Lexus SC300 / Lexus SC400. Service manual — part 522

SERVICE SPECIFICATIONS

SERVICE DATA

Ignition timing

8–12

°

BTDC @ idle

g

g

(w/ Terminals TE1 and E1 connected)

Firing order

1–8–4–3–6–5–7–2

Spark plug

Type

ND

PK20R11

g

NGK

BKR6EP11

Electrode gap

New plug

STD

1.1 mm

0.043 in.

Used plug

Limit

1.3 mm

0.051 in.

High–tension

Resistance

25 k

per cord

g

cord

Ignition coil

Primary coil resistance

0.40–0.50

g

y

Secondary coil resistance

10.0–14.0 k

Cam position

Resistance

at –10– +40

°

C (14–104

°

F)

835–1,350

sensor

Engine speed

Resistance

at –10– +40

°

C (14–104

°

F)

835–1,350

sensor

TORQUE SPECIFICATIONS

Part tightened

N

⋅

m

kgf

⋅

cm

ft

⋅

lbf

Spark plug X Cylinder head

18

180

13

Cam position sensor X Distributor housing

18

185

13

Distributor cap X Distributor housing

3.8

39

34 in.

⋅

lbf

Distributor rotor X Camshaft timing pulley

3.8

39

34 in.

⋅

lbf

RH No.2 timing belt cover X Cylinder block (for 12 mm head)

16

160

12

Drive belt idler pulley X Hydraulic pump

37

380

27

Engine speed sensor X Oil pump

6.4

65

56 in.

⋅

lbf

IG–32

–

IGNITION SYSTEM

Service Specifications

IGNITION SYSTEM

IG–1

IGNITION SYSTEM

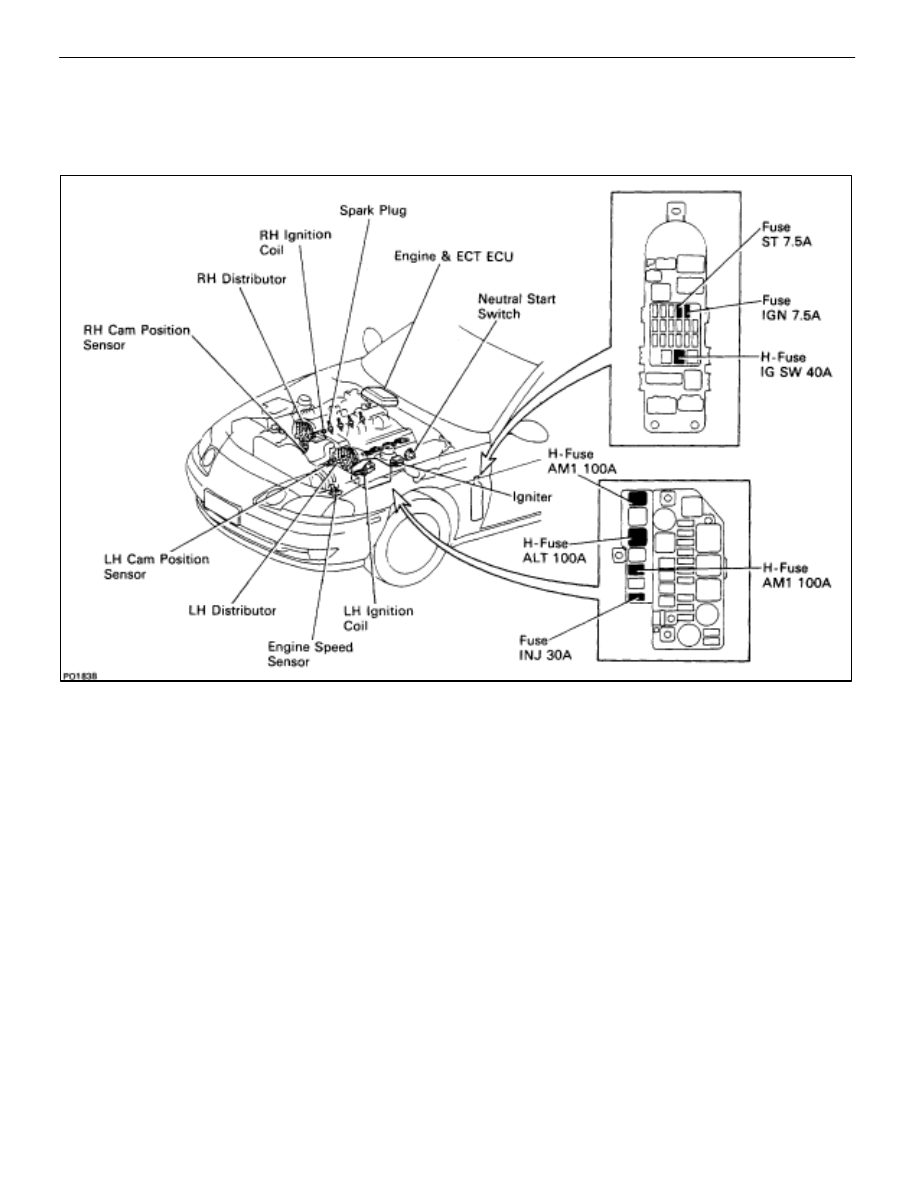

DESCRIPTION

The ECU is programmed with data for optimum ignition timing under any and all operating conditions. Using

data provided by sensors which monitor various engine functions (rpm, intake air volume, engine temperature,

etc.) the microcomputer (ECU) triggers the spark at precisely the right instant.

The ECU monitors the engine condition by signals from each sensor, calculates the ignition timing and sends

an ignition signal to the igniter. High voltage from the ignition is distributed to each spark plug in the appropriate

order to generate a spark between the electrodes, which ignites the air–fuel mixture.

IGNITERS

The igniter temporarily interrupts the primary current with the ignition signal (IGT signal) from the ECU and

generates sparks at the spark plug. Also, as a fail–safe measure, when ignition occurs, an ignition confirmation

signal (IGF signal) is sent to the ECU.

IGNITION COIL

The ignition coil uses a closed core coil with the primary coil wrapped around the core and the secondary

coil wrapped around the primary coil. This allows the generation of a high voltage sufficient to cause a spark

to jump across the spark plug gap.

DISTRIBUTORS

This correctly distributes high voltage to the spark plug of each cylinder in the specified ignition order.

ENGINE SPEED SENSOR

The engine speed sensor detects the crank angle.

CAM POSITION SENSORS

The RH and LH cam position sensors detect the cam angle.

IG–2

–

IGNITION SYSTEM

Description

PRECAUTIONS

1. Do not leave the ignition switch on for more than 10

minutes if the engine will not start.

2.

With a tachometer connected to the system, connect the

tester probe of the tachometer to terminal IG È of the

check (”DIAGNOSIS”) connector.

HINT:

•

Allow the engine to warm up to normal operation

temperature.

•

Set the tachometer to the 4–cylinder range.

3. As some tachometers are not compatible with this

ignition system, we recommend that you confirm the

compatibility of your unit before use.

4.

Never allow the tachometer terminal to touch ground as

this could damage the igniter and/or ignition coil.

5. Do not disconnect the battery when the engine is

running.

6.

Check that the igniter is properly grounded to the body.

–

IGNITION SYSTEM

Precautions

IG–3

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст