Nissan Qashqai (2007-2010). Manual — part 398

P1111 IVT CONTROL SOLENOID VALVE

EC-1111

< COMPONENT DIAGNOSIS >

[MR20DE (WITHOUT EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

M

A

EC

N

P

O

Check the following.

• Harness connectors E7, F121

• Harness for open or short between intake valve timing control solenoid valve and IPDM E/R

>> Repair or replace harness or connectors.

3.

CHECK INTAKE VALVE TIMING CONTROL SOLENOID VALVE OUTPUT SIGNAL CIRCUIT FOR OPEN

AND SHORT

1.

Turn ignition switch OFF.

2.

Disconnect ECM harness connector.

3.

Check the continuity between intake valve timing control solenoid valve harness connector and ECM har-

ness connector.

4.

Also check harness for short to ground and short to power.

Is the inspection result normal?

YES

>> GO TO 4.

NO

>> Repair open circuit or short to ground or short to power in harness or connectors.

4.

CHECK INTAKE VALVE TIMING CONTROL SOLENOID VALVE

EC-1114, "Component Inspection"

.

Is the inspection result normal?

YES

>> GO TO 5.

NO

>> Replace intake valve timing control solenoid valve.

5.

CHECK INTERMITTENT INCIDENT

GI-39, "Intermittent Incident"

.

>> INSPECTION END

Component Inspection

INFOID:0000000001094185

1.

CHECK INTAKE VALVE TIMING CONTROL SOLENOID VALVE-I

1.

Turn ignition switch OFF.

2.

Disconnect intake valve timing control solenoid valve harness connector.

3.

Check resistance between intake valve timing control solenoid valve terminals as follows.

Is the inspection result normal?

YES

>> GO TO 2.

NO

>> Replace intake valve timing control solenoid valve.

2.

CHECK INTAKE VALVE TIMING CONTROL SOLENOID VALVE-II

1.

Remove intake valve timing control solenoid valve.

IVT control solenoid valve

ECM

Continuity

Connector

Terminal

Connector

Terminal

F41

1

F8

73

Existed

Terminals

Resistance [at 20

°

C (68

°

F)]

1 and 2

6.7 - 7.7

Ω

1 or 2 and ground

∞

Ω

(Continuity should not exist)

EC-1112

< COMPONENT DIAGNOSIS >

[MR20DE (WITHOUT EURO-OBD)]

P1111 IVT CONTROL SOLENOID VALVE

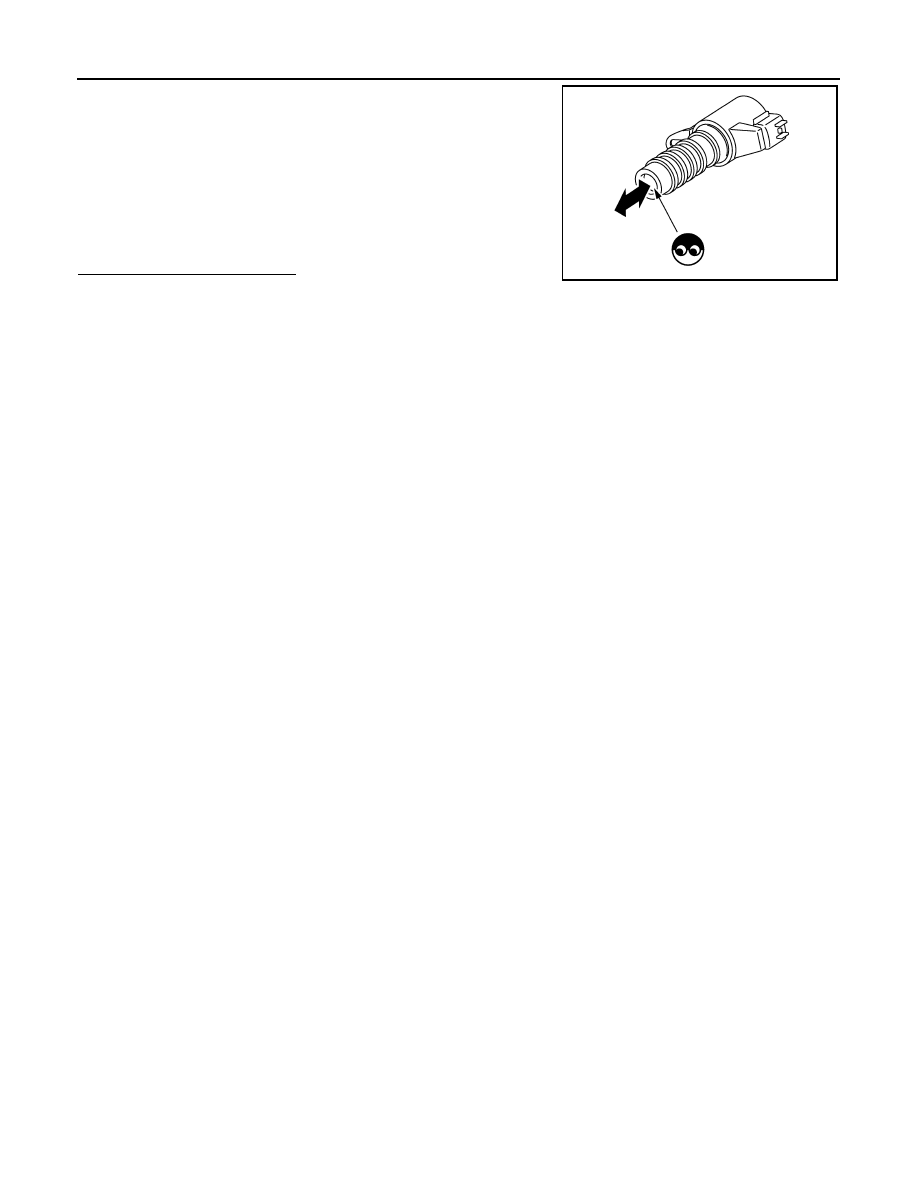

2.

Provide 12V DC between intake valve timing control solenoid

valve terminals 1 and 2, and then interrupt it. Make sure that the

plunger moves as shown in the figure.

CAUTION:

Do not apply 12V DC continuously for 5 seconds or more.

Doing so may result in damage to the coil in intake valve

timing control solenoid valve.

NOTE:

Always replace O-ring when intake valve timing control

solenoid valve is removed.

Is the inspection result normal?

YES

>> INSPECTION END

NO

>> Replace intake valve timing control solenoid valve.

JMBIA0350ZZ

P1121 ELECTRIC THROTTLE CONTROL ACTUATOR

EC-1113

< COMPONENT DIAGNOSIS >

[MR20DE (WITHOUT EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

M

A

EC

N

P

O

P1121 ELECTRIC THROTTLE CONTROL ACTUATOR

Description

INFOID:0000000001094186

Electric throttle control actuator consists of throttle control motor, throttle position sensor, etc.

The throttle control motor is operated by the ECM and it opens and closes the throttle valve.

The throttle position sensor detects the throttle valve position, and the opening and closing speed of the throt-

tle valve and feeds the voltage signals to the ECM. The ECM judges the current opening angle of the throttle

valve from these signals and the ECM controls the throttle control motor to make the throttle valve opening

angle properly in response to driving condition.

DTC Logic

INFOID:0000000001094187

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.

PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

>> GO TO 2.

2.

PERFORM DTC CONFIRMATION PROCEDURE FOR MALFUNCTION A AND B

1.

Turn ignition switch ON and wait at least 1 second.

2.

Set shift lever to D (CVT) or 1st (M/T) position and wait at least 3 seconds.

3.

Set shift lever to P (CVT) or Neutral (M/T) position.

4.

Turn ignition switch OFF and wait at least 10 seconds.

5.

Turn ignition switch ON and wait at least 1 second.

6.

Set shift lever to D (CVT) or 1st (M/T) position and wait at least 3 seconds.

7.

Set shift lever to P (CVT) or Neutral (M/T) position.

8.

Turn ignition switch OFF, wait at least 10 seconds, and then turn ON.

9.

Check DTC.

Is DTC detected?

YES

>> Go to

EC-1116, "Diagnosis Procedure"

.

NO

>> GO TO 3.

3.

PERFORM DTC CONFIRMATION PROCEDURE FOR MALFUNCTION C

1.

Turn ignition switch ON and wait at least 1 second.

2.

Set shift lever to D (CVT) or 1st (M/T) position and wait at least 3 seconds.

3.

Set shift lever to N, P (CVT) or Neutral (M/T) position.

4.

Start engine and let it idle for 3 seconds.

5.

Check DTC.

Is DTC detected?

YES

>> Go to

EC-1116, "Diagnosis Procedure"

.

NO

>> INSPECTION END

Diagnosis Procedure

INFOID:0000000001094188

1.

CHECK ELECTRIC THROTTLE CONTROL ACTUATOR VISUALLY

DTC No.

Trouble diagnosis name

DTC detecting condition

Possible cause

P1121

Electric throttle control

actuator

A)

Electric throttle control actuator does not func-

tion properly due to the return spring malfunc-

tion.

• Electric throttle control actuator

B)

Throttle valve opening angle in fail-safe mode is

not in specified range.

C)

ECM detect the throttle valve is stuck open.

EC-1114

< COMPONENT DIAGNOSIS >

[MR20DE (WITHOUT EURO-OBD)]

P1121 ELECTRIC THROTTLE CONTROL ACTUATOR

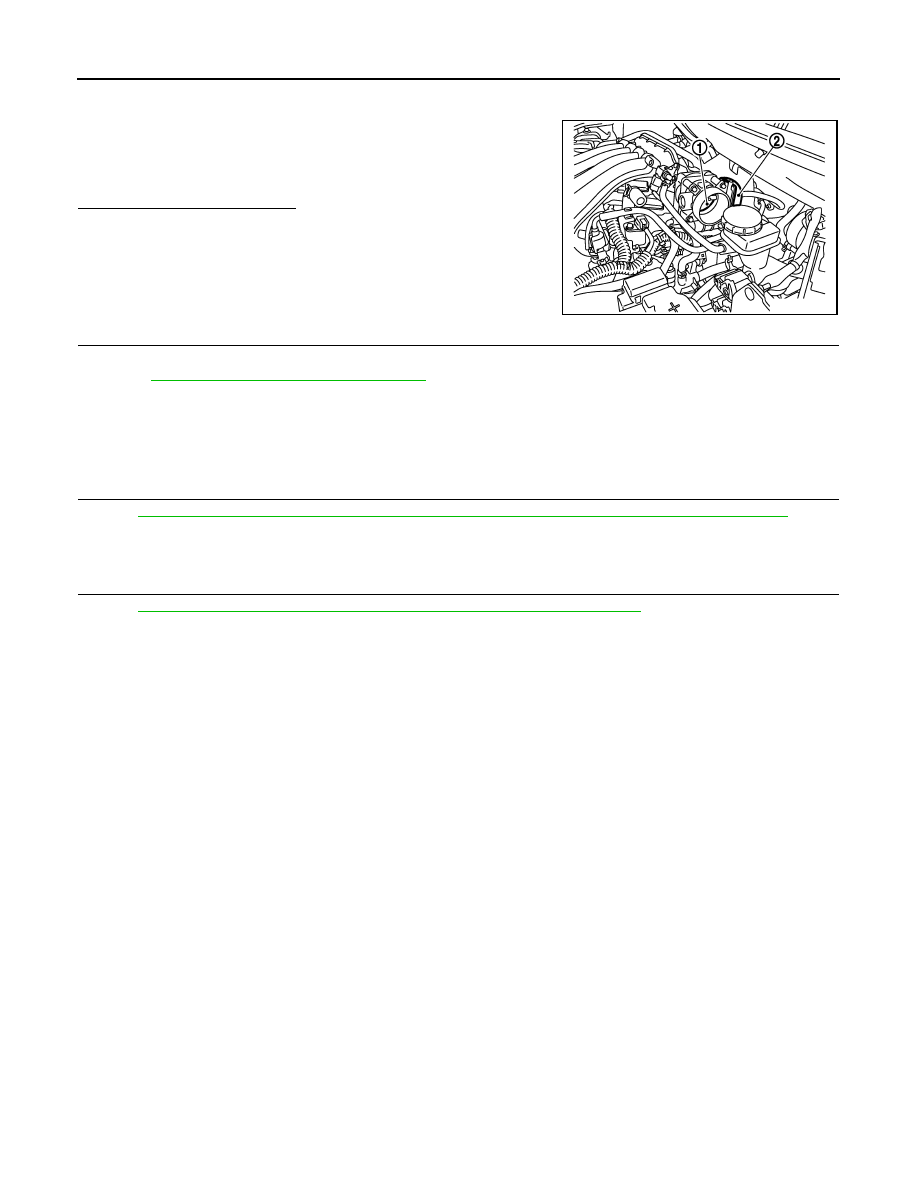

1.

Turn ignition switch OFF.

2.

Remove the intake air duct.

3.

Check if foreign matter is caught between the throttle valve (1)

and the housing.

Is the inspection result normal?

YES

>> GO TO 2.

NO

>> Remove the foreign matter and clean the electric throttle

control actuator inside.

2.

REPLACE ELECTRIC THROTTLE CONTROL ACTUATOR

1.

Replace electric throttle control actuator.

2.

Go to

EC-1117, "Special Repair Requirement"

>> INSPECTION END

Special Repair Requirement

INFOID:0000000001094189

1.

PERFORM THROTTLE VALVE CLOSED POSITION LEARNING

EC-647, "THROTTLE VALVE CLOSED POSITION LEARNING : Special Repair Requirement"

.

>> GO TO 2.

2.

PERFORM IDLE AIR VOLUME LEARNING

EC-647, "IDLE AIR VOLUME LEARNING : Special Repair Requirement"

>> END

2.

Electric throttle control actuator

JMBIA0447ZZ

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст