Lexus ES300 (1997 year). Service manual — part 527

S05036

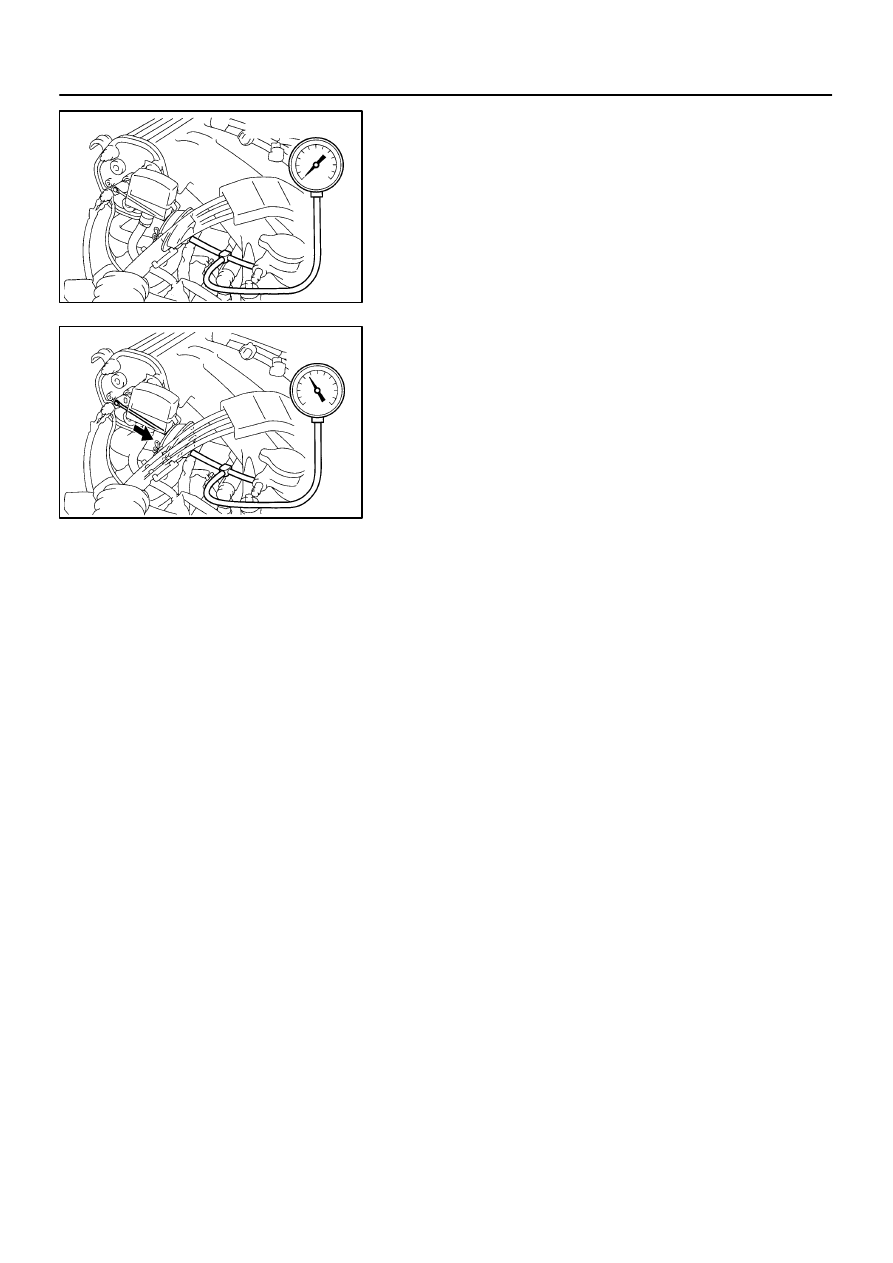

Vacuum Gauge

SF06B–01

S05037

Approx.

26.7 kPa

Pull

SF–42

–

SFI

ACOUSTIC CONTROL INDUCTION SYSTEM (ACIS)

893

1997 LEXUS ES300 (RM511U)

ACOUSTIC CONTROL INDUCTION

SYSTEM (ACIS)

ON–VEHICLE INSPECTION

INSPECT INTAKE AIR CONTROL VALVE

(a)

Using a 3–way connector, connect vacuum gauge to the

actuator hose.

(b)

Start the engine.

(c)

While the engine is idling, check that the vacuum gauge

needle does not move.

(d)

Rapidly depress the accelerator pedal to fully open posi-

tion and check that the vacuum gauge needle momentari-

ly fluctuates up to approx. 26.7 kPa (200 mmHg, 7.9

in.Hg). (The actuator rod is pulled out.)

SF06C–04

S05108

Intake Air Control Valve

DLC1 Bracket

DLC1

Gasket

Actuator Vacuum Hose

Ground Strap

Ground Cable

N·m (kgf·cm, ft·lbf)

: Specified torque

Non–reusable part

14.5 (145, 10)

–

SFI

ACOUSTIC CONTROL INDUCTION SYSTEM (ACIS)

SF–43

894

1997 LEXUS ES300 (RM511U)

COMPONENTS

SF06D–01

S05033

(2)

(1)

S05032

SF–44

–

SFI

ACOUSTIC CONTROL INDUCTION SYSTEM (ACIS)

895

1997 LEXUS ES300 (RM511U)

REMOVAL

1.

DISCONNECT ACTUATOR VACUUM HOSE

2.

DISCONNECT DLC1 FROM DLC1 BRACKET

3.

REMOVE INTAKE AIR CONTROL VALVE

(a)

Remove the 4 nuts and DLC1 bracket, and disconnect the

ground strap and cable.

(b)

Remove the intake air control valve by prying a screwdriv-

er between the intake air control valve and air intake

chamber.

(c)

Remove the gasket.

SF06E–01

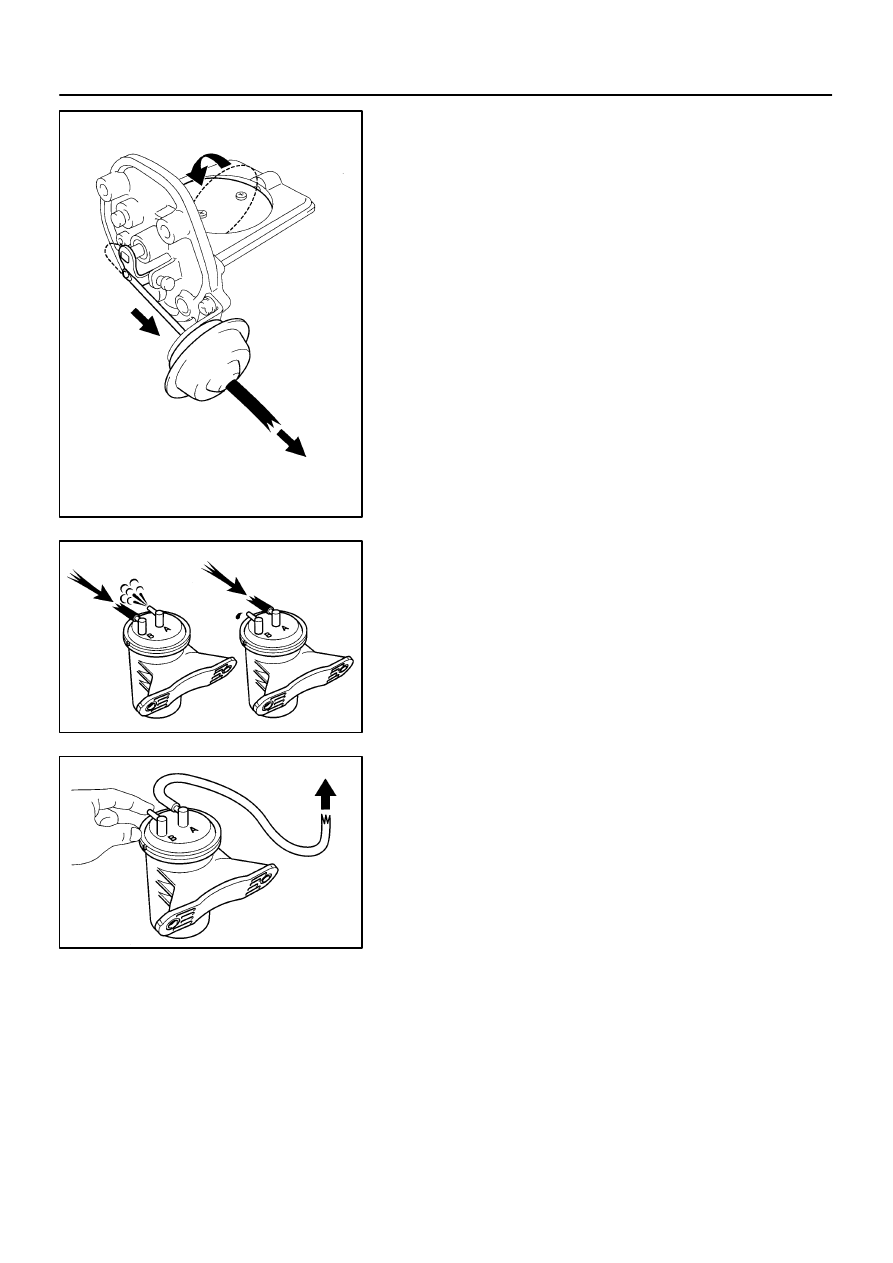

S05041

Vacuum

S05689

Air

Air

S05688

Vacuum

–

SFI

ACOUSTIC CONTROL INDUCTION SYSTEM (ACIS)

SF–45

896

1997 LEXUS ES300 (RM511U)

INSPECTION

1.

INSPECT INTAKE AIR CONTROL VALVE

(a)

With 26.7 kPa (200 mmHg, 7.9 in.Hg) of vacuum applied

to the actuator, check that the actuator rod moves.

(b)

One minute after applying the vacuum in (a), check that

the actuator rod does not return.

If the operation is not as specified, replace the intake air control

valve.

2.

INSPECT VACUUM TANK

LOCATION: The LH side member under the battery

tray.

(a)

Check that air flows from port B to port A.

(b)

Check that air does not flow from port A to port B.

(c)

Plug port B with your finger, and apply 26.7 kPa (200

mmHg, 7.9 in.Hg) of vacuum to port A, and check that

there is no change is vacuum after one minute.

If the operation is not as specified, replace the vacuum tank.

3.

INSPECT VSV (See page

)

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст