Lexus ES300 (2002 year). Service manual — part 134

ENGINE – 1MZ-FE ENGINE

EG-27

206EG19

206EG18

Yoke

Armature

Brush

Armature

Surface

Commutator

Permanent Magnet

Brush

Length

STARTING SYSTEM

Starter

1) General

A compact and lightweight PS (Planetary reduction-Segment conductor motor) starter has been

adopted on all models.

Because the PS starter contains an armature that uses square-shaped conductors, and its surface func-

tions as a commutator, it has resulted in both improving its output torque and reducing its overall

length.

In place of the field coil used in the conventional starter, the PS starter uses two types of permanent

magnets: main magnets and interpolar magnets. The main magnets and interpolar magnets have been

efficiently arranged to increase the magnetic flux and to shorten the length of the yoke.

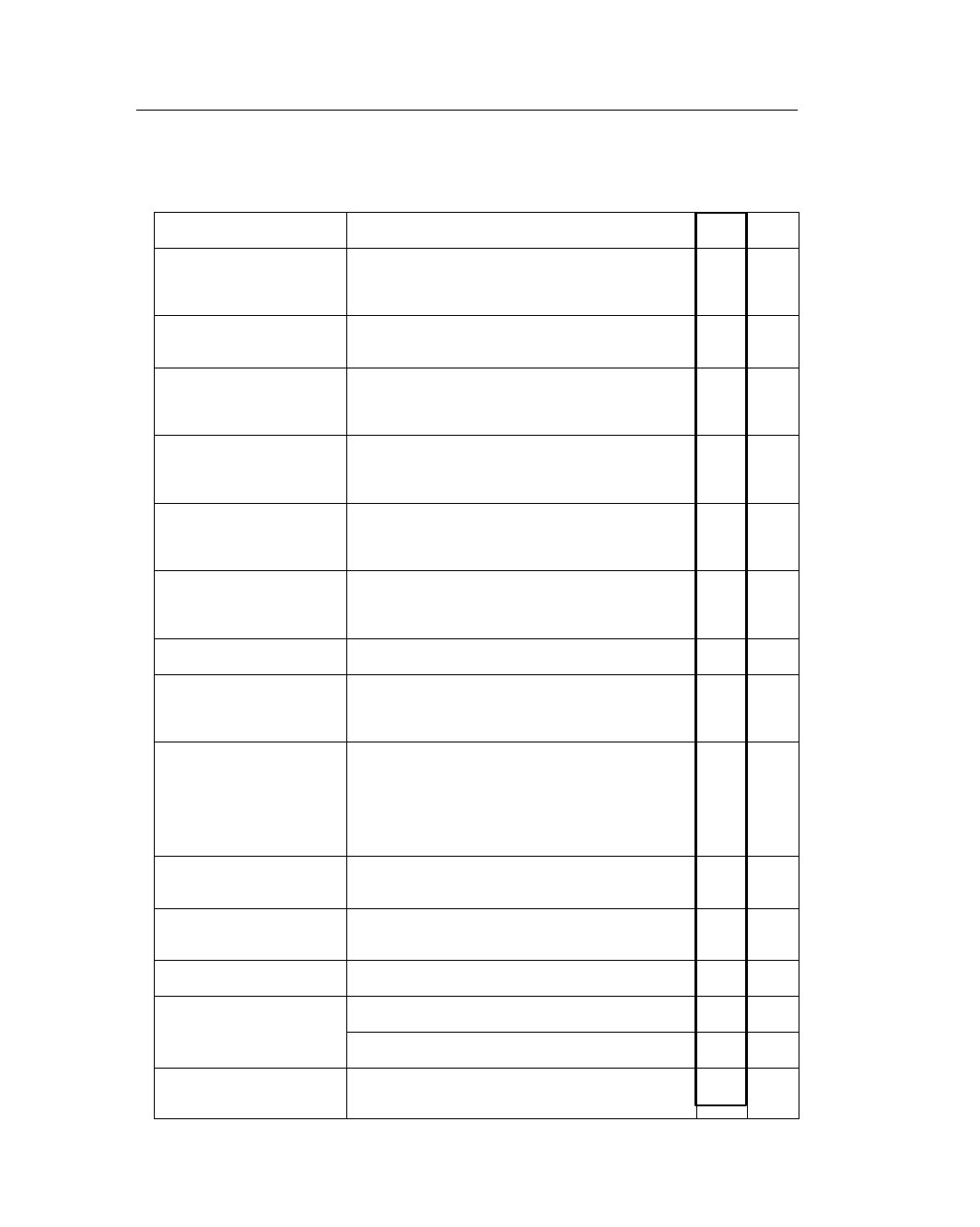

Specifications

Model

PS Starter

Conventional Type Starter

Length

128 mm (5.04 in.)

145 mm (5.71 in.)

Weight

2950 g

3800 g

Rating Voltage

12 V

12 V

Rating Output

1.6 kW

1.4 kW

Rotating of Direction

Counterclockwise*

*: Viewed from Pinion Side

ENGINE – 1MZ-FE ENGINE

EG-28

206EG20

Conventional Type Starter

PS Starter

Armature

A

A

B

B

Armature

Brush

Commutator

Brush

Surface

Commutator

Square-Shaped

Conductor

Round-Shaped

Conductor Wire

A – A Cross Section

PS Starter

B – B Cross Section

Conventional Type

206EG21

Cross Section of Yoke

Main Magnets

Yoke

Interpolar Magnets

Magnetic Flux Generated

by Main Magnets

Magnetic Flux Generated by

Relationship Between Main

Magnets

Armature

2) Construction

Instead of the construction of the armature coil of the conventional starter that uses round-shaped con-

ductor wires, the PS starter uses square conductors. With this type of construction, the same conditions

that are realized by winding numerous round-shaped conductor wires can be achieved without increas-

ing the mass. As a result, the output torque has been increased, and the armature coil has been made

more compact.

Because the surface of the square-shaped conductors that are used in the armature coil functions as

a commutator, the overall length of the PS starter has been shortened.

Instead of the field coils used in the conventional starter, the PS starter has adopted two types of perma-

nent magnets: the main magnets and the interpolar magnets. The main and interpolar magnets are ar-

ranged alternately inside the yoke, allowing the magnetic flux that is generated between the main and

interpolar magnets to be added to the magnetic flux that is generated by the main magnets.

In addition to increasing the amount of magnetic flux, this construction shortens the overall length of

the yoke.

ENGINE – 1MZ-FE ENGINE

EG-29

211EG11

Torque Rod

Right Mount

(Hydraulic

Engine Mount)

Active Control

Engine Mount

Left Mount

(Hydraulic

Engine Mount)

211EG31

Intake Air Chamber

Vacuum

Tank

Engine

VSV

ECM

Active Control

Engine Mount

Side Branch

Main Liquid

Chamber

Diaphragm

Air

Chamber

Rubber

161ES46

ENGINE MOUNT

1. General

A 3-point support on the front subframe has been

adopted. An active control engine mount has been

adopted on the front engine mount and a hydraulic

engine mount has been adopted on the right and

left engine mounts to realize low noise and vibra-

tion and to achieve high levels of both riding com-

fort and drivability.

2. Active Control Engine Mount

The operating range of the active control engine mount is during idling under the engine speeds of 900 rpm.

Signals that are synchronized to the engine rpm are sent by the ECM to the VSV and the engine vacuum is

utilized to vary the pressure of the intake air chamber in the active control engine mount. As a result, the dia-

phragm vibrates, and using the liquid as a medium, the rubber mount vibrates.

This vibration of the engine mount acts to cancel out the engine vibration during idle, thus reducing the vibra-

tion and noise at idle.

The engine mount’s damping force to generate vibrations is adjusted through the effects of the orifice and

the side branch.

ENGINE – 1MZ-FE ENGINE

EG-30

ENGINE CONTROL SYSTEM

1. General

The engine control system of the 1MZ-FE engine has following system.

System

Outline

’02

ES300

’01

ES300

SFI

(Sequential Multiport

Fuel Injection)

(For details, see page EG-38)

An L-type SFI system directly detects the intake air

mass with a hot wire type mass air flow meter.

ESA

(Electronic Spark Advance)

(For details, see page EG-38)

Ignition timing is determined by the ECM based on

signals from various sensors. The ECM corrects

ignition timing in response to engine knocking.

ETCS-i

(Electronic Throttle

Control System-intelligent)

(For details, see page EG-39)

Optimally controls the throttle valve opening in

accordance with the amount of accelerator pedal effort

and the condition of the engine and the vehicle.

—

VVT-i

(Variable Valve

Timing-intelligent)

(For details, see page EG-41)

Controls the intake camshaft to an optimal valve timing

in accordance with the engine condition.

ACIS

(Acoustic Control

Induction System)

(For details, see page EG-42)

The intake air passages are switched according to the

engine speed and throttle valve opening angle to provide

high performance in all speed ranges.

Air Intake Control

System

(For details, see page EG-46)

The intake air duct is divided into two areas, and the

ECM controls the air intake control valve and the

actuator that are provided in one of the areas to reduce

the amount of engine noise.

—

Fuel Pump Control

Fuel pump operation is controlled by signal from the

ECM.

Air Fuel Ratio Sensor,

Oxygen Sensor

Heater Control

Maintains the temperature of the air fuel ratio sensor or

oxygen sensor at an appropriate level to increase

accuracy of detection of the oxygen concentration in the

exhaust gas.

Evaporative

Emission Control

(For details, see page EG-47)

The ECM controls the purge flow of evaporative

emission (HC) in the charcoal canister in accordance

with engine conditions.

Using 3 VSVs and a vapor pressure sensor, the ECM

detects any evaporative emission leakage occurring

between the fuel tank and the charcoal canister

through the changes in the tank pressure.

Active Control Engine

Mount

(For details, see page EG-29)

The damping characteristic of the front engine mount is

controlled variably to reduce idling vibration.

Air Conditioning

Cut-off Control

By turning the air conditioner compressor ON or OFF

in accordance with the engine condition, drivability is

maintained.

Engine Immobiliser

Prohibits fuel delivery and ignition if an attempt is made

to start the engine with an invalid ignition key.

Diagnosis

When the ECM detects a malfunction, the ECM

diagnoses and memorizes the failed section.

Diagnosis

(For details, see page EG-52)

To increase the speed for processing the signals, the

32-bit CPU of the ECM has been adopted.

—

Fail-Safe

(For details, see page EG-53)

When the ECM detects a malfunction, the ECM stops or

controls the engine according to the data already stored

in the memory.

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст