weather

Weather Conditions

F Various/Others

When Problem

F Hot F Warm

F Cool

Occurred

Outdoor temperature

F Cold (Approx.

F (

C))

F Malfunction in Door

F Driver’s side door lock

F Driver’s side door

Lock/Unlock Operation

control switch.

F Passenger’s side door

Using Door Lock Control

Switch.

F Passenger’s side door

F Driver’s side door

lock control switch.

F Passenger’s side door

F Malfunction in Door

F Driver’s side door key

F Driver’s side door

Lock/Unlock Operation

lock and unlock control

F Passenger’s side door

Using Key.

switch.

F Passenger’s side door

F Driver’s side door

key lock and unlock control

F Passenger’s side door

switch.

F 2-step unlocking function of driver’s side door key lock

and unlock switch.

F Malfunction in Key Confinement Prevention Function.

F Others.

05-672

DIAGNOSTICS

- POWER DOOR LOCK CONTROL SYSTEM

057TF-01

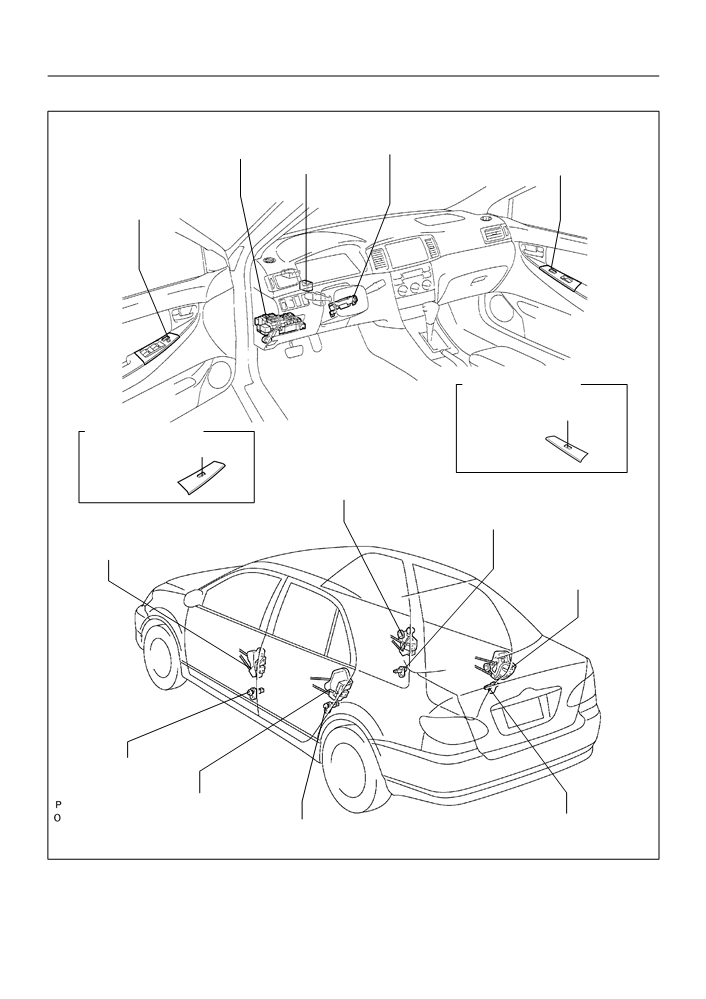

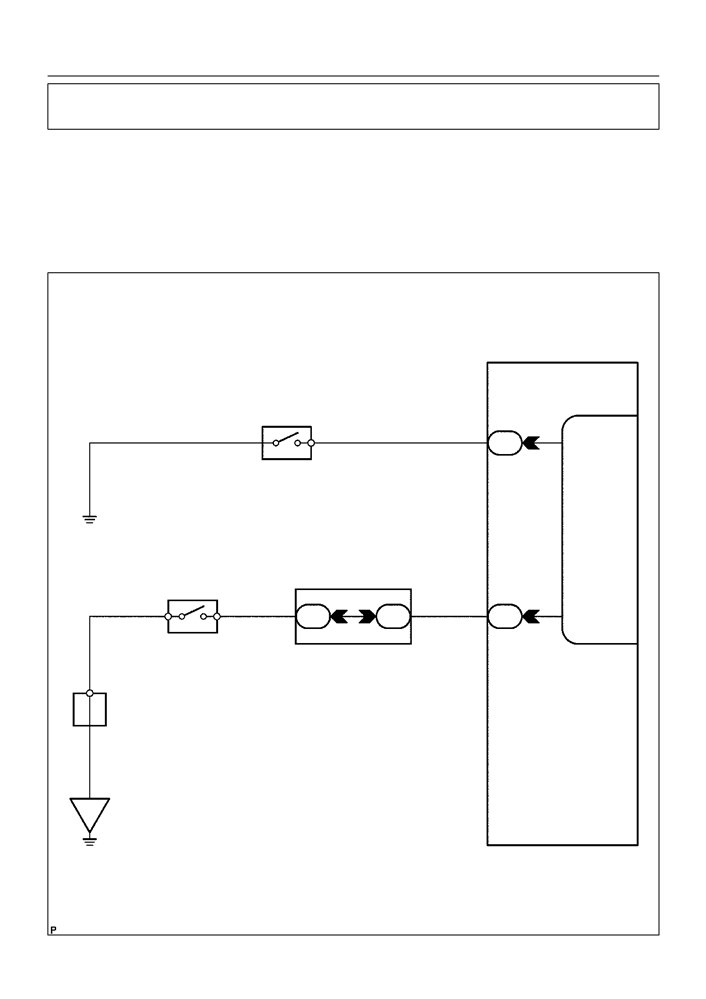

LOCATION

Un-lock Warning

Instrument Panel J/B

Switch Assy

(Integration Relay)

w/ Power Window:

w/ Power Window:

Center J/B

Door Lock Control Switch

Power Window Regulator

Master Switch Assy

(Door Lock Control Switch)

w/o Power Window

Door Lock Control Switch Assy

(Passenger’s Side)

w/o Power Window

Door Lock Control Switch Assy

(Driver’s Side)

Front Door Lock Assy RH

Front Door Courtesy

Lamp Switch Assy

Front Door Lock Assy LH

Rear Door Lock Assy RH

Front Door Courtesy

Lamp Switch Assy

Rear Door Lock Assy LH

Rear Door Courtesy

Rear Door Courtesy

B59155

B59883

Lamp Switch Assy

Lamp Switch Assy

B59152

B59531

05-676

DIAGNOSTICS

- POWER DOOR LOCK CONTROL SYSTEM

057TH-01

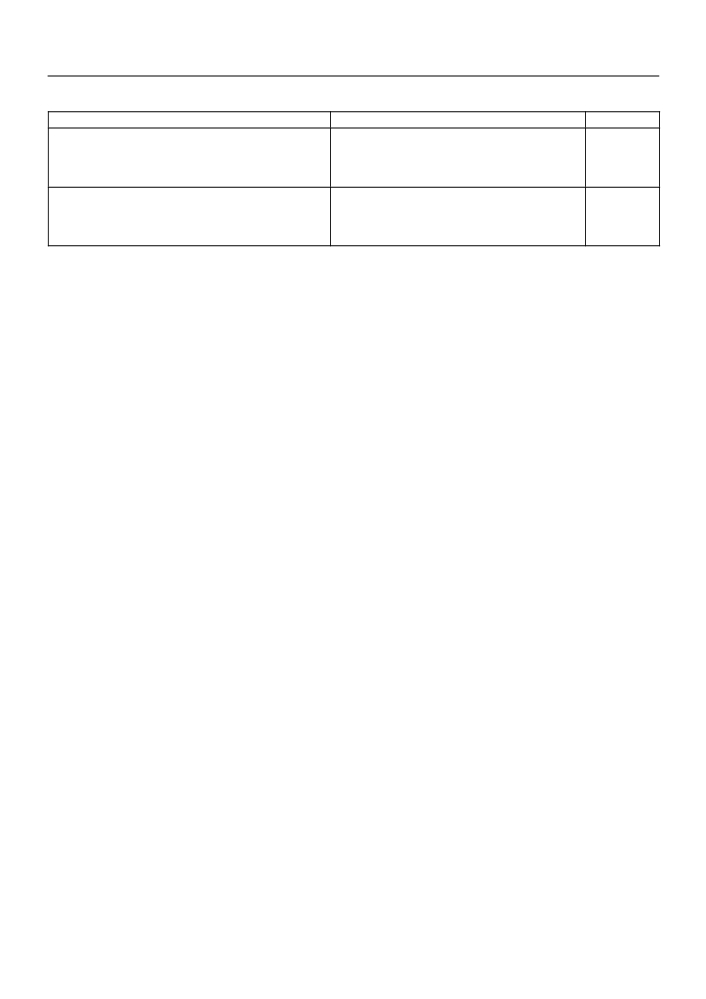

PROBLEM SYMPTOMS TABLE

Symptom

Suspected Area

See page

1. Door lock control switch

All doors are not operated by driver’s door key cylinder

2. Front door lock assy LH

05-677

interlocked with key

3. Wire harness

4. Integration relay

1. Un-lock warning switch assy

Key confinement prevention function does not work properly

2. Front door courtesy lamp switch assy

05-682

(Unlock warning switch circuit)

3. Wire harness

4. Integration relay

05-673

DIAGNOSTICS

- POWER DOOR LOCK CONTROL SYSTEM

057TG-01

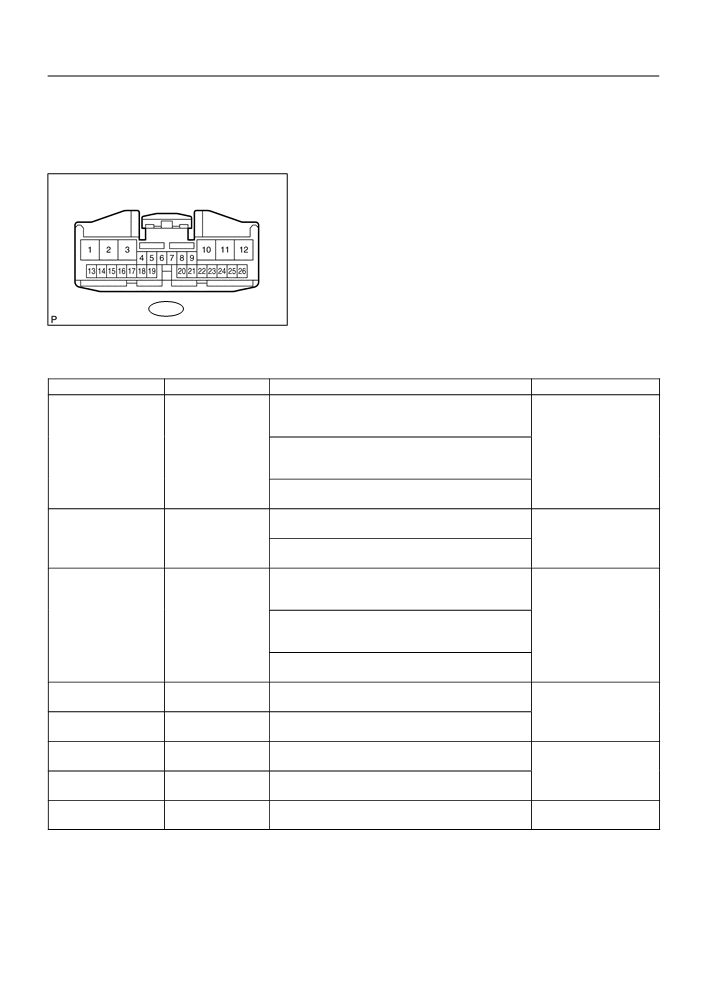

TERMINALS OF ECU

1.

INSPECT INTEGRATION RELAY

Integration Relay Connector

(Wire Harness Side)

I11

B57790

(a) Disconnect the connector and check the continuity of each terminal of the disconnected connector.

Standard :

Symbols (Terminal No.)

Wiring color

Condition

Specified Condition

[w/ power window]

Master switch (Manual door lock operation)

OFF LOCK

L1 (I11-9)

[w/o power window]

L-W Body ground

No continuity Continuity

Body ground

Driver’s door control switch (Manual operation)

OFF LOCK

Passenger’s door control switch (Manual operation)

OFF LOCK

Key in driver’s door lock cylinder

L2 (I11-7)

LOCK Other position

G Body ground

Continuity No continuity

Body ground

Key in passenger’s door lock cylinder

LOCK Other position

[w/ power window]

Master switch (Manual door lock operation)

OFF UNLOCK

UL1 (I11-8)

[w/o power window]

L Body ground

No continuity Continuity

Body ground

Door control switch (Manual operation)

OFF UNLOCK

Passenger’s door control switch (Manual operation)

OFF UNLOCK

UL2 (I11-5)

Key in passenger’s door lock cylinder

L-B Body ground

Body ground

UNLOCK Other position

Continuity No continuity

UL3 (I11-6)

Key in driver’s door lock cylinder

L-Y Body ground

Body ground

UNLOCK Other position

LSWD (I11-19)

Driver’s door lock control knob

W Body ground

Body ground

LOCK UNLOCK

No continuity Continuity

LSWP (I11-18)

Passenger’s door lock control knob

W-R Body ground

Body ground

LOCK UNLOCK

PCTY (I11-13)

R-W Body ground

Passenger’s door fully closed Opened

No continuity Continuity

Body ground

If the result is not as specified, the vehicle’s side may malfunction.

05-674

DIAGNOSTICS

- POWER DOOR LOCK CONTROL SYSTEM

(b) Reconnect the connector and check each terminal.

Standard:

Symbols (Terminal No.)

Wiring color

Condition

Specified Condition

ACTD (I11-1)

Key in driver’s door lock cylinder

0 V 10 - 14 V

R Body ground

Body ground

OFF LOCK

1 V or less

If the result is not as specified, the integration relay may malfunction.

2.

INSPECT INSTRUMENT PANEL J/B (INTEGRATION RELAY)

Instrument Panel J/B (Integration Relay)

Instrument Panel J/B Side

ID

IK

Connector IA

IA

IB

Instrument Panel J/B Side

Connector IB

IF

IH

IJ

Instrument Panel J/B Side

Instrument Panel J/B Side

Instrument Panel J/B Side

Connector IK

Connector IF

Connector IJ

Instrument Panel J/B Side

Instrument Panel J/B Side

Connector IH

Connector ID

B59376

B59378

B59532

05-675

-

DIAGNOSTICS

POWER DOOR LOCK CONTROL SYSTEM

(a) Inspect the DOOR fuse.

(b) Disconnect connectors ID, IF, IH and IJ of the instrument panel J/B.

(c)

Check each terminal of the disconnected connectors.

Standard:

Symbols (Terminal No.)

Wiring color

Condition

Specified Condition

KSW (IJ-8)

L-B Body ground

No key in ignition switch lock cylinder Inserted

No continuity Continuity

Body ground

GND (IF-4)

W-B Body ground

Body ground

Constant

Continuity

GND (IH-10)

W-B Body ground

Body ground

DCTY (ID-1)

R-W Body ground

Driver’s door fully closed Opened

Body ground

PRCTY (ID-14)

R-B Body ground

Rear LH door fully closed Opened

No continuity Continuity

Body ground

PRCTY (ID-15)

R-Y Body ground

Rear RH door fully closed Opened

Body ground

If the result is not as specified, the vehicle’s side may malfunction.

(d) Reconnect the connectors and check each terminal.

Standard:

Symbols (Terminal No.)

Wiring color

Condition

Specified Condition

IG (IA-1) Body ground

W Body ground

Constant

10

- 14 V

+B (IB-1) Body ground

W Body ground

KSW (IJ-8)

L-B Body ground

No key in ignition switch lock cylinder Inserted

10 - 14 V 0 V

Body ground

ACT+ (IK-2)

Key in driver’s door lock cylinder

L Body ground

Body ground

OFF LOCK

ACT+ (ID-9)

Key in driver’s door lock cylinder

L Body ground

Body ground

OFF UNLOCK

0 V 10 - 14 V

ACT- (IK-5)

Key in driver’s door lock cylinder

1 V or less

R Body ground

Body ground

OFF LOCK

ACT- (ID-20)

Key in driver’s door lock cylinder

R Body ground

Body ground

OFF UNLOCK

If the result is not as specified, the instrument panel J/B (integration relay) assembly may malfunction.

05-670

DIAGNOSTICS

- POWER DOOR LOCK CONTROL SYSTEM

POWER DOOR LOCK CONTROL SYSTEM

057TD-01

HOW TO PROCEED WITH TROUBLESHOOTING

1

VEHICLE BROUGHT IN

2

CUSTOMER PROBLEM ANALYSIS CHECK AND SYMPTOM CHECK

(See page 05-671)

3

PROBLEM SYMPTOMS TABLE (See page 05-676)

(a) Without applicable symptoms, proceed to ”A”

(b) With applicable symptoms, proceed to ”B”

B

GO TO STEP 5

A

4

PERFORM TROUBLESHOOTING IN THE FOLLOWING METHOD, DEPENDING ON

MALFUNCTION SYMPTOM

(a) Terminals of ECU (See page 05-673)

(b) Inspection (See page 73-3)

(c)

On-vehicle inspection (See page 73-1)

5

ADJUSTMENT, REPAIR OR REPLACEMENT

END

05-682

DIAGNOSTICS

- POWER DOOR LOCK CONTROL SYSTEM

057TJ-01

KEY CONFINEMENT PREVENTION FUNCTION DOES NOT WORK

PROPERLY (UNLOCK WARNING SWITCH CIRCUIT)

CIRCUIT DESCRIPTION

The unlock warning switch turns on when the key is inserted in the ignition key cylinder and the door courtesy

switch turns on when the driver’s door is opened, and the integration relay monitors both switches conditions.

According to these switches conditions, the integration relay controls the door locking operation not to lock

the doors while both switches are on, in order to prevent the key from being confined.

WIRING DIAGRAM

Instrument Panel J/B

D4

I11

Front Door Courtesy Lamp Switch Assy

Integration Relay

(Driver’s Side)

1

1

R-W

5

ID

DCTY

U1

Center J/B

Un-lock Warning Switch Assy

15

16

8

W-B

1

2

L-B

L-B

4

*1

4A

4A

IJ

KSW

A

J6

J/C

*1: w/ Door Lock Control

IE

B59535

05-683

DIAGNOSTICS

- POWER DOOR LOCK CONTROL SYSTEM

INSPECTION PROCEDURE

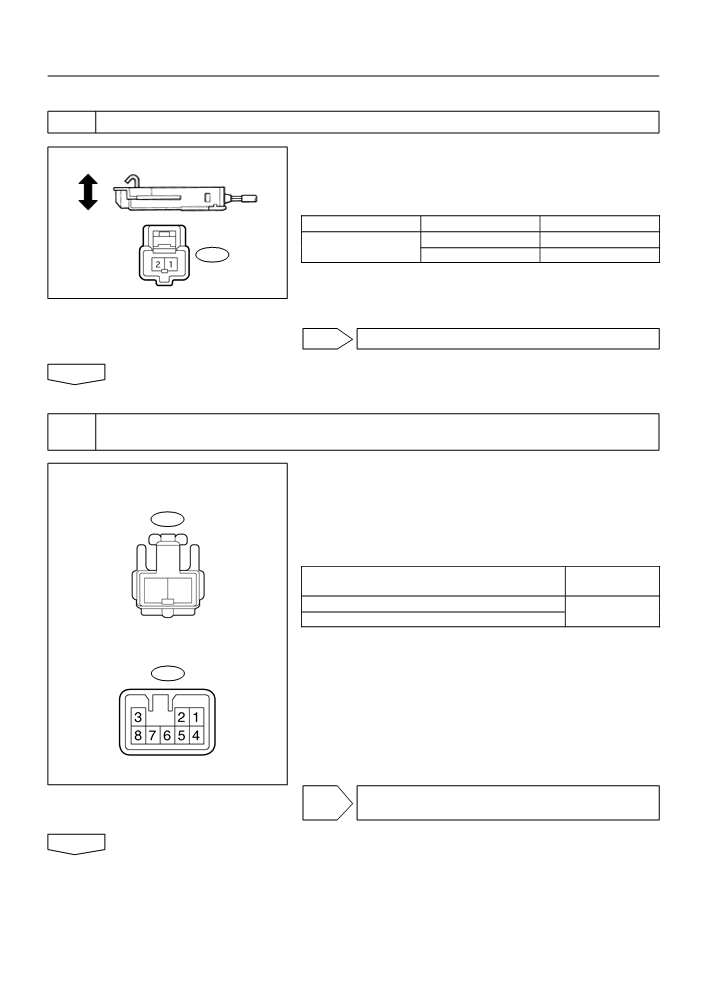

1

INSPECT UN-LOCK WARNING SWITCH ASSY

(a) Remove the un-lock warning switch assy.

Free Un-lock Warning Switch Assy

(b) Inspect the un-lock warning switch assy continuity, as

shown in the illustration and table.

Standard:

Push

Terminal No.

Condition

Specified condition

Free

No continuity

U1-1 U1-2

U1

Push

Continuity

B51903

NG REPLACE UN-LOCK WARNING SWITCH ASSY

OK

2

CHECK WIRE HARNESS

(UN-LOCK WARNING SWITCH INSTRUMENT PANEL J/B)

(a) Disconnect the un-lock warning switch assy and instru-

Un-lock Warning Switch Assy

ment panel J/B connectors.

(Wire Harness Side)

(b) Check the continuity between the terminals of the un-lock

U1

warning switch assy and instrument panel J/B connec-

tors, as shown in the illustration and table.

Standard (Check for open):

Symbols (Terminal No.)

Specified condition

1

2

(Un-lock warning switch Instrument panel J/B)

(U1-2) KSW (IJ-8)

Continuity

(U1-1) Body ground

Instrument Panel J/B

(Wire Harness Side)

IJ

B59536

NG REPAIR OR REPLACE WIRE HARNESS AND

CONNECTOR

OK

05-684

DIAGNOSTICS

- POWER DOOR LOCK CONTROL SYSTEM

3

INSPECT FRONT DOOR COURTESY LAMP SWITCH ASSY (DRIVER’S SIDE)

Front Door Courtesy Lamp Switch Assy

(a) Remove the courtesy lamp switch.

(Driver’s Side)

(b) Inspect the courtesy lamp switch continuity, as shown in

Free

D4

the illustration and table.

Push

Standard:

Terminal No.

Condition

Specified condition

Free

Continuity

D4-1 Body ground

Push

No continuity

B58556

NG REPLACE FRONT DOOR COURTESY LAMP

SWITCH ASSY

OK

4

CHECK WIRE HARNESS

(FRONT DOOR COURTESY LAMP SWITCH ASSY [DRIVER’S SIDE]

INSTRUMENT PANEL J/B)

(a) Disconnect the courtesy lamp switch and instrument pan-

Front Door Courtesy Lamp Switch Assy

el J/B connectors.

[Driver’s Side] (Wire Harness Side)

(b) Check the continuity between the terminals of the courte-

D4

sy lamp switch and instrument panel J/B connectors, as

shown in the illustration and table.

Standard (Check for open):

Symbols (Terminal No.)

1

Specified condition

(Courtesy lamp switch Instrument panel J/B)

(D4-1) DCTY (ID-1)

Continuity

Instrument Panel J/B

(Wire Harness Side)

ID

NG REPAIR OR REPLACE WIRE HARNESS AND

B59537

CONNECTOR

OK

REPLACE INTEGRATION RELAY

05-41

DIAGNOSTICS

- SFI SYSTEM (April, 2003)

05CRM-02

CHECK FOR INTERMITTENT PROBLEMS

Hand-held tester only:

By putting the vehicle’s ECM in the check mode, the 1 trip detection logic is possible instead of the

2 trip detection logic, and the sensitivity to detect faults is increased. This makes it easier to detect

intermittent problems.

(a) Clear the DTCs (See page 05-11).

(b) Set the check mode (See page 05-11).

(c)

Perform a simulation test (See page 01-20).

(d) Check the connector and terminal (See page 01-30).

(e) Wiggle the harness and connector (See page 01-30).

05-11

DIAGNOSTICS

- SFI SYSTEM (April, 2003)

05CRI-02

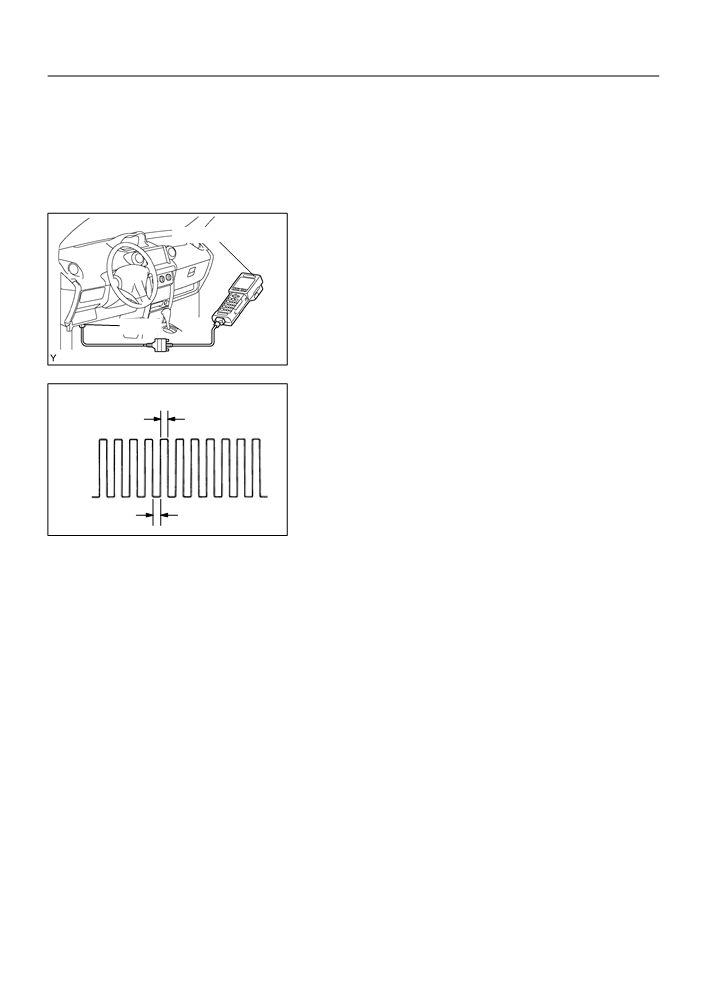

CHECK MODE PROCEDURE

HINT:

Hand-held tester only:

Compared to the normal mode, the check mode has more sens-

ing ability to detect malfunctions. Furthermore, the same diag-

nostic items which are detected in the normal mode can also be

detected in the check mode.

1.

CHECK MODE PROCEDURE(Using the hand-held

Hand-held Tester

tester)

(a) Check the initial conditions.

(1)

Battery positive voltage 11 V or more

(2)

Throttle valve fully closed

(3)

Transmission in the P or N position

(4)

A/C switched OFF

DLC3

(b) Turn the ignition switch OFF.

A79121

(c)

Connect the hand-held tester to the DLC3.

(d) Turn the ignition switch ON.

(e) Switch the hand-held tester from the normal mode to the

check mode (check that the MIL flashes).

0.13 sec.

NOTICE:

ON

If the hand-held tester switches the ECM from the normal

mode to the check mode or vice-versa, or if the ignition

switch is turned from ON to ACC or OFF during the check

OFF

mode, the DTC and freeze frame data will be erased.

(f)

Start the engine (MIL goes off after the engine starts).

0.13 sec.

A76900

(g) Simulate the conditions of the malfunction described by

the customer.

NOTICE:

Leave the ignition switch ON until you have checked the

DTC, etc.

(h) After simulating the malfunction conditions, check the

DTC and freeze frame data, etc using the hand-held tes-

ter diagnosis selector.

HINT:

Do not turn the ignition switch OFF, as turning it OFF switches

the diagnosis system from the check mode to the normal mode,

which erases all the DTCs, etc.

(i)

After checking the DTC, inspect the applicable circuit.

2.

CLEAR DTC (Using the OBD II scan tool or hand-held

tester)

(a) Connect the OBD II scan tool or hand-held tester to the

DLC3.

(b) Turn the ignition switch ON.

(c)

Operate the OBD II scan tool or hand-held tester to erase

the codes. All the DTCs and freeze frame data will be

erased. (See the OBD II scan tool’s manual book for

operating manuals.)

05-12

DIAGNOSTICS

- SFI SYSTEM (April, 2003)

3.

CLEAR DTC (Not using the OBD II scan tool or hand-

held tester)

(a) Disconnect the battery terminal or remove the EFI fuse

from the engine room R/B for more than 60 seconds.

05-27

DIAGNOSTICS

- SFI SYSTEM (April, 2003)

05DIG-01

CHECKING MONITOR STATUS

HINT:

”MONITOR RESULT” indicates normal or malfunction of each

component and system when judgment has done.

1.

HOW TO READ DATA

MONITOR RESULT

(a) Connect the hand-held tester to the DLC 3.

CATALYST#1 B1 . INCMP

(b) Enter ”MONITOR RESULT” from ”DIAGNOSIS / EN-

CATALYST#1 B2 . INCMP

O2S HEAT B1S1 . INCMP

HANCED OBD II / MONITOR INFO / MONITOR RESULT”

O2S HEAT B1S2 . INCMP

on the hand-held tester. You will see ”Test ID” and

O2S HEAT B2S1 . INCMP

”INCMP”, ”Pass” or ”Fail” on the MONITOR RESULT

O2S HEAT B2S2 . INCMP

THERMOSTAT

PASS

screen.

Press [ENTER] to

HINT:

Select the Label .

A82674

F

INCMP: The judgement has not been done yet.

F

PASS: Normal is detected.

F

FAIL: Malfunction is detected.

(c)

Select a Test ID that you want from the list and press the

Thermostat malfunction

”ENTER” button. You will see the following screen:

VAL

119.375_C

(1)

VAL (TEST VALUE)

[Test Data] [Unit]

LMT

75.000_C

(2)

LMT (TEST LIMIT)

[Test Limit] [Unit]

TLT

1

(3)

TLT

[Test Limit Type]

[HELP] to notice

[EXIT] to return

A82675

(d) By pressing the ”HELP” button, you can see more in-

When TEST is PASS,

formation.

TLT =

0

VALUE < LIMIT

HINT:

TLT =

1

VALUE > LIMIT

F

Monitor test results can be viewed in the MONITOR RE-

SULT screen.

When TEST is FAIL,

TLT =

0

F

Monitor test results indicate the latest malfunction judge-

VALUE > LIMIT

TLT =

1

ment result of this diagnostic.

VALUE < LIMIT

F

TEST VALUE indicates the detection parameter value

[EXIT] to return

A82676

(Example: P0128 Thermostat Malfunction = Engine cool-

ant temperature) at the time of malfunction (or normal)

judgement is done.

F

TEST LIMIT indicates a threshold of malfunction judge-

ment (Example: P0128 Thermostat Malfunction = 75_C).

F

When the monitor runs, the monitored Parameter’s VAL-

UE is recorded. The value is then compared to the TEST

LIMIT to determine if the result is PASS or FAIL.

F

By comparing the Parameter VALUE to the TEST LIMIT,

it is possible to determine the degree of failure.

05-28

DIAGNOSTICS

- SFI SYSTEM (April, 2003)

F

In rare cases, the monitor may have passed even with a

DTC set and MIL illuminated. The monitor may have

failed on a previous trip, and then passed on the most re-

cent trip. This would indicated an intermittent problem

may be the cause of the DTC.

Большое спасибо!

Ваше мнение очень важно для нас.

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст