Lexus ES300 (2002 year). Service manual — part 120

CHASSIS – U150E AUTOMATIC TRANSAXLE

CH-9

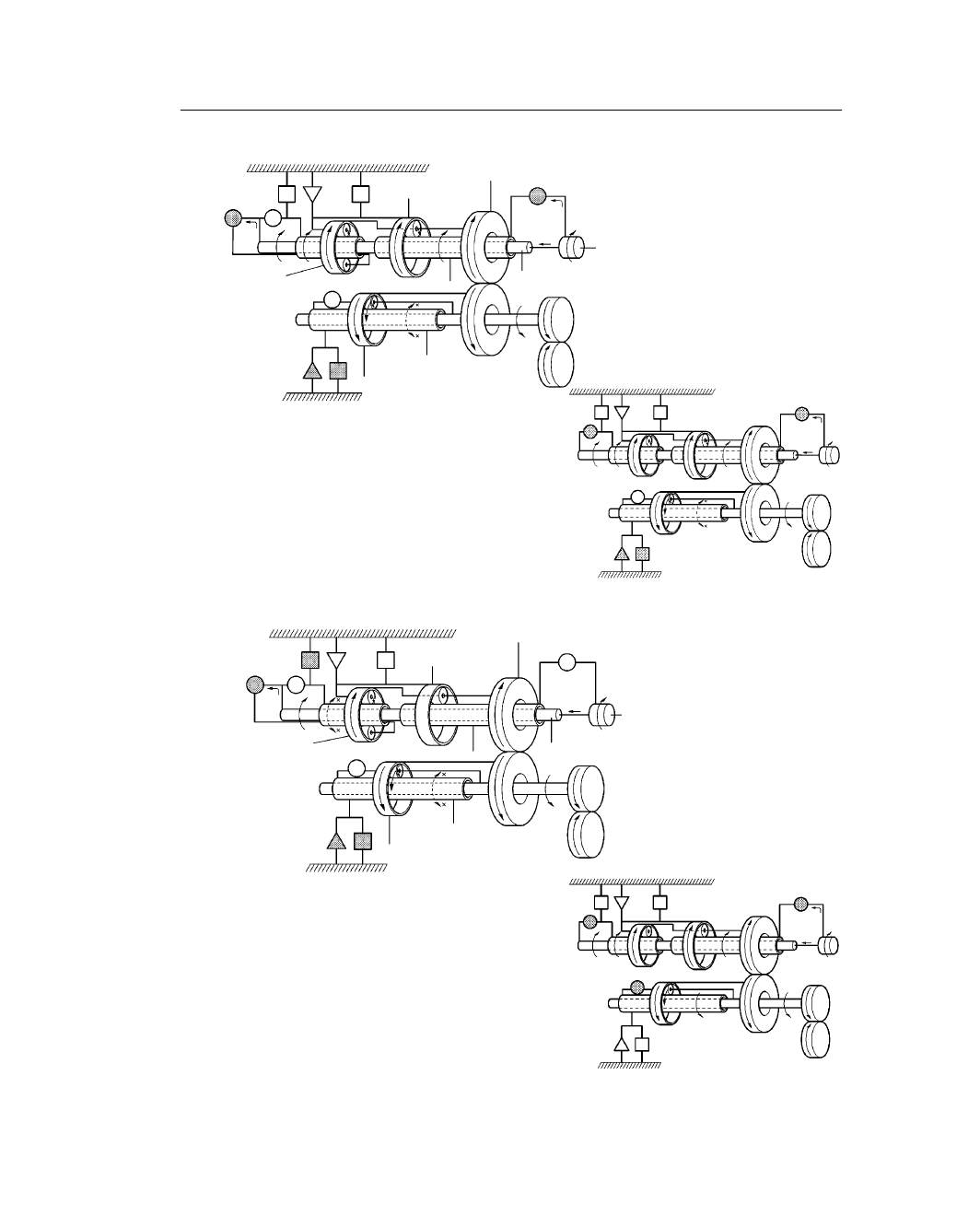

211CH06

U150E

U140E

Counter Drive Gear

Front Planetary Gear

Input Shaft

Rear Planetary Gear

Sun Gear

Intermediate Shaft

Differential Drive

Pinion

Sun Gear

U / D Planetary Gear

Ring Gear

B

1

F

1

B

2

C

0

C

2

C

1

C

3

F

2

B

3

211CH58

U150E

U140E

Counter Drive Gear

Front Planetary Gear

Input Shaft

Rear Planetary Gear

Sun Gear

Intermediate Shaft

Differential Drive

Pinion

Sun Gear

U / D Planetary Gear

Ring Gear

B

1

F

1

B

2

C

0

C

2

C

1

C

3

F

2

B

3

211CH07

211CH59

3rd Gear

4th Gear

CHASSIS – U150E AUTOMATIC TRANSAXLE

CH-10

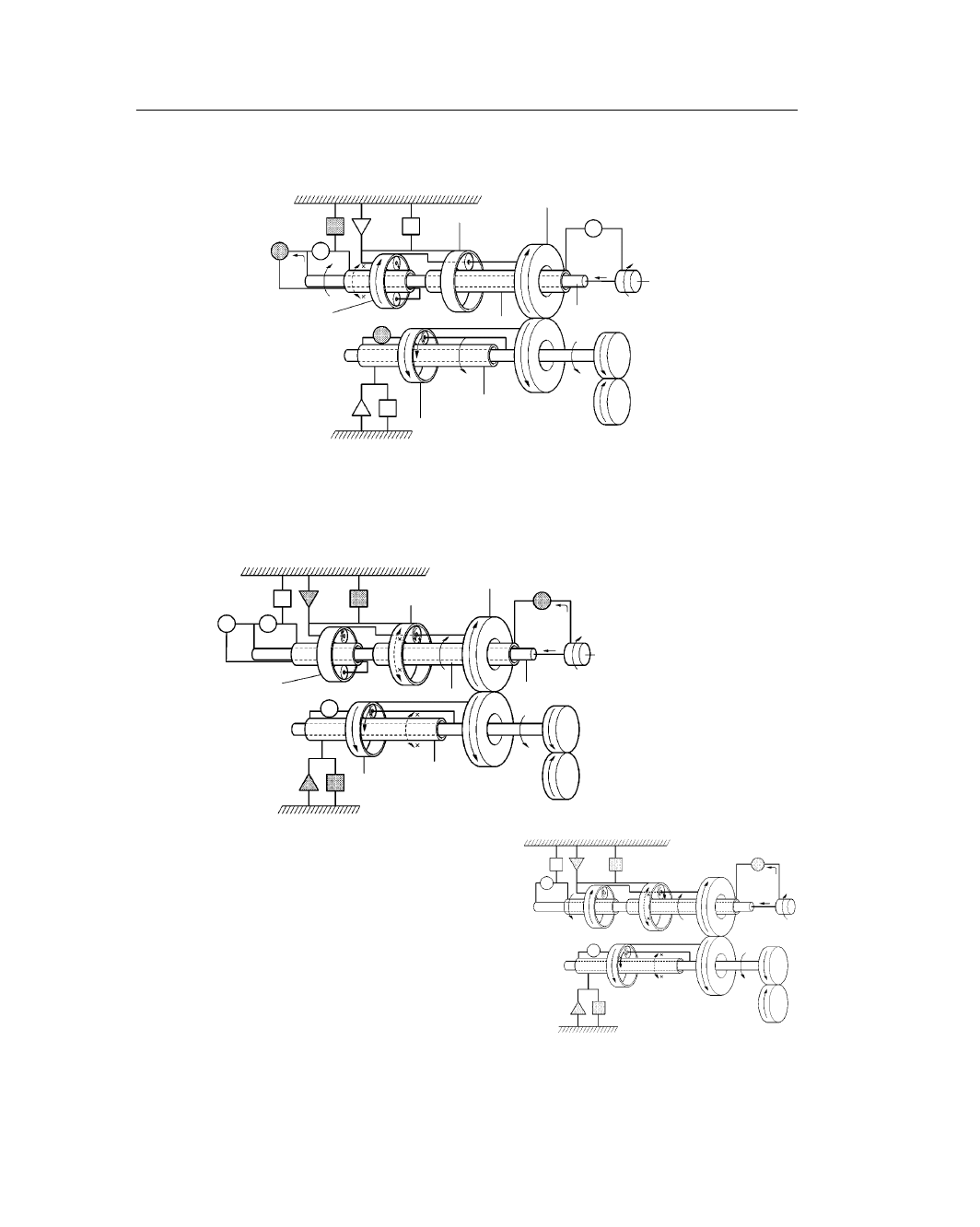

211CH08

Counter Drive Gear

Front Planetary Gear

Input Shaft

Rear Planetary Gear

Sun Gear

Intermediate Shaft

Differential Drive

Pinion

Sun Gear

U / D Planetary Gear

Ring Gear

B

1

F

1

B

2

C

0

C

2

C

1

C

3

F

2

B

3

161ES13

U150E

U140E

Counter Drive Gear

Front Planetary Gear

Input Shaft

Rear Planetary Gear

Sun Gear

Intermediate Shaft

Differential Drive

Pinion

Sun Gear

U / D Planetary Gear

Ring Gear

B

1

F

1

B

2

C

0

C

2

C

1

C

3

F

2

B

3

211CH09

5th Gear

1st Gear (L Position)

CHASSIS – U150E AUTOMATIC TRANSAXLE

CH-11

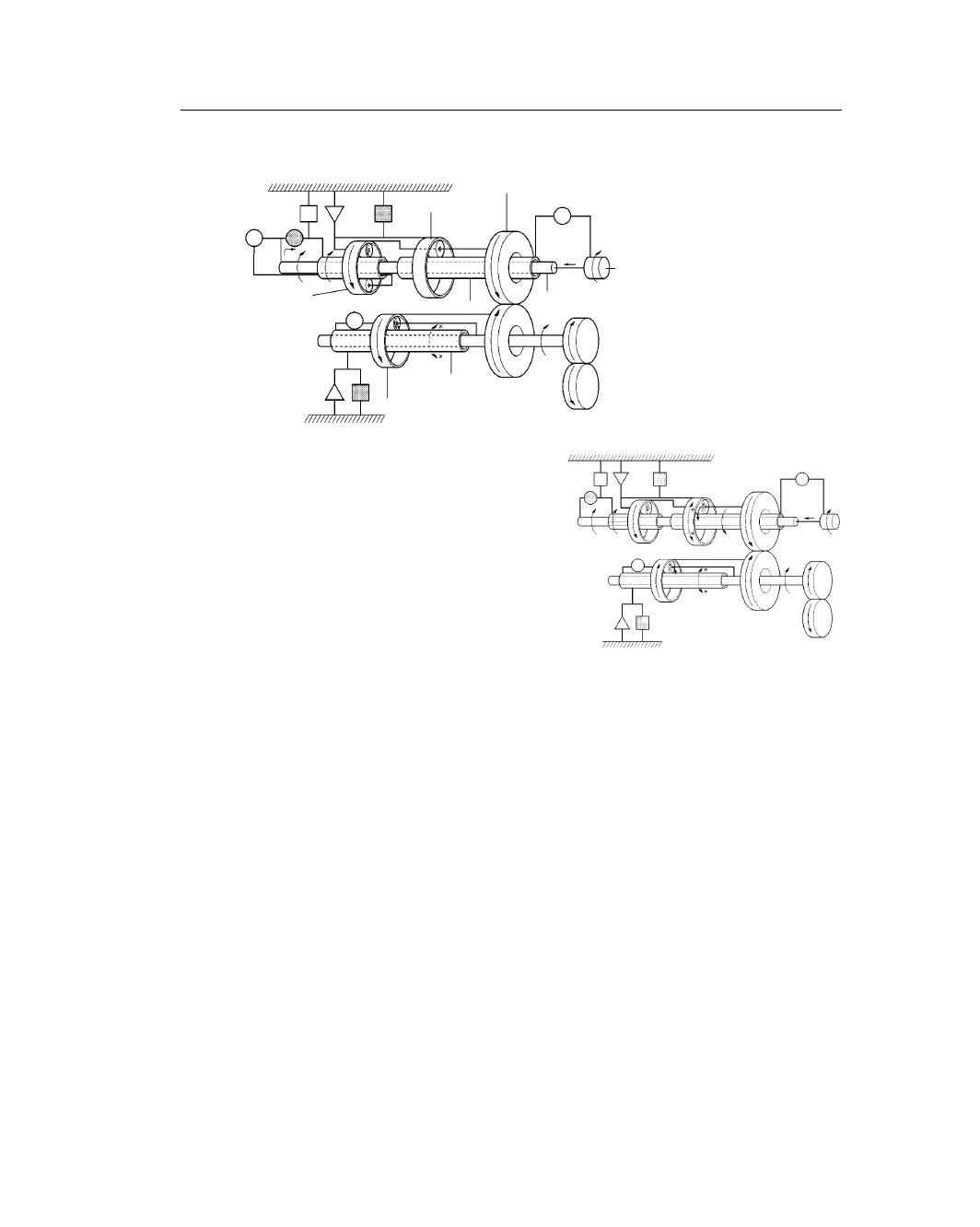

211CH10

U150E

U140E

Front Planetary Gear

Counter Drive Gear

Input Shaft

Rear Planetary Gear

Sun Gear

Intermediate Shaft

Differential Drive

Pinion

Sun Gear

U / D Planetary Gear

Ring Gear

B

1

F

1

B

2

C

0

C

2

C

1

C

3

F

2

B

3

181CH66

Reverse Gear (R Position)

CHASSIS – U150E AUTOMATIC TRANSAXLE

CH-12

211CH11

C

0

Clutch

Piston

Chamber A

Chamber B

C

0

Clutch

C

2

Clutch

C

1

Clutch

C

3

Clutch

157CH17

Fluid pressure

applied to piston

Centrifugal fluid pressure

applied to chamber B

Target fluid pressure

(original clutch pressure)

—

=

Target Fluid Pressure

Centrifugal Fluid Pressure

Applied to the Chamber A

Clutch

Centrifugal Fluid Pressure

Applied to Chamber B

Chamber B

(Lubrication Fluid)

Piston Fluid

Pressure

Chamber

Fluid Pressure

Applied to Piston

Shaft Side

4. Centrifugal Fluid Pressure Canceling Mechanism

There are two reasons for improving the conventional clutch mechanism:

To prevent the generation of pressure by the centrifugal force that applied to the fluid in piston fluid

pressure chamber (hereafter referred to as “chamber A”) when the clutch is released, a check ball is

provided to discharge the fluid. Therefore, before the clutch can be subsequently applied, it took time for

the fluid to fill the chamber A.

During shifting, in addition to the original clutch pressure that is controlled by the valve body, the pressure

that acts on the fluid in the chamber A also exerts influence, which is dependent upon revolution fluctua-

tions.

To address these two needs for improvement, a canceling fluid pressure chamber (hereafter referred to as

“chamber B”) has been provided opposite chamber A.

By utilizing the lubrication fluid such as that of the shaft, the same amount of centrifugal force is applied,

thus canceling the centrifugal force that is applied to the piston itself. Accordingly, it is not necessary to

discharge the fluid through the use of a check ball, and a highly responsive and smooth shifting characteristic

has been achieved.

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст