Lexus SC300 / Lexus SC400. Service manual — part 536

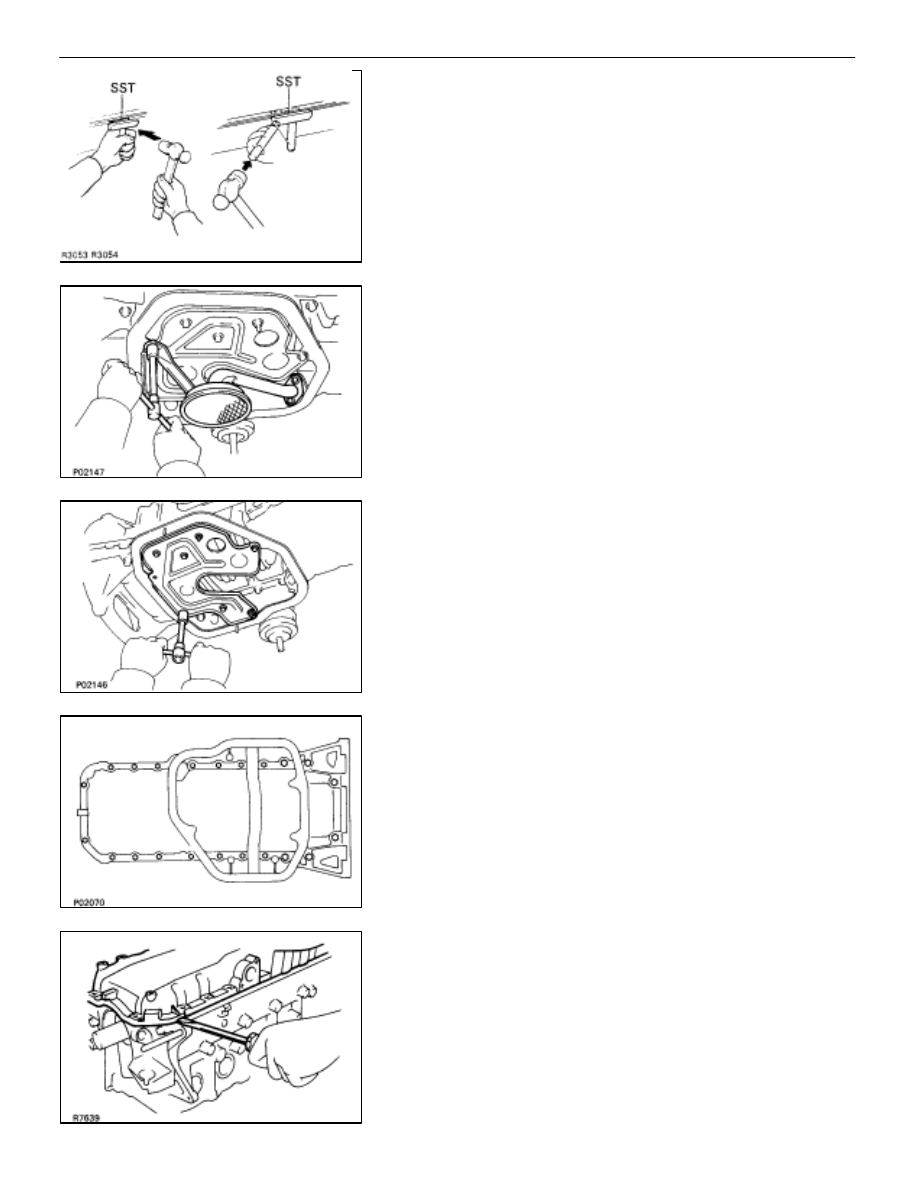

(b) Insert the blade of SST between the No.1 and No.2 oil

pan, break the seal of the applied sealer and remove the

No.1 oil pan.

SST 09032–00100

NOTICE:

•

Be careful not to damage the No.2 oil pan contact surface

of the No.1 oil pan.

•

Be careful not to damage the oil pan flange.

9.

REMOVE OIL STRAINER

Remove the bolt, two nuts, oil strainer and gasket.

10. REMOVE OIL PAN BAFFLE PLATE

Remove the five bolts, two nuts and baffle plate.

11. REMOVE NO.1 OIL PAN

(a) Remove the 22 mounting bolts.

(b) Remove

the No.1 oil pan by prying the portions between

the cylinder block and No.1 oil pan with a screwdriver.

NOTICE: Be careful not to damage the contact surfaces

of the cylinder block and No.1 oil pan.

(c) Remove the O–ring from the cylinder block.

–

LUBRICATION SYSTEM

Oil Pump

LU–11

12. REMOVE OIL PUMP

(a) Remove the nine mounting bolts.

(b) Using a hammer and a brass bar, remove the oil pump

by carefully tapping the oil pump body.

(c) Remove the two O–ring from the cylinder block.

COMPONENTS FOR DISASSEMBLY AND

ASSEMBLY OF OIL PUMP

LU–12

–

LUBRICATION SYSTEM

Oil Pump

DISASSEMBLY OF OIL PUMP

(See Components on page

1.

REMOVE RELIEF VALVE

(a) Slighty mount the pump body in a vise.

(b) Remove the plug, gasket, compression spring and relief

valve.

NOTICE: Be careful not to damage the pump body.

2.

REMOVE DRIVE AND DRIVEN ROTORS

Remove the ten screws, pump body cover, the drive and

driven rotors.

INSPECTION OF OIL PUMP

1.

INSPECT RELIEF VALVE

Coat the valve with engine oil and check that it falls smoothly

into the valve hole on its own weight.

If it doesn’t, replace the relief valve. If necessary, replace the

oil pump assembly.

2.

INSPECT DRIVE AND DRIVEN ROTORS

A. Place drive and driven rotors into oil pump body

The marks on the rotors must face up.

B.

Inspect rotor tip clearance

Using a feeler gauge, measure the clearance between the

drive and driven rotors.

Standard tip clearance:

0.310–0.490 mm

(0.0122–0.0193 in.)

Maximum tip clearance: 0.53 mm (0.0209 in.)

If the tip clearance is greater than maximum, replace the ro-

tors as a set.

–

LUBRICATION SYSTEM

Oil Pump

LU–13

C. Inspect rotor body clearance

Using a feeler gauge, measure the clearance between the

driven rotor and pump body.

Standard body clearance:

0.100–0.175 mm

(0.0039–0.0069 in.)

Maximum body clearance: 0.20 mm (0.0079 in.)

If the body clearance is greater than maximum, replace the

rotors as a set. If necessary, replace the oil pump assembly.

D. Inspect rotor side clearance

Using a feeler gauge and precision straight edge, measure

the clearance between the rotors and precision straight

edge.

Standard side clearance:

0.030–0.090 mm

(0.0012–0.0035 in.)

Maximum side clearance:

0.12 mm (0.0047 in.)

If the side clearance is greater than maximum, replace the ro-

tors as a set. If necessary, replace the oil pump assembly.

E. Remove drive and driven rotors

REPLACEMENT OF CRANKSHAFT

FRONT OIL SEAL

(See page

ASSEMBLY OF OIL PUMP

(See Components on page

1.

INSTALL DRIVE AND DRIVEN ROTORS

(a) Place

the drive and driven rotors into oil pump body with

the mark facing upward.

(b) Install the pump body cover with the ten screws.

Torque: 10 N

⋅

m (105 kgf

⋅

cm, 8 ft

⋅

lbf)

LU–14

–

LUBRICATION SYSTEM

Oil Pump

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст