Nissan Pathfinder (2012 year). Instruction — part 393

2012

QUICK REFERENCE CHART: PATHFINDER

Brake Specifications

INFOID:0000000007837578

Unit: mm (in)

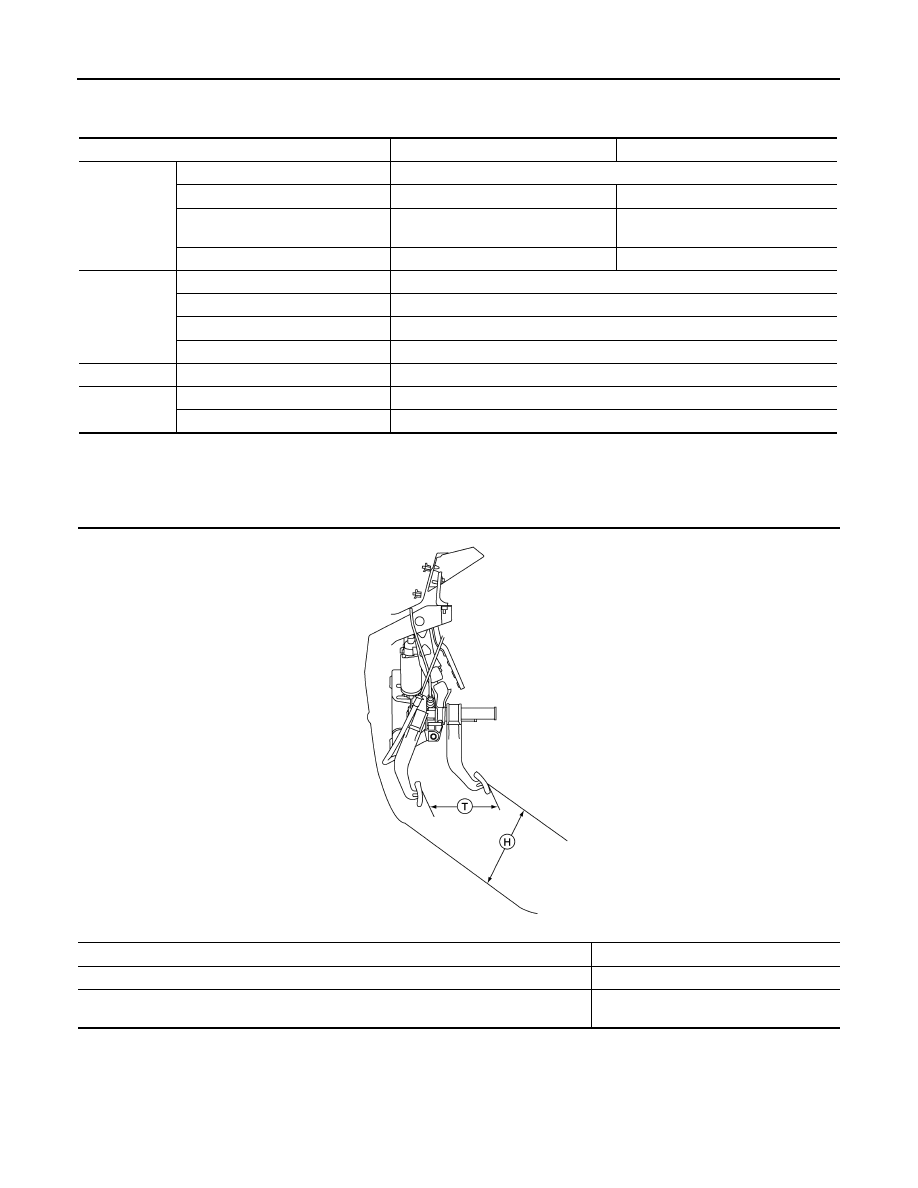

Brake Pedal

INFOID:0000000007837579

ADJUSTABLE PEDAL

Unit: mm (in)

CAUTION:

When equipped with adjustable pedal, the pedal must be in the forward most position (closest to the floor) for pedal height

adjustment.

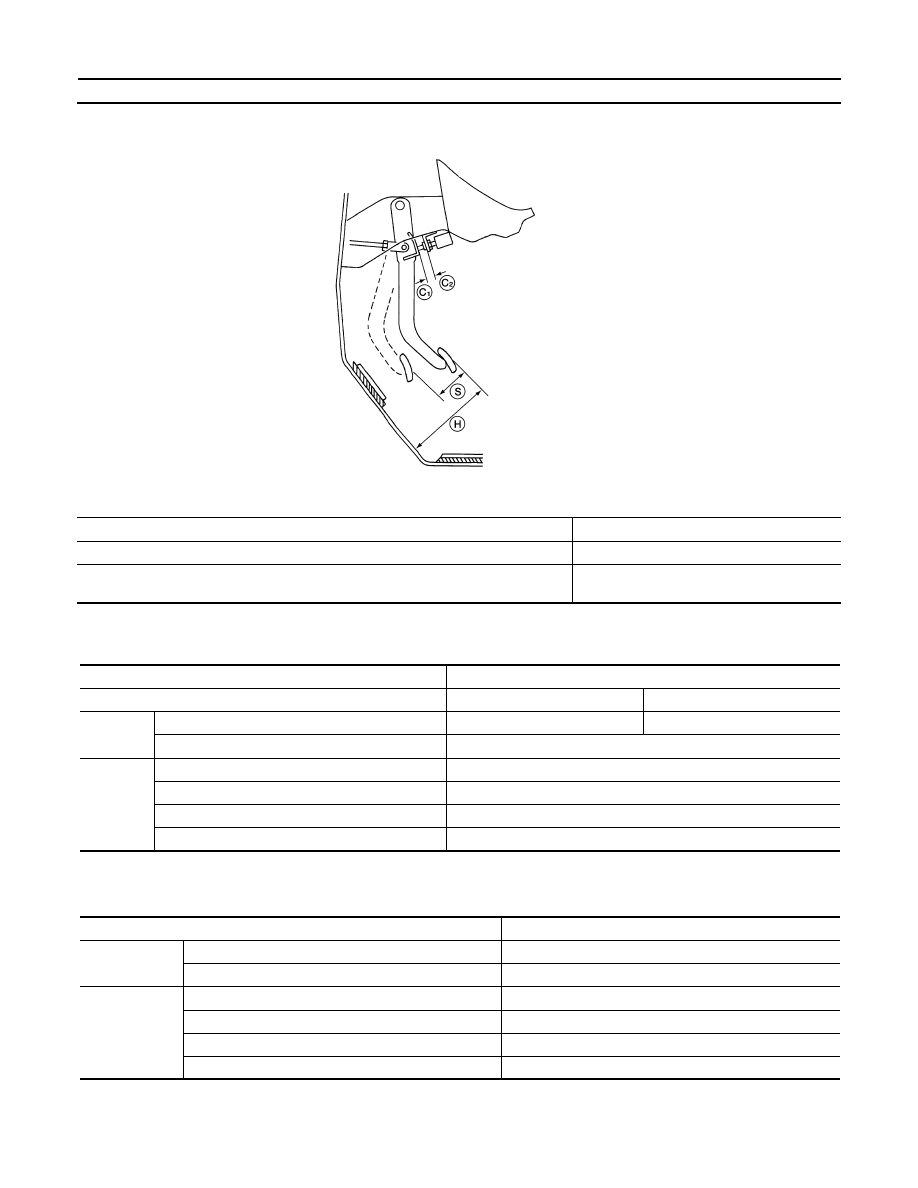

STANDARD PEDAL

Application

VQ40DE

VK56DE

Front brake

Brake model

CLZ33VB

Rotor outer diameter

×

thickness

296

×

28 (11.654

×

1.102)

320 x 28 (12.598 x 1.102)

Pad Length

×

width

×

thickness

140

×

50.5

×

10.0 (5.512

×

1.988

×

0.394)

130

×

52.3

×

11.0 (5.118

×

2.059

×

0.433)

Cylinder bore diameter (each)

46.4 (1.827)

45.0 (1.772)

Rear brake

Brake model

CLZ14VB

Rotor outer diameter

×

thickness

308

×

18 (12.126

×

0.709)

Pad Length

×

width

×

thickness

87.6

×

37.0

×

11.0 (3.449

×

1.457

×

0.433)

Cylinder bore diameter

38.1 (1.500)

Control valve

Valve model

Electric brake force distribution

Brake booster

Booster model

C215T

Diaphragm diameter

215 (8.465)

Pedal free height (H) with pedal in forward most position

182.1 (7.17)

Pedal full stroke (T)

153 (6.02)

Clearance between brake pedal bracket and threaded end of stop lamp switch and ASCD

cancel switch

0.74 - 1.96 (0.029 - 0.077)

ALFIA0149ZZ

QUICK REFERENCE CHART: PATHFINDER

2012

Unit: mm (in)

Front Disc Brake

INFOID:0000000007837576

Unit: mm (in)

Rear Disc Brake

INFOID:0000000007837577

Unit: mm (in)

Pedal free height (H)

182.1 (7.17)

Pedal full stroke (S)

153 (6.02)

Clearance between brake pedal bracket (C

1

) and threaded end of stop lamp switch and

ASCD cancel switch (C

2

)

0.74 - 1.96 (0.029 - 0.077)

AWFIA0433ZZ

Brake model

CLZ33VB

Application

VQ40DE

VQ56DE

Brake pad

Standard thickness (new)

10.0 (0.394)

11.0 (0.043)

Minimum thickness

2.0 (0.079)

Disc rotor

Standard thickness (new)

28.0 (1.102)

Minimum thickness

26.0 (1.024)

Maximum uneven wear (measured at 8 positions)

0.015 (0.0006)

Runout limit (with it attached to the vehicle)

0.05 (0.0020)

Brake model

CLZ14VB

Brake pad

Standard thickness (new)

11.0 (0.433)

Minimum thickness

2.0 (0.079)

Disc rotor

Standard thickness (new)

18.0 (0.709)

Minimum thickness

16.0 (0.630)

Maximum uneven wear (measured at 8 positions)

0.015 (0.0006)

Runout limit (with it attached to the vehicle)

0.05 (0.0020)

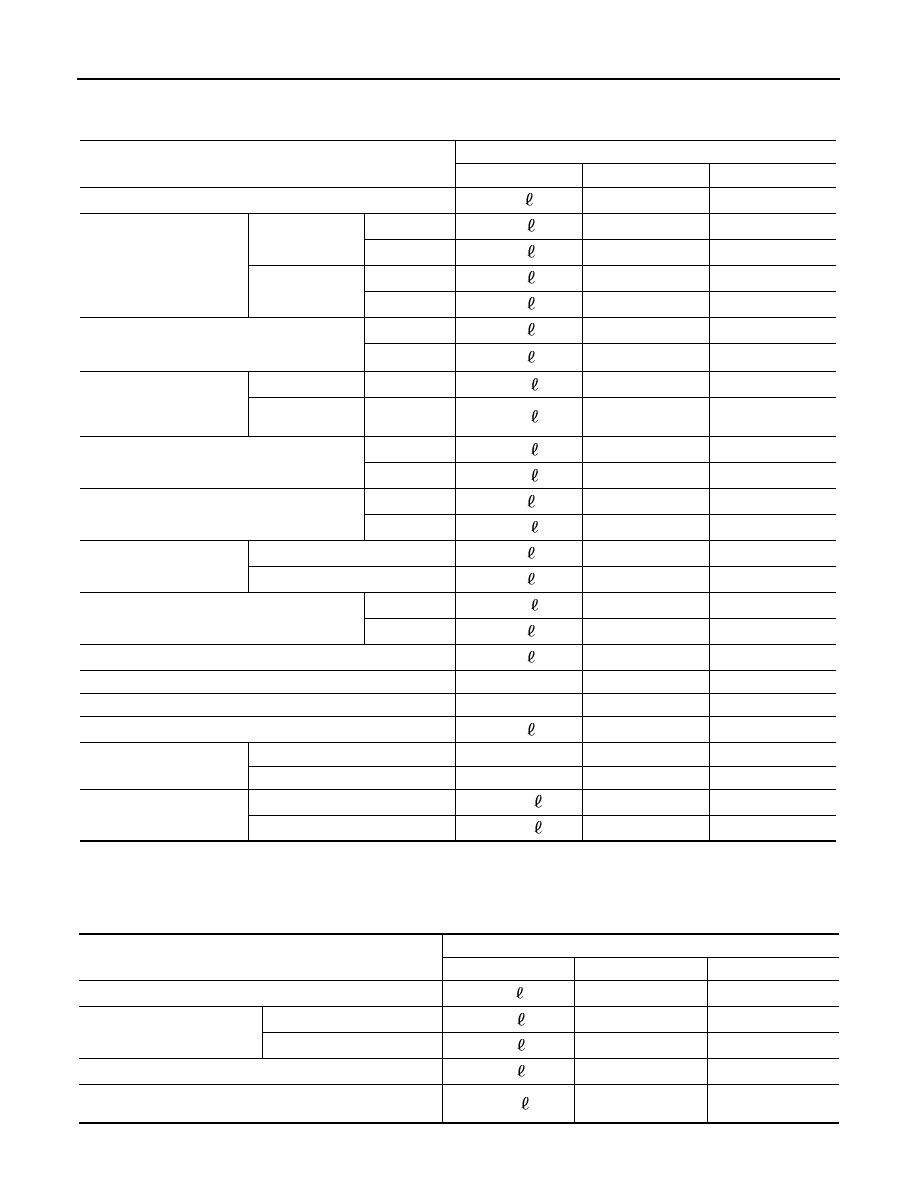

2012

QUICK REFERENCE CHART: PATHFINDER

FOR USA AND CANADA : Fluids and Lubricants

INFOID:0000000007837569

FOR MEXICO

FOR MEXICO : Fluids and Lubricants

INFOID:0000000007837572

Description

Capacity (Approximate)

Metric

US measure

Imp measure

Fuel

80

21 1/8 gal

17 5/8 gal

Engine oil

Drain and refill

With oil filter

change

VQ40DE

5.1

5 3/8 qt

4 1/2 qt

VK56DE

6.5

6 7/8 qt

5 3/4 qt

Without oil filter

change

VQ40DE

4.8

5 1/8 qt

4 1/4 qt

VK56DE

6.2

6 1/2 qt

5 1/2 qt

Dry engine (engine overhaul)

VQ40DE

6.3

6 5/8 qt

5 1/2 qt

VK56DE

7.6

8 qt

6 3/4 qt

Cooling system

(with reservoir at “MAX” lev-

el)

Without rear A/C

VQ40DE

10.2

10 3/4 qt

9 qt

With rear

A/C

VQ40DE

VK56DE

13.4

14 1/8 qt

11 3/4 qt

Automatic transmission fluid (ATF)

VQ40DE

10.3

10 7/8 qt

9 1/8 qt

VK56DE

10.6

11 1/4 qt

9 3/8 qt

Rear final drive oil

VQ40DE

1.4

3 pt

2 1/2 pt

VK56DE

1.75

3 3/4 pt

3 1/8 pt

Transfer fluid

ATX14B

3.0

3 1/8 qt

2 5/8 qt

TX15B

2.0

2 1/8 qt

1 3/4 qt

Front final drive oil

VQ40DE

0.85

1 3/4 pt

1 1/2 pt

VK56DE

1.6

3 3/8 pt

2 7/8 pt

Power steering fluid (PSF)

1.0

2 1/8 pt

1 3/4 pt

Brake fluid

—

—

—

Multi-purpose grease

—

—

—

Windshield washer fluid

4.5

1 1/4 gal

1 gal

A/C system

refrigerant

Without rear A/C

0.70

±

0.05 kg

1.54

±

0.11 lb

1.54

±

0.11 lb

With rear A/C

0.85

±

0.05 kg

1.87

±

0.11 lb

1.87

±

0.11 lb

A/C system oil

Without rear A/C

180 m

6.1 fl oz

6.3 fl oz

With Rear A/C

210 m

7.1 fl oz

7.4 fl oz

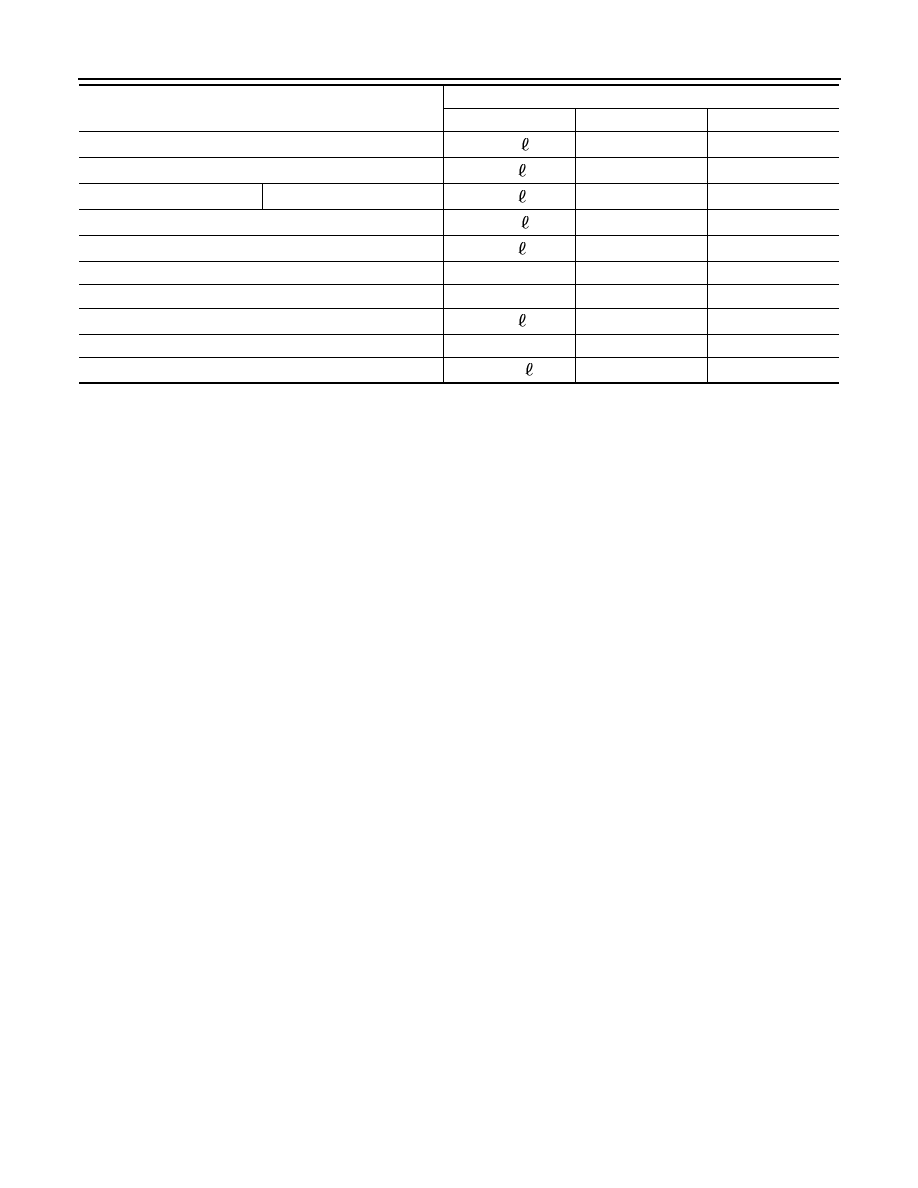

Description

Capacity (Approximate)

Metric

US measure

Imp measure

Fuel

80

21 1/8 gal

17 5/8 gal

Engine oil

Drain and refill

With oil filter change

5.1

5 3/8 qt

4 1/2 qt

Without oil filter change

4.8

5 1/8 qt

4 1/4 qt

Dry engine (engine overhaul)

6.3

6 5/8 qt

5 1/2 qt

Cooling system

(with reservoir at “MAX” level)

13.4

14 1/8 qt

11 3/4 qt

QUICK REFERENCE CHART: PATHFINDER

2012

Automatic transmission fluid (ATF)

10.3

10 7/8 qt

9 1/8 qt

Rear final drive oil

1.4

3 pt

2 1/2 pt

Transfer fluid

ATX14B

3.0

3 1/8 qt

2 5/8 qt

Front final drive oil

0.85

1 3/4 pt

1 1/2 pt

Power steering fluid (PSF)

1.0

2 1/8 pt

1 3/4 pt

Brake fluid

—

—

—

Multi-purpose grease

—

—

—

Windshield washer fluid

4.5

1 1/4 gal

1 gal

A/C system refrigerant

0.85

±

0.05 kg

1.87

±

0.11 lb

1.87

±

0.11 lb

A/C system oil

210 m

7.1 fl oz

7.4 fl oz

Description

Capacity (Approximate)

Metric

US measure

Imp measure

GI-1

GENERAL INFORMATION

C

D

E

F

G

H

I

J

K

L

M

B

GI

SECTION

GI

N

O

P

CONTENTS

GENERAL INFORMATION

HOW TO USE THIS MANUAL . . . . . ..

HOW TO USE THIS MANUAL . . . . . . .

Description . . . . . . . . . . . . . . . ....

Terms . . . . . . . . . . . . . . . . . ....

Units . . . . . . . . . . . . . . . . . . ..

Contents . . . . . . . . . . . . . . . . ....

Relation between Illustrations and Descriptions . ...

Components . . . . . . . . . . . . . . . ..

HOW TO FOLLOW TROUBLE DIAGNOSES . .

Description . . . . . . . . . . . . . . . ....

How to Follow Test Groups in Trouble Diagnosis . ..

Key to Symbols Signifying Measurements or Pro-

cedures . . . . . . . . . . . . . . . . .....

HOW TO READ WIRING DIAGRAMS . . . .

Connector symbols . . . . . . . . . . . . ...

Sample/wiring diagram -example- . . . . . . ...

Description . . . . . . . . . . . . . . . ..

ABBREVIATIONS . . . . . . . . . . . ..

Abbreviation List . . . . . . . . . . . . . ..

RECOMMENDED CHEMICAL PRODUCTS

AND SEALANTS . . . . . . . . . . . .

Recommended Chemical Products and Sealants .

TERMINOLOGY . . . . . . . . . . . . .

ISO 15031-2 Terminology List . . . . . . . .

TIGHTENING TORQUE OF STANDARD

BOLTS . . . . . . . . . . . . . . . .

Tightening Torque Table . . . . . . . . . . .

FEATURES OF NEW MODEL . . . . . .

IDENTIFICATION INFORMATION . . . . . .

Model Variation . . . . . . . . . . . . . ...

Identification Number . . . . . . . . . . . ..

Dimensions . . . . . . . . . . . . . . . .

Wheels & Tires . . . . . . . . . . . . . .

PRECAUTION . . . . . . . . . . . ..

PRECAUTIONS . . . . . . . . . . . . .

Description . . . . . . . . . . . . . . . ...

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect . . . . . . . . ...

General Precaution . . . . . . . . . . . . ..

Precaution for All Mode 4WD System . . . . . .

Precaution for Three Way Catalyst . . . . . . ..

Precaution for Fuel (Unleaded Premium Gasoline

Recommended) . . . . . . . . . . . . . ...

Precaution for Multiport Fuel Injection System or

Engine Control System . . . . . . . . . . .

Precaution for Hoses . . . . . . . . . . . ...

Precaution for Engine Oils . . . . . . . . . ...

Precaution for Air Conditioning . . . . . . . .

LIFTING POINT . . . . . . . . . . . . .

Pantograph Jack . . . . . . . . . . . . . ..

Garage Jack and Safety Stand . . . . . . . .

2-Pole Lift . . . . . . . . . . . . . . . .

TOW TRUCK TOWING . . . . . . . . . .

Tow Truck Towing . . . . . . . . . . . . ...

Vehicle Recovery (Freeing a Stuck Vehicle) . . ...

BASIC INSPECTION . . . . . . . . ...

SERVICE INFORMATION FOR ELECTRICAL

INCIDENT . . . . . . . . . . . . . . ..

Work Flow . . . . . . . . . . . . . . . .

Control Units and Electrical Parts . . . . . . .

How to Check Terminal . . . . . . . . . . ...

Intermittent Incident . . . . . . . . . . . . .

Circuit Inspection . . . . . . . . . . . . . .

CONSULT CHECKING SYSTEM . . . . . .

Description . . . . . . . . . . . . . . . ...

Function and System Application . . . . . . .

August 2012

2012 Pathfinder

GI-2

CONSULT Data Link Connector (DLC) Circuit . ...

WIRING DIAGRAM . . . . . . . . . .

CONSULT CHECKING SYSTEM . . . . . ..

Wiring Diagram . . . . . . . . . . . . . ...

August 2012

2012 Pathfinder

HOW TO USE THIS MANUAL

GI-3

< HOW TO USE THIS MANUAL >

C

D

E

F

G

H

I

J

K

L

M

B

GI

N

O

P

HOW TO USE THIS MANUAL

HOW TO USE THIS MANUAL

Description

INFOID:0000000007359054

This volume explains “Removal, Disassembly, Installation, Inspection and Adjustment” and “Trouble Diag-

noses”.

Terms

INFOID:0000000007359055

• The captions

WARNING

and

CAUTION

warn you of steps that must be followed to prevent personal injury

and/or damage to some part of the vehicle.

WARNING

indicates the possibility of personal injury if instructions are not followed.

CAUTION

indicates the possibility of component damage if instructions are not followed.

BOLD TYPED STATEMENTS

except

WARNING

and

CAUTION

give you helpful information.

Standard value:Tolerance at inspection and adjustment.

Limit value:The maximum or minimum limit value that should not be exceeded at inspection and adjustment.

Units

INFOID:0000000007359056

• The

UNITS

given in this instruction are primarily expressed as the SI UNIT (International System of Unit), and

alternatively expressed in the metric system and in the yard/pound system.

Also with regard to tightening torque of bolts and nuts, there are descriptions both about range and about the

standard tightening torque.

“Example”

Range

Standard

Contents

INFOID:0000000007359057

•

A QUICK REFERENCE INDEX

, a black tab (e.g.

) is provided on the first page. You can quickly find the

first page of each section by matching it to the section's black tab.

•

THE CONTENTS

are listed on the first page of each section.

•

THE TITLE

is indicated on the upper portion of each page and shows the part or system.

•

THE PAGE NUMBER

of each section consists of two or three letters which designate the particular section

and a number (e.g. “BR-5”).

•

THE SMALL ILLUSTRATIONS

show the important steps such as inspection, use of special tools, knacks of

work and hidden or tricky steps which are not shown in the previous large illustrations.

Assembly, inspection and adjustment procedures for the complicated units such as the automatic transaxle

or transmission, etc. are presented in a step-by-step format where necessary.

Outer Socket Lock Nut

: 59 - 78 N·m (6.0 - 8.0 kg-m, 43 - 58 ft-lb)

Drive Shaft Installation Bolt : 44.3 N·m (4.5 kg-m, 33 ft-lb)

August 2012

2012 Pathfinder

GI-4

< HOW TO USE THIS MANUAL >

HOW TO USE THIS MANUAL

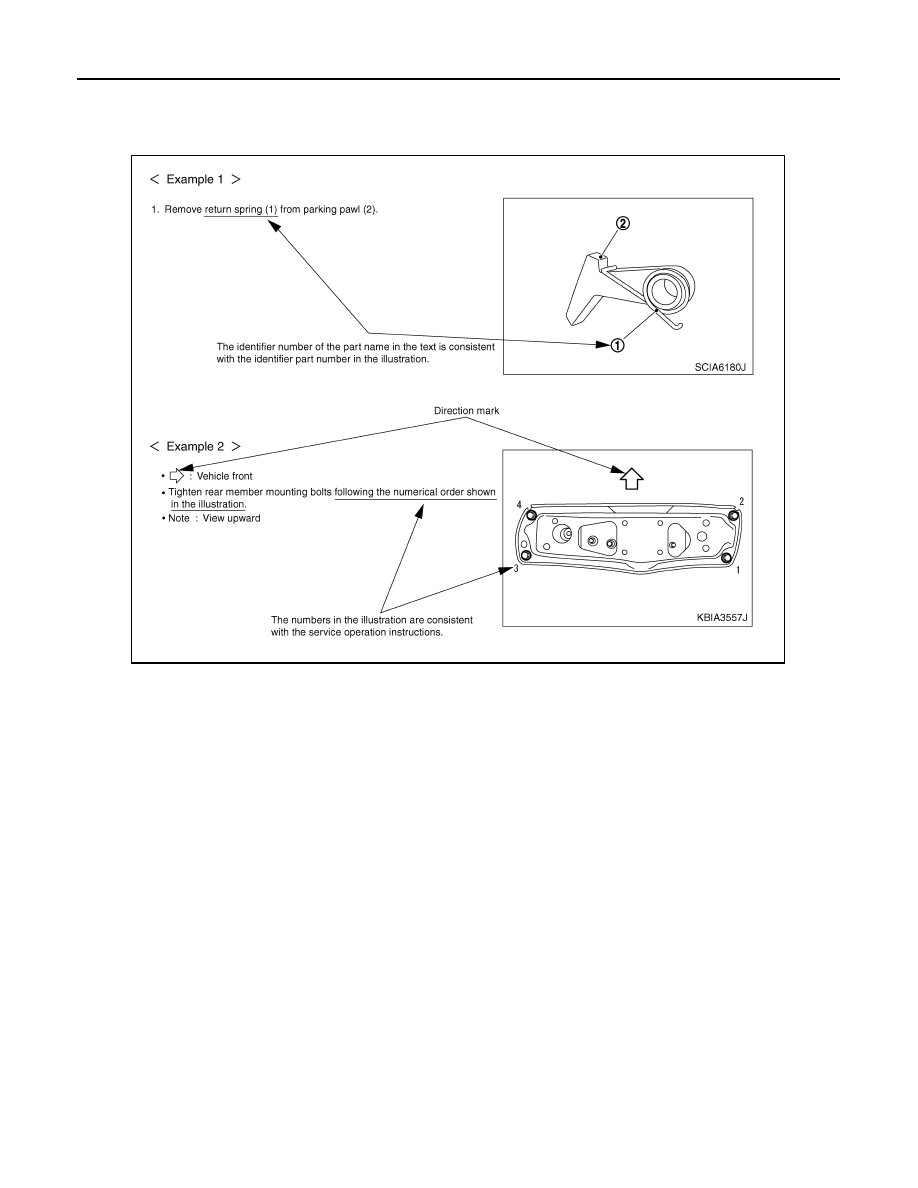

Relation between Illustrations and Descriptions

INFOID:0000000007359058

The following sample explains the relationship between the part description in an illustration, the part name in

the text and the service procedures.

Components

INFOID:0000000007359059

•

THE LARGE ILLUSTRATIONS

are exploded views (see the following) and contain tightening torques, lubri-

cation points, section number of the

PARTS CATALOG

(e.g. SEC. 440) and other information necessary to

perform repairs.

The illustrations should be used in reference to service matters only. When ordering parts, refer to the appro-

priate

PARTS CATALOG

.

Always check with the

PARTS DEPARMENT

for the latest parts information.

Components shown in an illustration may be identified by a circled number. When this style of illustration is

used, the text description of the components will follow the illustration.

SAIA0519E

August 2012

2012 Pathfinder

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст