Lexus ES300 (2002 year). Service manual — part 206

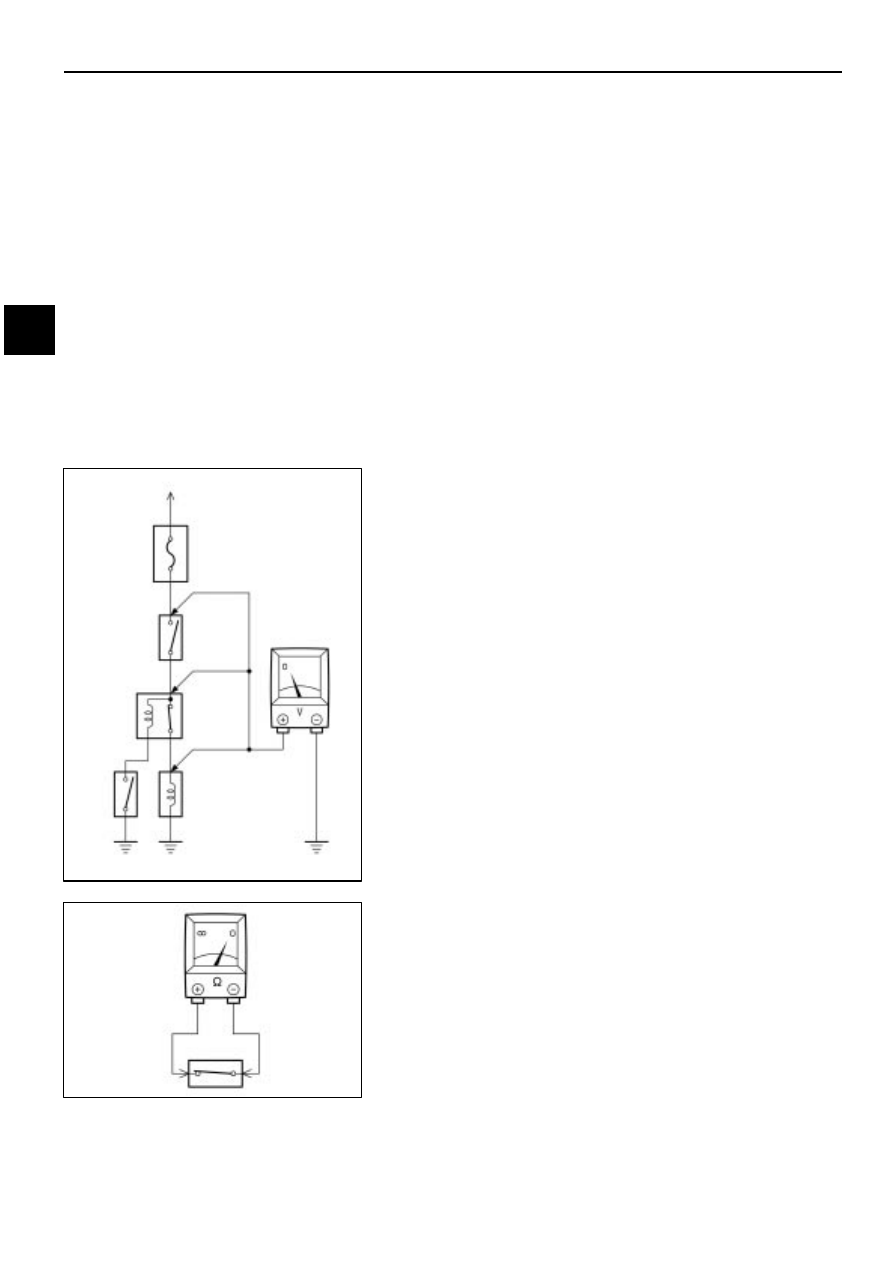

To Ignition SW

IG Terminal

Fuse

Relay

SW2

Solenoid

Voltmeter

[A]

[B]

[C]

SW1

Ohmmeter

SW

INTRODUCTION–HOW TO PERFORM FOR SYSTEM INSPECTION

A–5

6

Wire Harness Repair Manual (RM1022E)

HOW TO PERFORM FOR SYSTEM INSPECTION

This inspection procedure is a simple troubleshooting which should be carried out on the vehicle during

system operation and is based on the assumption of system component trouble

Always inspect the trouble taking the following items into consideration:

Ground point fault

Open or short circuit of the wire harness

Connector or terminal connection fault

Fuse or fusible link fault

NOTICE:

This is an on–vehicle inspection during system operation.

Therefore, inspect the trouble with due regard for safety.

If connecting the battery directly, be careful not to cause a short circuit, and select the applicable

voltage.

1.

Voltage Check

(a)

Establish conditions in which voltage is present at the

check point.

Example:

[A] – Ignition SW on

[B] – Ignition SW and SW 1 on

[C] – Ignition SW, SW 1 and Relay on (SW 2 off)

(b)

Using a voltmeter, connect the negative (–) lead to a

good ground point or negative (–) battery terminal

and the positive (+) lead to the connector or

component terminal. This check can be done with a

test bulb instead of a voltmeter.

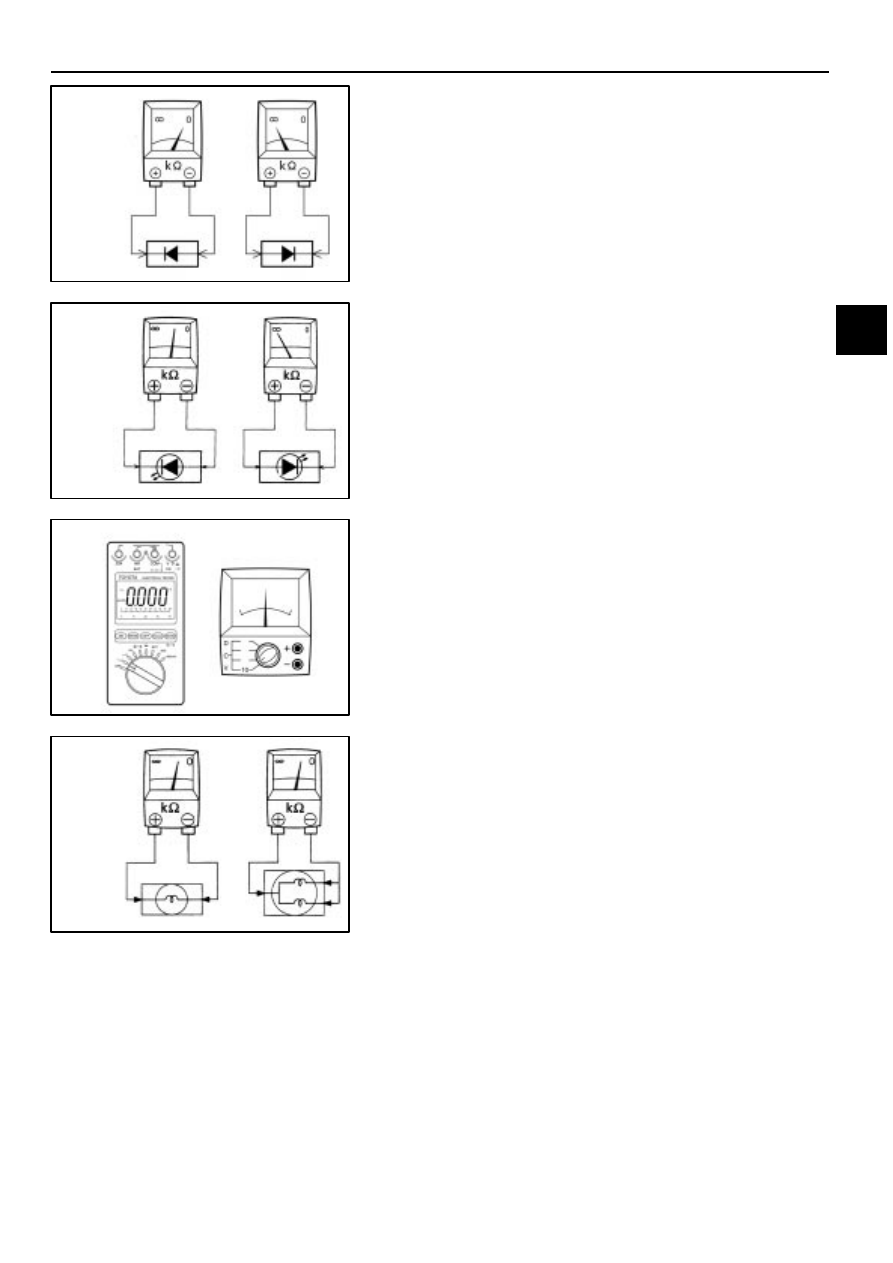

2.

Continuity and Resistance Check

(a)

Disconnect the battery terminal or wire so there is no

voltage between the check points.

(b)

Contact the two leads of an ohmmeter to each of the

check points.

A

Diode

Ohmmeter

Diode

Ohmmeter

Digital Type

Analog Type

Bulb

Ohmmeter

A–6

INTRODUCTION–HOW TO PERFORM FOR SYSTEM INSPECTION

7

Wire Harness Repair Manual (RM1022E)

If the circuit has diodes, reverse the two leads and check

again.

When touching the negative (–) lead to the diode positive

(+) side and the positive (+) lead to the negative (–) side,

there should be continuity. When touching the two leads in

reverse, there should be no continuity.

HINT:

Specifications may vary depending on the type of

tester, so refer to the tester’s instruction manual before

performing the inspection.

Check LED (Light Emitting Diode) in the same manner as

that for diodes.

HINT:

Use a tester with a power source of 3V or greater to

overcome the circuit resistance.

If a suitable tester is not available, apply battery

voltage and check that the LED lights up.

(c)

Use a volt/ohmmeter with high impedance (10k

Ω

/V

minimum) for troubleshooting of the electrical circuit.

3.

Bulb Check

(a)

Remove the bulb.

(b)

There should be continuity between the respective

terminals of the bulb together with a certain amount

of resistance.

(c)

Apply the two leads of the ohmmeter to each of the

terminals.

(d)

Apply battery voltage and check that the bulb light up.

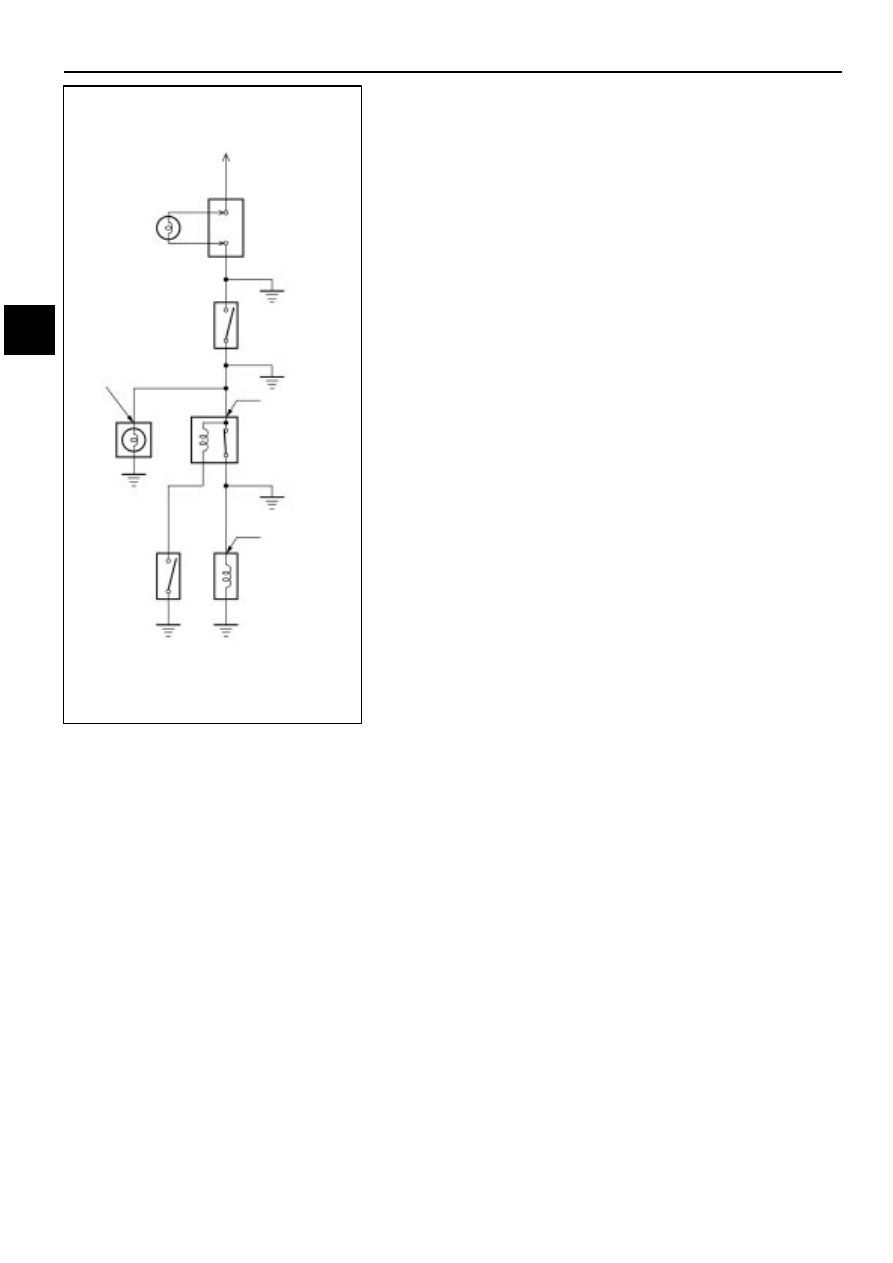

A

Fuse Case

Test Bulb

Short [A]

SW1

Short [B]

Relay

Light

Short [C]

SW2

Solenoid

Disconnect

Disconnect

Disconnect

To Ignition SW

IG Terminal

INTRODUCTION–HOW TO PERFORM FOR SYSTEM INSPECTION

A–7

8

Wire Harness Repair Manual (RM1022E)

4.

Finding a Short Circuit

(a)

Remove the blown fuse and eliminate all loads from

the fuse.

(b)

Connect a test bulb in place of the fuse.

(c)

Establish conditions in which the test bulb comes on.

Example:

[A] – Ignition SW on

[B] – Ignition SW and SW 1 on

[C] – Ignition SW, SW 1 and Relay on (Connect the Relay)

and SW 2 off (or disconnect SW 2)

(d)

Disconnect and reconnect the connectors while

watching the test bulb. The short lies between the

connector where the test bulb stays lit and the

connector where the bulb goes out.

(e)

Find the exact location of the short by lightly shaking

the problem wire along the body.

CAUTION:

(a)

Do not open the cover or the case of the ECU

unless absolutely necessary. (If the IC terminals

are touched, the IC may be destroyed by static

electricity.)

(b)

When replacing the internal mechanism (ECU

part) of the digital meter, be careful that no part of

your body or clothing comes in contact with the

terminals of leads from the IC, etc. of the

replacement part (spare part).

A

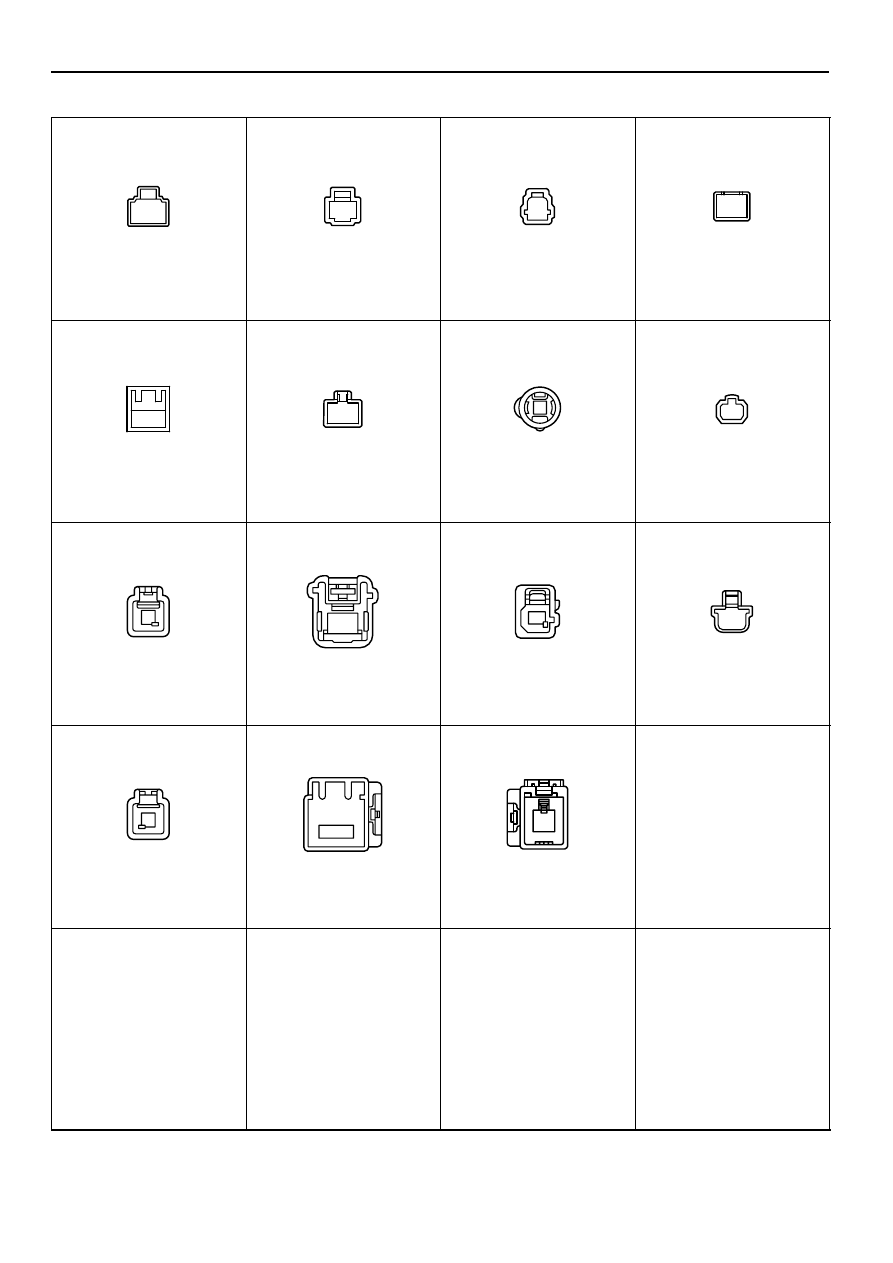

D–200

TABLE OF HOUSING SHAPE

Wire Harness Repair Manual (RM1022E)

275

<MALE> 1P Non–waterproof Type

1

1

1

1

90980–10160

90980–10178

90980–10182

90980–10251

1

1

1

1

90980–10433

90980–10253

90980–10342

90980–10396

90980–10434

1

90980–10870

90980–11026

1

1

1

90980–11097

90980–10994

90980–11146

90980–11258

1

1

1

90980–11737

90980–11774

90980–12041

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст