Lexus ES300 (2002 year). Service manual — part 140

2002

All rights reserved. This book may not be

reproduced or copied, in whole or in part, without the

written permission of Toyota Motor Corporation.

FOREWORD

This manual has been prepared for use when

performing terminal repairs, wire repairs, or connector

repairs on vehicles.

A step–by–step section on connector repair and

terminal repair is included.

There is a section of charts with terminal and connector

illustrations, part numbers, and notes on terminal

removal.

By using this guide, a satisfactory repair of the wiring

harness and connectors in Toyota vehicles will be easy

to achieve.

All information in this manual is based on the latest

product information at the time of publication. However,

specifications and procedures are subject to change

without notice.

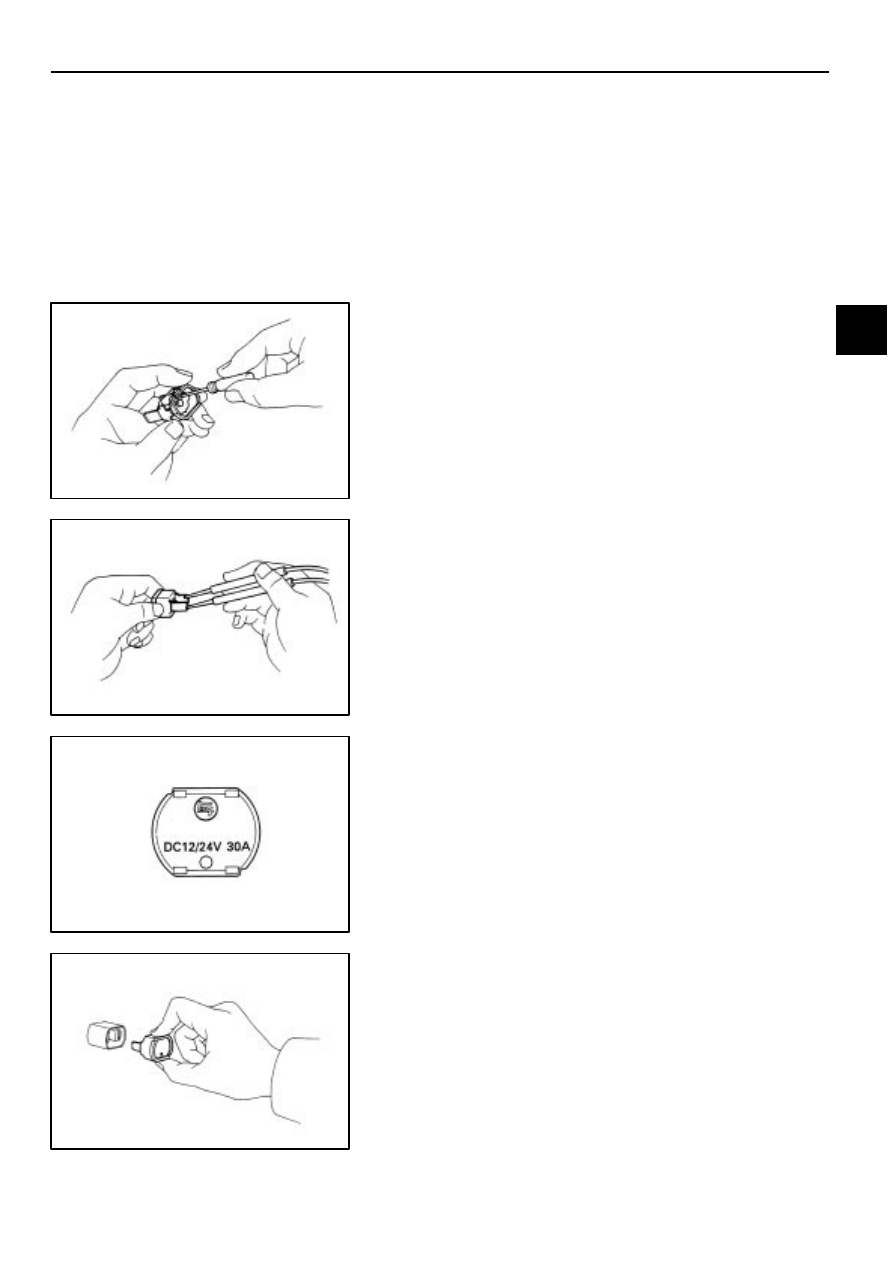

Push

Equal Amperage Rating

A–8

INTRODUCTION–CIRCUIT PROTECTION

9

Wire Harness Repair Manual (RM1022E)

CIRCUIT PROTECTION

All electrical circuits are protected against excessive loads which might occur because of shorts or

overloads in the wiring system. Such protection is provided by a fuse, circuit breaker, or fusible link, A

short circuit may cause a fuse to blow or a circuit breaker to open.

RESET CIRCUIT BREAKER

1.

Remove Circuit Breaker

(a)

Disconnect the negative (–) cable from the battery.

(b)

Remove the circuit breaker.

2.

Reset Circuit Breaker

(a)

Insert the needle into the reset hole and push it.

(b)

Using an ohmmeter, check that there is continuity

between both terminals of the circuit breaker.

If continuity is not as specified, replace the circuit breaker.

HINT:

If replacing the circuit breaker, be sure to replace

it with a breaker with an equal amperage rating.

3.

Install Circuit Breaker

(a)

Install the circuit breaker.

(b)

Connect the negative (–) cable to the battery.

HINT:

If a circuit breaker continues to cut out, a short

circuit is indicated. Have the system checked by a qualified

technician.

A

Equal Amperage Rating

Equal Amperage Rating

Puller

INTRODUCTION–CIRCUIT PROTECTION

A–9

10

Wire Harness Repair Manual (RM1022E)

REPLACEMENT OF FUSE AND FUSIBLE LINK

HINT:

If replacing the fuse or fusible link, be sure to

replace it with a fuse or fusible link with an equal amperage

rating.

NOTICE:

1.

Turn off all electrical components and the ignition

switch before replacing a fuse or fusible link. Do

not exceed the fuse or fusible link amperage rating.

2.

Always use a fuse puller for removing and

inserting a fuse. Remove and insert straight in and

out without twisting. Twisting could force open the

terminals too much, resulting in a bad connection.

If a fuse or fusible link continues to blow, a short circuit is

indicated. The system must be checked by a qualified

technician.

HINT:

The puller is located at Junction Block No.2.

A

TERMINAL AND CONNECTOR REPAIR–CONNECTOR REPAIR

B–2

12

Wire Harness Repair Manual (RM1022E)

CONNECTOR REPAIR

The repair parts now in supply are limited to those connectors having common shapes and terminal

cavity numbers. Therefore, when there is no available replacement connector of the same shape or

terminal cavity number, please use one of the alternative methods described below. Make sure that the

terminals are placed in the original order in the connector cavities, if possible, to aid in future diagnosis.

1. When a connector with a different number of terminals than the original part is used, select a connector

having more terminal cavities than required, and replace both the male and female connector parts.

EXAMPLE:

You need a connector with six terminals, but the only replacement available is a connector

with eight terminal cavities. Replace both the male and female connector parts with the eight terminal part,

transferring the terminals from the old connectors to the new connectors.

2. When several different type terminals are used in one connector, select an appropriate male and female

connector part for each terminal type used, and replace both male and female connector parts.

EXAMPLE:

You need to replace a connector that has two different types of terminals in one connector.

Replace the original connector with two new connectors, one connector for one type of terminal, another

connector for the other type of terminal.

3. When a different shape of connector is used, first select from available parts a connector with the

appropriate number of terminal cavities, and one that uses terminals of the same size as, or larger than,

the terminal size in the vehicle. The wire lead on the replacement terminal must also be the same size as,

or larger than, the nominal size of the wire in the vehicle. (”Nominal” size may be found by looking at the

illustrations in the section F or by direct measurement across the diameter of the insulation). Replace all

existing terminals with the new terminals, then insert the terminals into the new connector.

EXAMPLE:

You need to replace a connector that is round and has six terminal cavities. The only round

replacement connector has three terminal cavities. You would select a replacement connector that has

six or more terminal cavities and is not round, then select terminals that will fit the new connector. Replace

the existing terminals, then insert them into the new connector and join the connector together.

B

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст