Nissan Qashqai (2007-2010). Manual — part 1187

PRE-INSPECTION FOR DIAGNOSTIC

DLK-827

< ON-VEHICLE MAINTENANCE >

[WITHOUT I-KEY, WITH SUPER LOCK]

C

D

E

F

G

H

I

J

L

M

A

B

DLK

N

O

P

ON-VEHICLE MAINTENANCE

PRE-INSPECTION FOR DIAGNOSTIC

Basic Inspection

INFOID:0000000001090935

BASIC INSPECTION

1.

CHECK DOOR LOCK AND UNLOCK SWITCH OPERATION

Check door lock and unlock operation by operating door lock and unlock switch.

Is the inspection result normal?

YES

>> GO TO 2.

NO

>> Refer to

DLK-812, "DOOR LOCK AND UNLOCK SWITCH : Symptom Table"

.

2.

CHECK KEYFOB OPERATION

Check door lock and unlock operation by operationg lock and unlock button of keyfob.

Is the inspection result normal?

YES

>> GO TO 3.

NO

>> Refer to

DLK-812, "KEYFOB : Symptom Table"

.

3.

CHECK AUTO DOOR LOCK OPERATION

Check auto door lock operation. Refer to

DLK-723, "AUTO DOOR LOCK : System Description"

Is the inspection result normal?

YES

>> GO TO 4.

NO

>> Refer to

DLK-813, "AUTO DOOR LOCK : Symptom Table"

4.

CHECK VEHICLE SPEED SENSING AUTO DOOR LOCK OPERATION

Check vehicle speed sensing auto door lock. Refer to

DLK-725, "VEHICLE SPEED SENSING AUTO DOOR

Is the inspection result normal?

YES

>> GO TO 5.

NO

>> Refer to

DLK-813, "VEHICLE SPEED SENSING AUTO DOOR LOCK : Symptom Table"

5.

CHECK BACK DOOR OPENER SWITCH OPERATION

Check back door opener operation by operating back door opener switch.

Is the inspection result normal?

YES

>> GO TO 6.

NO

>> Refer to

DLK-815, "BACK DOOR OPENER SWITCH : Symptom Table"

6.

CHECK HAZARD REMINDER FUNCTION

Check hazard reminder function by operating the following switches.

• Lock and unlock button of keyfob.

Is the inspection result normal?

YES

>> GO TO 7.

NO

>> Refer to

DLK-817, "HAZARD WARNING LAMP : Symptom Table"

7.

CHECK WARNING FUNCTION

Check that warning function operate properly. Refer to

.

Is the inspection result normal?

YES

>> GO TO 8.

NO

>> Refer to

DLK-817, "HAZARD WARNING LAMP : Symptom Table"

8.

CHECK OUT

CHECK OUT.

>> INSPECTION END

DLK-828

< ON-VEHICLE REPAIR >

[WITHOUT I-KEY, WITH SUPER LOCK]

HOOD

ON-VEHICLE REPAIR

HOOD

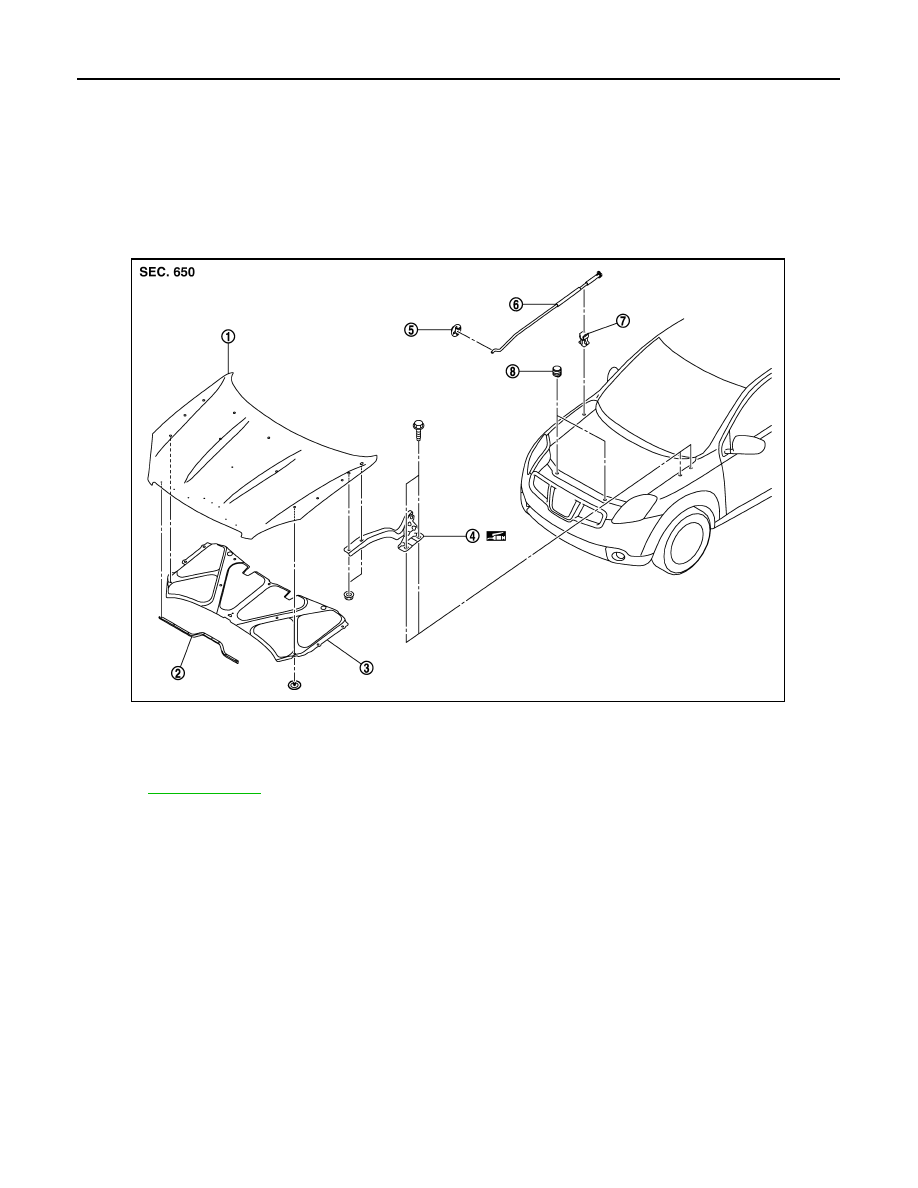

HOOD ASSEMBLY

HOOD ASSEMBLY : Exploded View

INFOID:0000000001098695

REMOVAL

ADJUSTMENT

1.

Hood assembly

2.

Hood sealing rubber

3.

Hood insulator

4.

Hood hinge

5.

Grommet

6.

Hood support rod

7.

Clamp

8.

Hood bumper rubber

Refer to

for symbols in the figure.

JMKIA0175ZZ

HOOD

DLK-829

< ON-VEHICLE REPAIR >

[WITHOUT I-KEY, WITH SUPER LOCK]

C

D

E

F

G

H

I

J

L

M

A

B

DLK

N

O

P

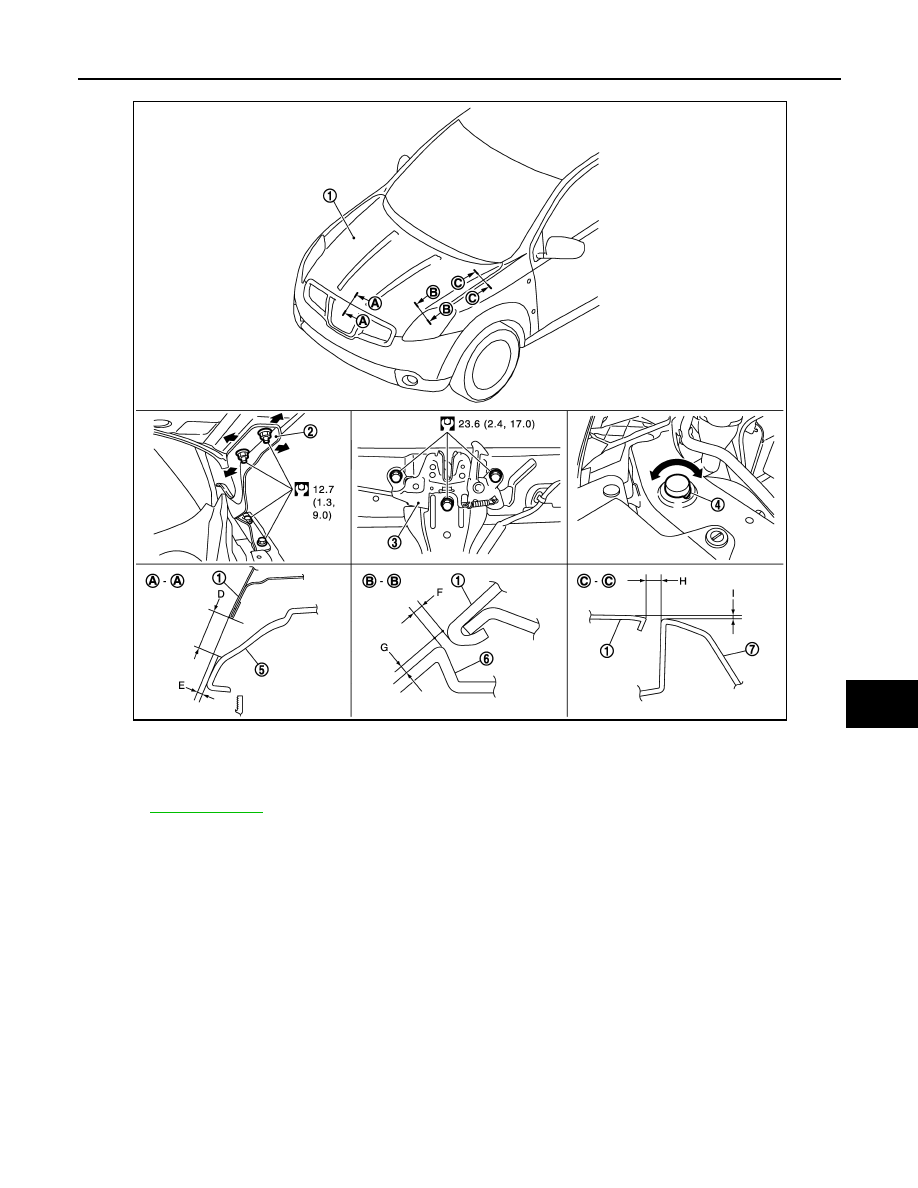

HOOD ASSEMBLY : Removal and Installation

INFOID:0000000001098696

REMOVAL

1.

Support the hood lock assembly with the proper material to prevent it from falling.

WARNING:

Bodily injury may occur if no supporting rod is holding the hood open when removing the hood

stay.

2.

Remove the hood hinge mounting nuts on the hood to remove the hood assembly.

CAUTION:

Perform work with 2 workers, because of its heavy weight.

3.

Remove the following parts after removing the hood assembly.

• Hood insulator

• Hood sealing rubber

INSTALLATION

Install in the reverse order of removal.

CAUTION:

1.

Hood assembly

2.

Hood hinge

3.

Hood lock assembly

4.

Hood bumper rubber

5.

Front grille

6.

Front combination lamp

7.

Front fender

Refer to

JMKIA0185GB

DLK-830

< ON-VEHICLE REPAIR >

[WITHOUT I-KEY, WITH SUPER LOCK]

HOOD

• Perform work with 2 workers, because of its heavy weight.

• Before installing the hood hinge, apply anticorrosive agent onto the mounting surface of the vehicle

body.

• After installing, perform hood fitting adjustment. Refer to

DLK-830, "HOOD ASSEMBLY : Adjust-

HOOD ASSEMBLY : Adjustment

INFOID:0000000001098697

1.

Check the clearance and the surface height between the hood and each part by visualy and touching.

(Fitting standard dimension in the table below should be satisfied.)

2.

In case any parts are out of specification, adjust them according to the procedures shown below.

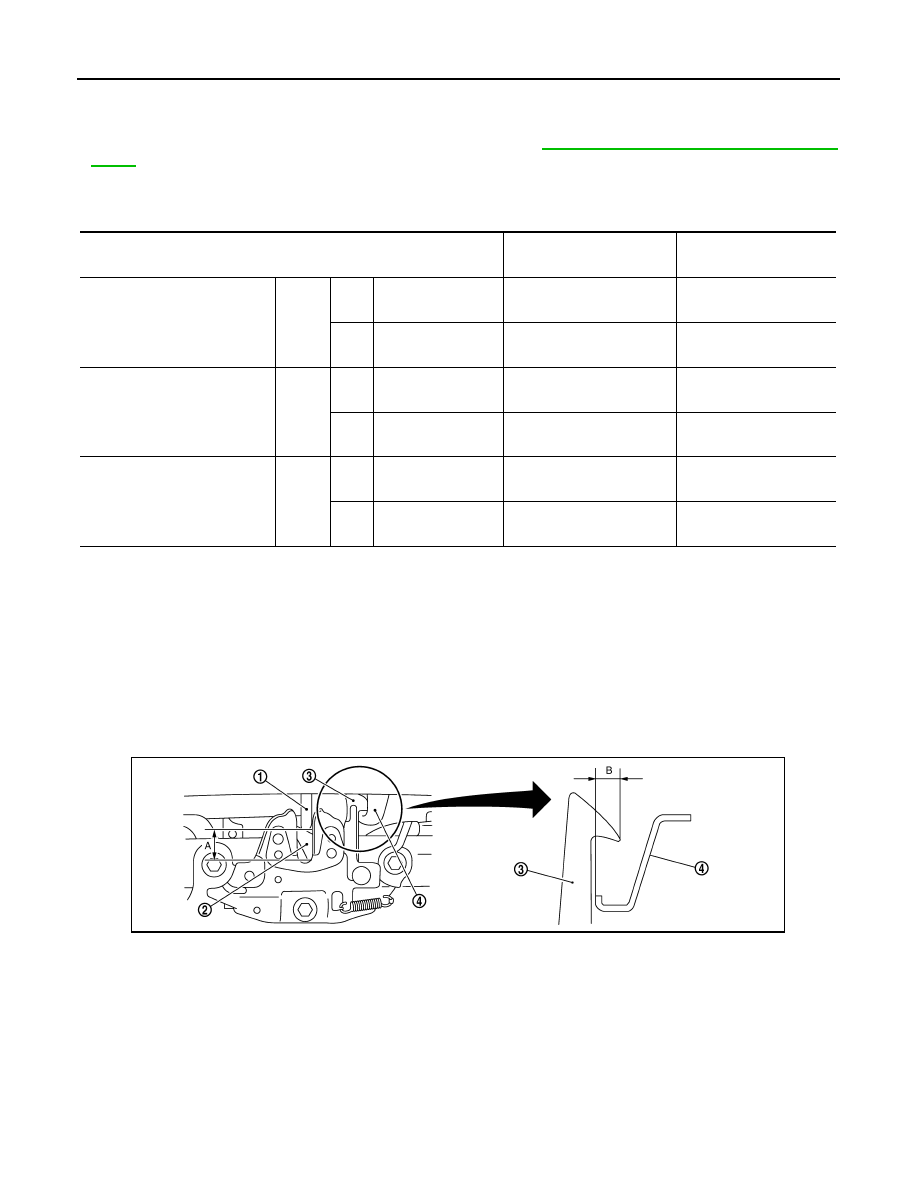

3.

Remove the hood lock and adjust the height by rotating the bumper rubber until the hood becomes 1 to1.5

mm (0.04 to 0.059 in) lower than the fender.

4.

Temporarily tighten the hood lock, and position by engaging it with the hood striker. Check the lock and

striker for looseness and adjust the clearance and evenness with the striker to satisfy the specification.

5.

Adjust A and B shown in the figure to the following value with hood's own weight by dropping it from

approximately. 200 mm (7.87 in) height or by pressing the hood lightly [approximately. 29 N (3 kg)].

6.

After adjustment tighten lock bolts to the specified torque.

HOOD HINGE

Portion

Standard

Right/left

Clearance (MAX)

Hood – Front bumper

A – A

D

Clearance

5.2 – 9.2 mm

(0.205 – 0.362 in)

2.0 mm (0.079 in)

E

Surface height

- 0.2 – 3.8 mm

(- 0.008 – 0.150 in)

2.0 mm (0.079 in)

Hood –

Front combination lamp

B – B

F

Clearance

3.7 – 7.7 mm

(0.140 – 0.303 in)

2.0 mm (0.079 in)

G

Surface height

- 2.3 – 2.3 mm

(- 0.091 – 0.091 in)

2.3 mm (0.091 in)

Hood – Front fender

C – C

H

Clearance

3.9 – 5.9 mm

(0.154 – 0.232 in)

1.5 mm (0.059 in)

I

Surface height

- 1.0 – 1.0 mm

(- 0.039 – 0.039 in)

1.5 mm (0.059 in)

1.

Hood striker

2.

Primary latch

3.

Secondary striker

4.

Secondary latch

A

: 20.0 mm (0.787 in)

B

: 6.8 mm (0.268 in)

PIIB5794E

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст