Lexus SC300 / Lexus SC400. Service manual — part 599

RECOMMENDED TOOLS

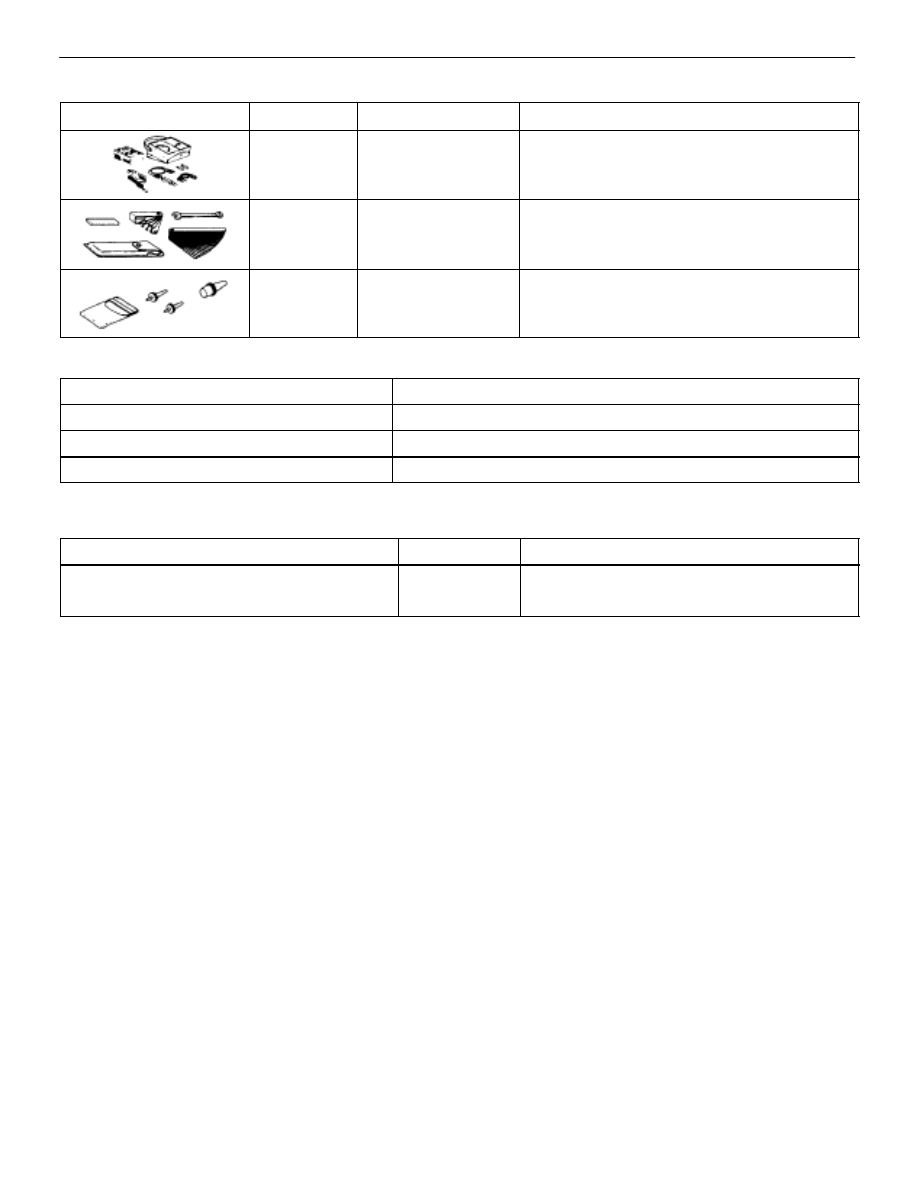

Illustration

Part No.

Part Name

Note

09082–0015

TOYOTA

Electrical Tester

09200–00010

Engine Adjust

Kit

09258–00030

Hose Plug Set

Plug for the Vacuum hose, fuel hose ect.

EQUIPMENT

Part Name

Note

Graduated cylinder

Injector

Tachometer

Torque wrench

SSM (SERVICE SPECIAL MATERIALS)

Part Name

Part No.

Use etc.

Seal packing 1282B,

08826–00100

Water inlet housing

Three bond 1282B or equivalent

FI–11

EFI SYSTEM – Preparation

PRECAUTIONS

1.

Before working on the fuel system, disconnect the cable

from negative (–) terminal of the battery.

HINT: Any diagnostic code retained by the computer will be

erased when the battery terminal is removed. Therefore, if

necessary, read the diagnosis before removing the battery

terminal.

CAUTION: Work must be started after approx. 20 se-

conds or longer from the time the ignition switch is

turned to the ”LOCK” position and negative (–) terminal

cable is disconnected from the battery.

2.

Do not smoke or work on open flame when working on

the fuel system.

3.

Keep gasoline away from rubber or leather parts.

INSPECTION PRECAUTIONS

MAINTENANCE PRECAUTIONS

1.

CHECK CORRECT ENGINE TUNE–UP

(See page

2.

PRECAUTIONS WHEN CONNECTING GAUGE

(a) Use the battery as the power source for the timing light,

tachometer, etc.

(b) Connect the test probe of a tachometer to the terminal

IG of the check connector.

3. IN EVENT OF ENGINE MISFIRE, FOLLOWING

PRECAUTIONS SHOULD BE TAKEN

(a) Check proper connection of battery terminals, etc.

(b) Handle high–tension cords carefully.

(c) After repair work, check that the ignition coil terminals

and all other ignition system lines are reconnected

securely.

(d) When cleaning the engine compartment, be especially

careful to protect the electrical system from water.

4.

PRECAUTIONS WHEN HANDLING OXYGEN SENSOR

(a) Do not allow oxygen sensor to drop or hit against an

object.

(b) Do not allow the sensor to come into contact with water.

FI–12

– Precautions, Inspection Precautions

EFI SYSTEM

FUEL SYSTEM

Fuel Pump

ON–VEHICLE INSPECTION

1.

CHECK FUEL PUMP OPERATION

(a) Using SST, connect terminals +B and FP of the check

(”DIAGNOSIS”) connector.

SST 09843–18020

(b) Turn the ignition switch ON.

NOTICE: Do not start the engine.

(c) Check that there is pressure in the fuel inlet hose from

the fuel filter.

HINT: At this time, you will hear fuel return noise.

(d) Turn the ignition switch OFF.

(e) Remove SST from the check connector.

SST 09843–18020

FI–17

– Fuel System (Fuel Pump)

EFI SYSTEM

If there is no pressure, check the following parts:

•

Fuses

•

EFI main relay

•

Fuel pump ECU

•

Fuel pump

•

Engine & ECT ECU

•

Wiring connections

2.

CHECK FUEL PRESSURE

(a) Check the battery voltage above 12 volts.

(b) Disconnect the cable from the negative (–) terminal of

the battery.

CAUTION: Work must be started after approx. 20 se-

conds or longer from the time the ignition switch is

turned to the ”LOCK” position and negative (–) terminal

cable is disconnected from the battery.

(c) (Exc. USA Spec.)

Remove the filter from the VSV (for EGR system).

(d) Remove

the union bolt holding the LH deliver pipe to the

rear fuel pipe. Remove the two gaskets.

HINT:

•

Put a suitable container or shop towel under the cold

start injector pipe.

•

Slowly loosen the union bolt.

(e) Install the rear fuel pipe and SST (pressure gauge) to

the LH delivery pipe with three new gaskets and the

union bolt.

SST 09268–45012

Torque: 39 N

⋅

m (400 kgf

⋅

cm, 29 ft

⋅

lbf)

(f) Wipe off any splattered gasoline.

(g) (Exc. USA Spec.)

Reinstall the filter to the VSV.

(h) Using SST, connect terminals B and FP of the check

(”DIAGNOSIS”) connector.

SST 09843–18020

(i)

Reconnect the cable to the negative (–) terminal of the

battery.

FI–18

EFI SYSTEM – Fuel System (Fuel Pump)

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст