Nissan Qashqai (2007-2010). Manual — part 694

BRAKE BOOSTER

BR-75

< ON-VEHICLE REPAIR >

[RHD]

C

D

E

G

H

I

J

K

L

M

A

B

BR

N

O

P

• Be careful not to damage brake booster stud bolt threads. If brake booster is tilted during installa-

tion, the dash panel may damage the threads.

• Never deform or bend the brake tubes when installing the brake booster.

• Always use a new gasket between the brake booster and the spacer.

• Replace the clevis pin if it is damaged. Refer to

BR-62, "Inspection and Adjustment"

• After installation, perform the air bleeding. Refer to

BR-56, "Bleeding Brake System"

.

CAUTION:

Never reuse drained brake fluid.

Inspection and Adjustment

INFOID:0000000000938076

INSPECTION AFTER REMOVAL

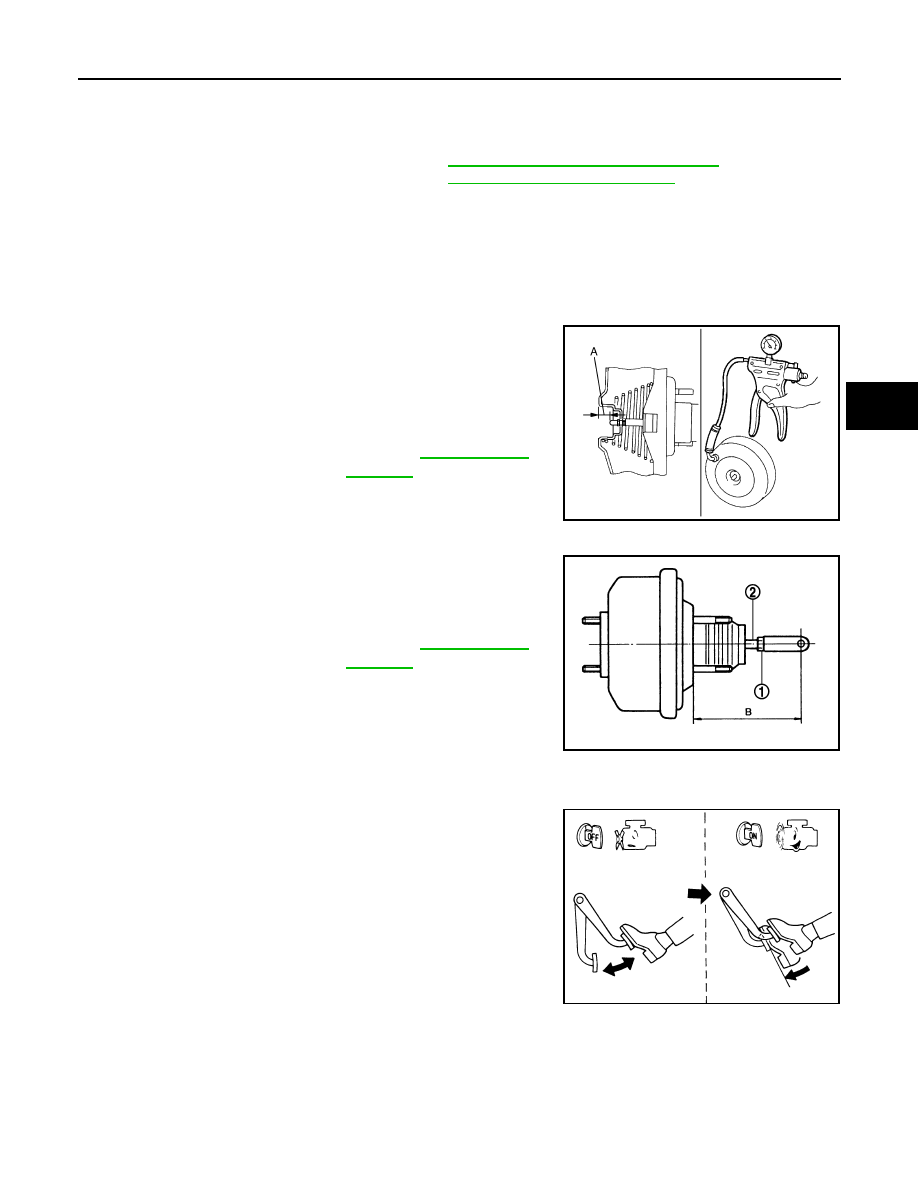

Output Rod Length Inspection

1.

With a handy vacuum pomp, apply vacuum pressure of

−

66.7

kPa (

−

500 mmHg,

−

19.70 inHg,

−

0.667 bar) to the brake

booster.

2.

Check the output rod length (A).

Input Rod Length Inspection

1.

Loosen the lock nut (1) and adjust the input rod (2) to the speci-

fied length (B).

2.

Tighten the lock nut to the specified torque.

INSPECTION AFTER INSTALLATION

Operation

Depress the brake pedal several times at 5-second intervals with the

engine stopped. Start the engine with the brake pedal fully

depressed. Check that the clearance between brake pedal and dash

lower pane decreases.

NOTE:

A slight impact with a small click may be felt on the pedal when the

brake pedal is fully depressed. This is a normal phenomenon due to

the brake system operation.

Air Tight

Standard

Output rod length (A)

: Refer to

.

JPFIA0021ZZ

Standard

Input rod length (B)

: Refer to

.

JPFIA0020ZZ

BRA0037D

BR-76

< ON-VEHICLE REPAIR >

[RHD]

BRAKE BOOSTER

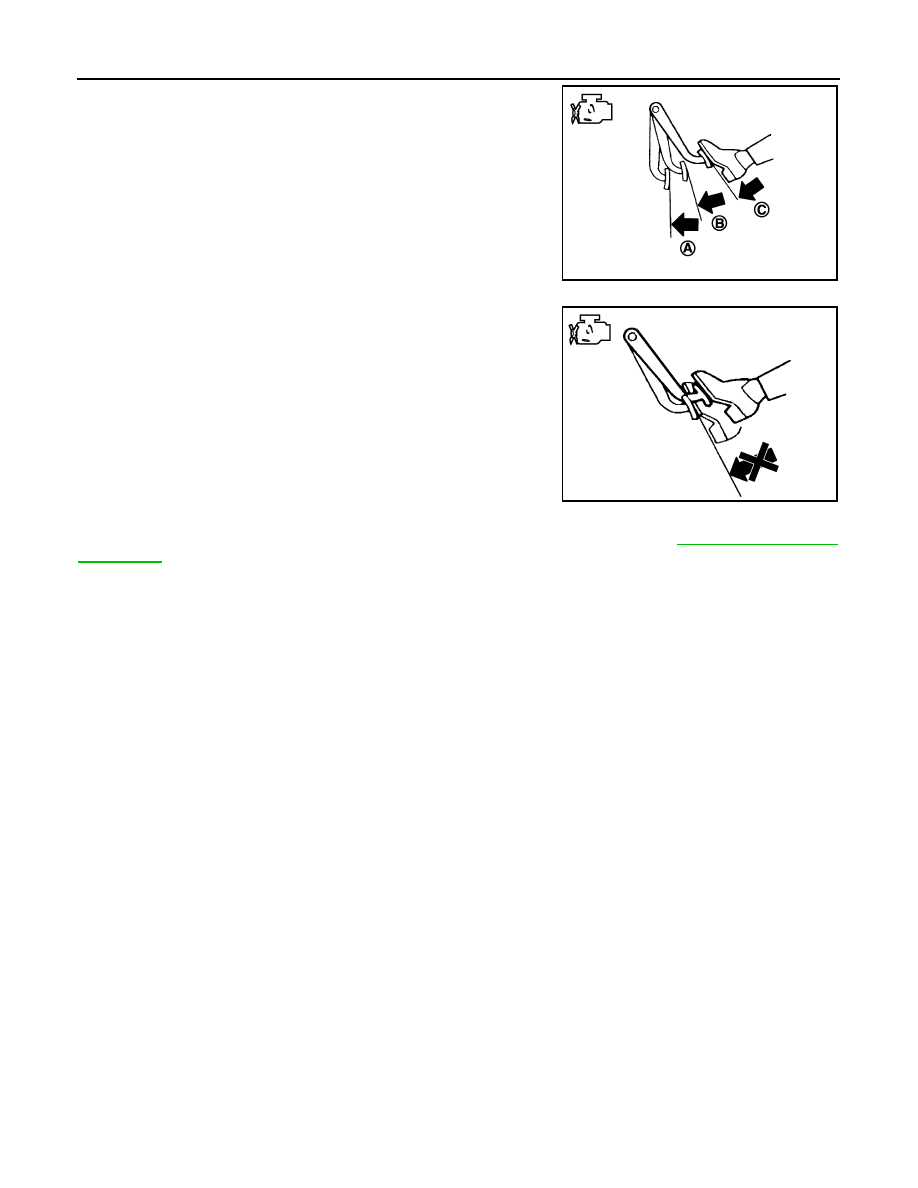

• Idle the engine for 1 minute to apply vacuum to the brake booster,

and stop the engine. Then depress the brake pedal several times

at 5-second intervals until the accumulated vacuum is released to

atmospheric pressure. Check that the clearance between brake

pedal and dash lower panel gradually increases (A

→

B

→

C) each

time the brake pedal is depressed during this operation.

• Depress the brake pedal with the engine running. Then stop the

engine while holding down the brake pedal. Check that the brake

pedal stroke does not change after holding down the brake pedal

for 30 seconds or more.

NOTE:

A slight impact with a small click may be felt on the pedal when the

brake pedal is fully depressed. This is a normal phenomenon due

to the brake system operation.

ADJUSTMENT AFTER INSTALLTION

Perform the brake pedal adjustment after installing the brake pedal assembly. Refer to

.

JPFIA0043ZZ

JPFIA0044ZZ

VACUUM LINES

BR-77

< ON-VEHICLE REPAIR >

[RHD]

C

D

E

G

H

I

J

K

L

M

A

B

BR

N

O

P

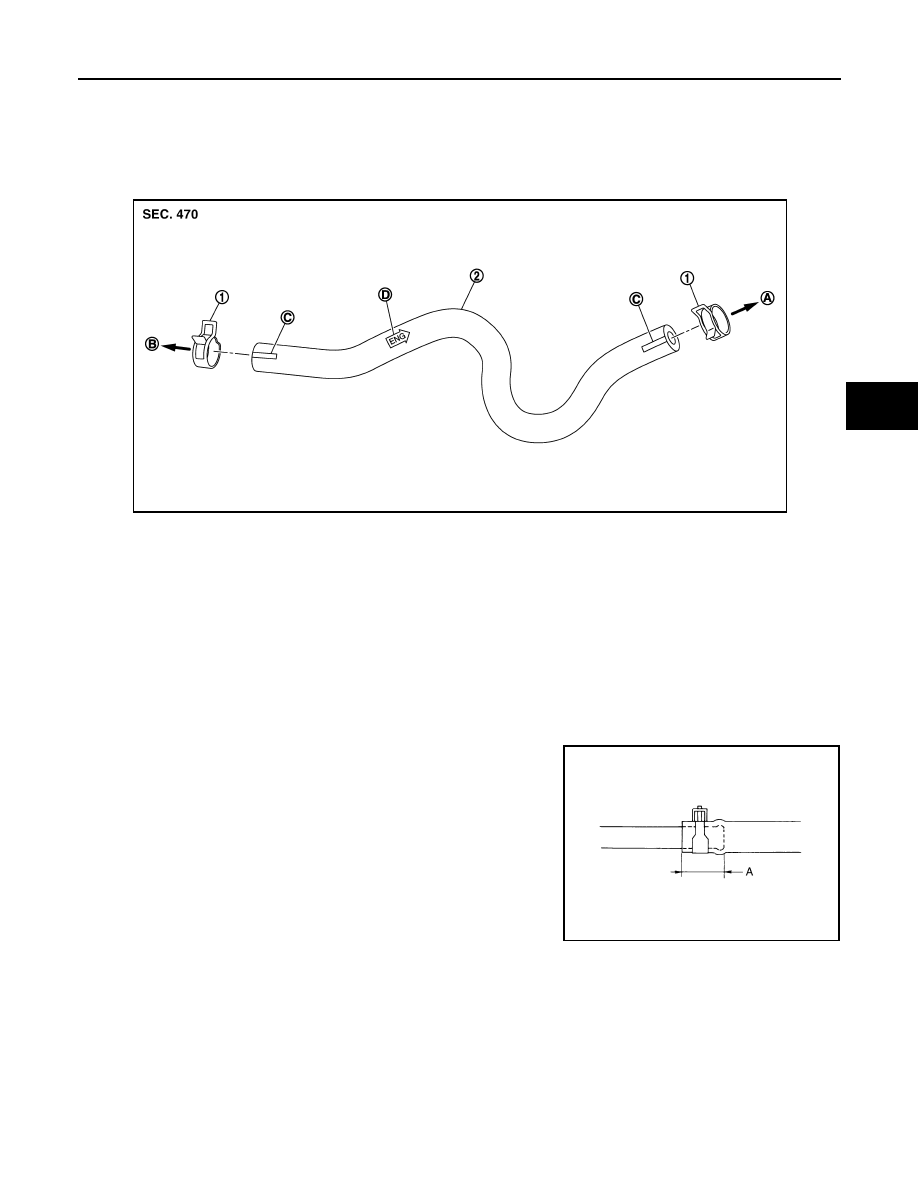

VACUUM LINES

HR16DE/MR20DE MODELS

HR16DE/MR20DE MODELS : Exploded View

INFOID:0000000000938077

HR16DE/MR20DE MODELS : Removal and Installation

INFOID:0000000000938078

REMOVAL

Remove the vacuum hose.

INSTALLATION

Install the vacuum hose.

CAUTION:

• Because vacuum hose contains a check valve, it must be

installed in the correct position. Refer to the stamp to confirm

correct installation. Brake booster will not operate normally if

the hose is installed in the wrong direction.

• Insert vacuum hose at least 24 mm (0.94 in) (A).

• Never use lubricating oil during assembly.

• Face the marking side up when assembling of vacuum hose.

HR16DE/MR20DE MODELS : Inspection

INFOID:0000000000938079

INSPECTION AFTER REMOVAL

Appearance

Check for correct assembly, damage and deterioration.

Check Valve Airtightness

1.

Clamp

2.

Vacuum hose (built in check valve)

A.

To intake manifold

B.

To brake booster

C.

Paint mark

D.

Stamp indicating engine direction

JPFIA0087ZZ

JPFIA0023ZZ

BR-78

< ON-VEHICLE REPAIR >

[RHD]

VACUUM LINES

• Use a handy vacuum pump (A) to check.

• Replace vacuum hose assembly if vacuum hose and check valve

are malfunctioning.

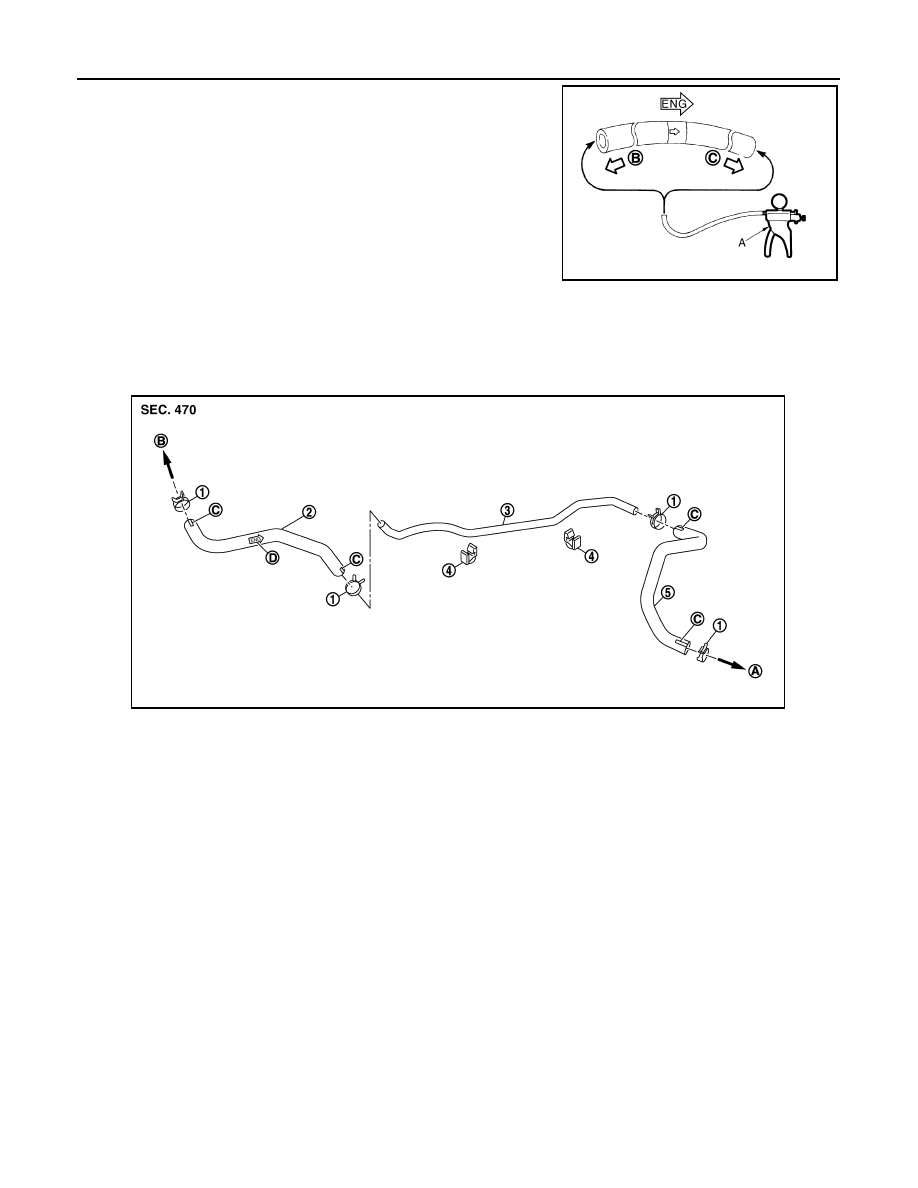

K9K MODELS

K9K MODELS : Exploded View

INFOID:0000000000938080

K9K MODELS : Removal and Installation

INFOID:0000000000938081

REMOVAL

Remove the vacuum hose and tube.

INSTALLATION

Install the vacuum hose and tube.

CAUTION:

When connected to the brake booster side (B):

Vacuum should decrease within 1.3 kPa (10 mm-

Hg, 0.39 inHg, 0.013 bar) for 15 seconds under a

vacuum of

−

66.7 kPa (

−

500 mmHg,

−

19.70 inHg,

−

0.667 bar).

When connected to the engine side (C):

Vacuum should not exist.

JPFIA0024ZZ

1.

Clamp

2.

Vacuum hose (built in check valve)

3.

vacuum tube

4.

Clip

5.

Vacuum hose

A.

To vacuum pomp

B.

To brake booster

C.

Paint mark

D.

Stamp indicating engine direction

JPFIA0088ZZ

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст