Lexus SC300 / Lexus SC400. Service manual — part 638

(c) Check the ignition timing.

Ignition timing: 8–12

°

BTDC @ idle

(Transmission in neutral range)

If the ignition timing is not as specified, check that following

conditions are normal:

•

Throttle valve fully closed

•

Continuity between terminals IDL1 and E2 of the

throttle position sensor (See page

)

•

(e) Remove the SST from the check connector.

SST 09843–18020

17. DISCONNECT TACHOMETER AND TIMING LIGHT FROM

ENGINE

18. INSTALL UPPER HIGH–TENSION CORD COVER

(See step 10 on pages

–

IGNITION SYSTEM

Distributor

IG–29

ENGINE SPEED SENSOR

COMPONENTS FOR REMOVAL AND

INSTALLATION

REMOVAL OF ENGINE SPEED SENSOR

1.

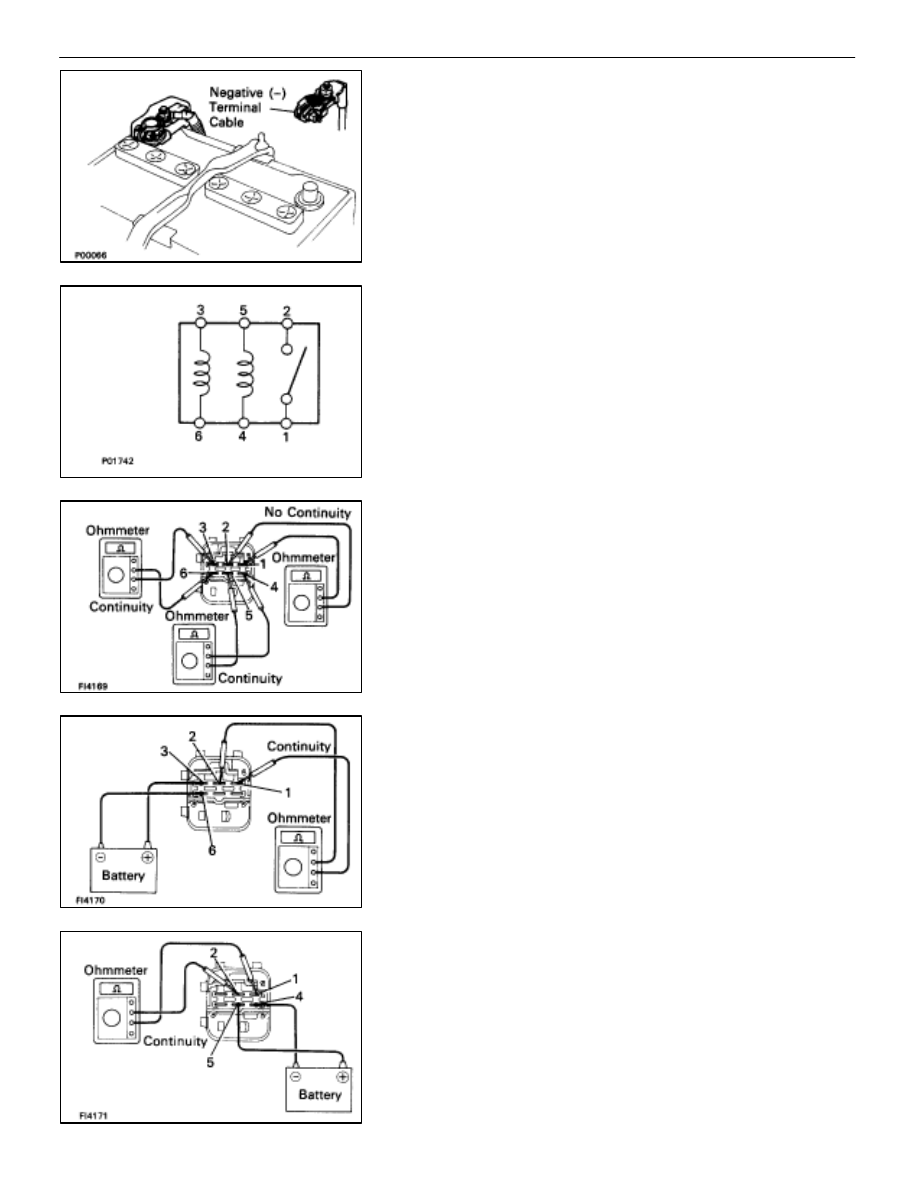

DISCONNECT CABLE FROM NEGATIVE TERMINAL OF

BATTERY

CAUTION: Work must be started after approx. 20 se-

conds or longer from the time the ignition switch is

turned to the ”LOCK” position and the negative (–) termi-

nal cable is disconnected from the battery.

2.

REMOVE ENGINE UNDER COVER

3.

DISCONNECT ENGINE SPEED SENSOR CONNECTOR

4.

REMOVE ENGINE SPEED SENSOR

Remove the bolt and engine speed sensor.

INSTALLATION OF ENGINE SPEED

SENSOR

1.

INSTALL ENGINE SPEED SENSOR

Torque: 6.4 N

⋅

m (65 kgf

⋅

cm, 56 in.

⋅

lbf)

2.

CONNECT ENGINE SPEED SENSOR CONNECTOR

3.

INSTALL ENGINE UNDER COVER

4. CONNECT CABLE TO NEGATIVE TERMINAL OF

BATTERY

IG–30

–

IGNITION SYSTEM

Engine Speed sensor

IGNITION MAIN RELAY

INSPECTION OF IGNITION MAIN RELAY

1.

DISCONNECT CABLE FROM NEGATIVE TERMINAL OF

BATTERY

CAUTION: Work must be started after approx. 20 se-

conds or longer from the time the ignition switch is

turned to the ”LOCK” position and the negative (–) termi-

nal cable is disconnected from the battery.

2.

REMOVE IGNITION MAIN RELAY

LOCATION: In the engine compartment relay box.

3.

INSPECT IGNITION MAIN RELAY

A. Inspect relay continuity

(a) Using an ohmmeter, check that there is continuity

between terminals 3 and 6.

(b) Check that there is continuity between terminals 4 and

5.

(c) Check that there is no continuity between terminals 1

and 2.

If continuity is not as specified, replace the relay.

B. Inspect relay operation

(a) Apply battery voltage across terminals 3 and 6.

(b) Using an ohmmeter, check that there is continuity

between terminals 1 and 2.

(c) Apply battery voltage across terminals 4 and 5.

(d) Using an ohmmeter, check that there is continuity

between terminals 1 and 2.

If operation is not as specified, replace the relay.

4.

REINSTALL IGNITION MAIN RELAY

5. RECONNECT CABLE TO NEGATIVE TERMINAL OF

BATTERY

–

IGNITION SYSTEM

Ignition Main Relay

IG–31

SERVICE SPECIFICATIONS

SERVICE DATA

Ignition timing

8–12

°

BTDC @ idle

g

g

(w/ Terminals TE1 and E1 connected)

Firing order

1–8–4–3–6–5–7–2

Spark plug

Type

ND

PK20R11

g

NGK

BKR6EP11

Electrode gap

New plug

STD

1.1 mm

0.043 in.

Used plug

Limit

1.3 mm

0.051 in.

High–tension

Resistance

25 k

per cord

g

cord

Ignition coil

Primary coil resistance

0.40–0.50

g

y

Secondary coil resistance

10.0–14.0 k

Cam position

Resistance

at –10– +40

°

C (14–104

°

F)

835–1,350

sensor

Engine speed

Resistance

at –10– +40

°

C (14–104

°

F)

835–1,350

sensor

TORQUE SPECIFICATIONS

Part tightened

N

⋅

m

kgf

⋅

cm

ft

⋅

lbf

Spark plug X Cylinder head

18

180

13

Cam position sensor X Distributor housing

18

185

13

Distributor cap X Distributor housing

3.8

39

34 in.

⋅

lbf

Distributor rotor X Camshaft timing pulley

3.8

39

34 in.

⋅

lbf

RH No.2 timing belt cover X Cylinder block (for 12 mm head)

16

160

12

Drive belt idler pulley X Hydraulic pump

37

380

27

Engine speed sensor X Oil pump

6.4

65

56 in.

⋅

lbf

IG–32

–

IGNITION SYSTEM

Service Specifications

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст