Nissan Qashqai (2007-2010). Manual — part 61

EM-192

< ON-VEHICLE REPAIR >

[MR20DE]

CYLINDER HEAD

• If the calculated value exceeds the limit, replace valve and/or valve guide. When valve guide must be

EM-187, "Disassembly and Assembly"

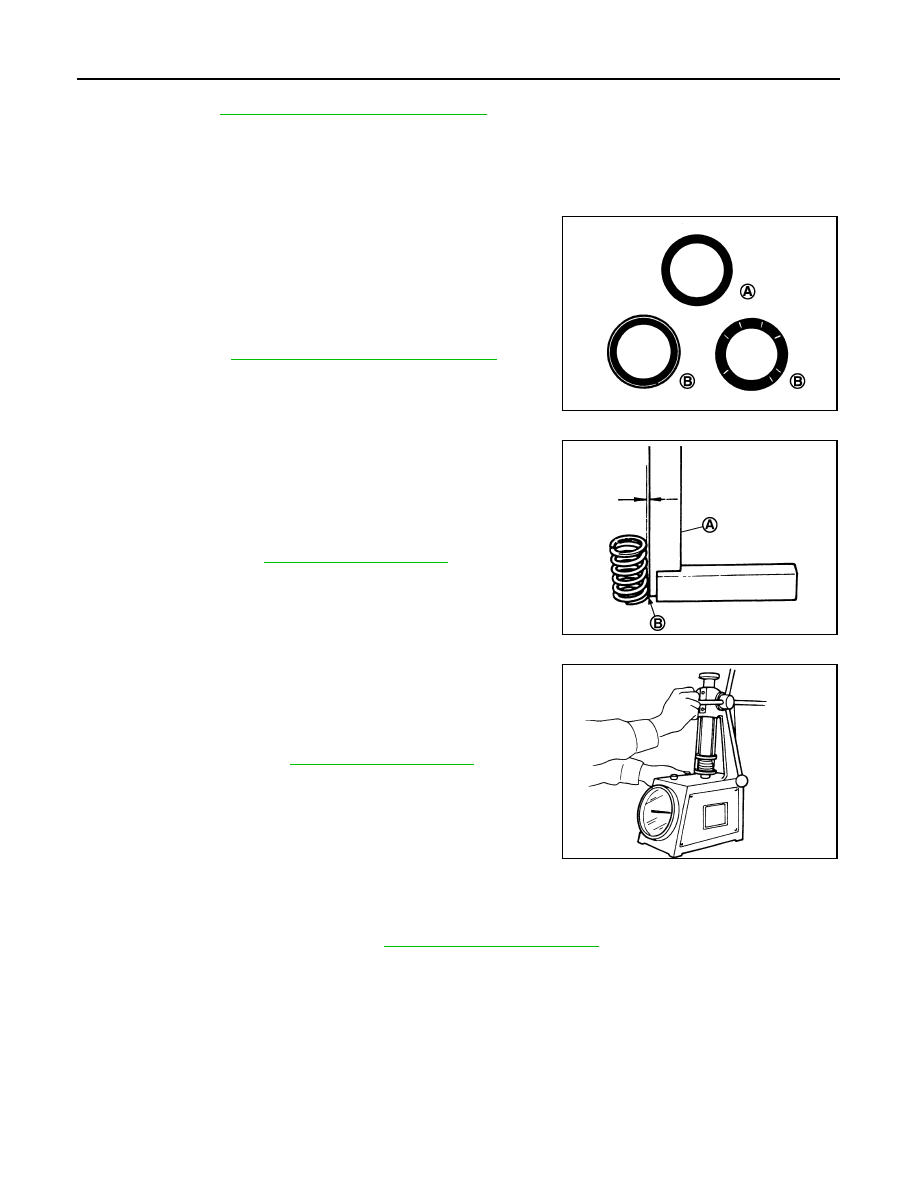

VALVE SEAT CONTACT

• After confirming that the dimensions of valve guides and valves are within the specifications, perform this

procedure.

• Apply prussian blue (or white lead) onto contacting surface of valve seat to check the condition of the valve

contact on the surface.

• Check if the contact area band is continuous all around the circum-

ference.

• If not, grind to adjust valve fitting and check again. If the contacting

surface still has “NG” conditions even after the re-check, replace

valve seat. Refer to

EM-187, "Disassembly and Assembly"

.

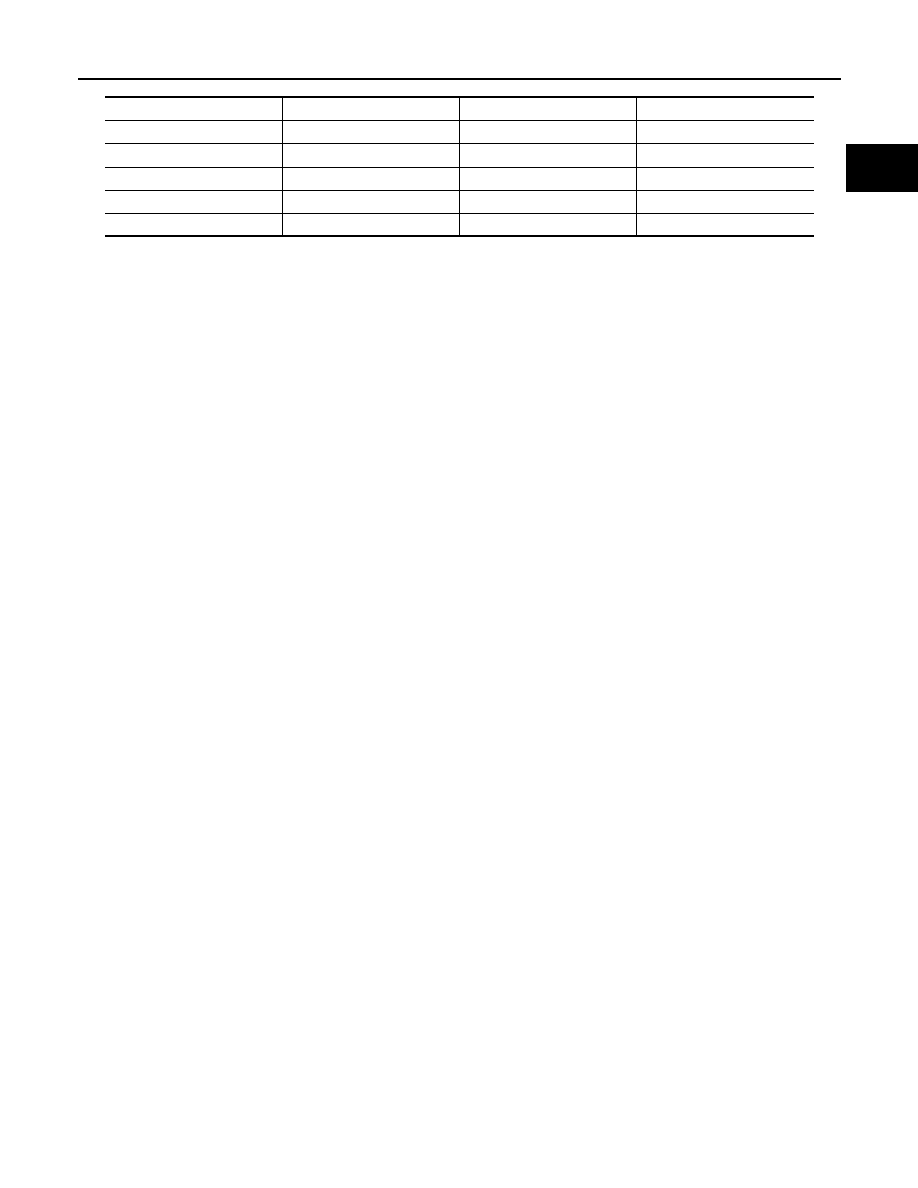

VALVE SPRING SQUARENESS

• Set a try square (A) along the side of valve spring and rotate

spring. Measure the maximum clearance between the top of spring

and try square.

• If it exceeds the limit, replace valve spring.

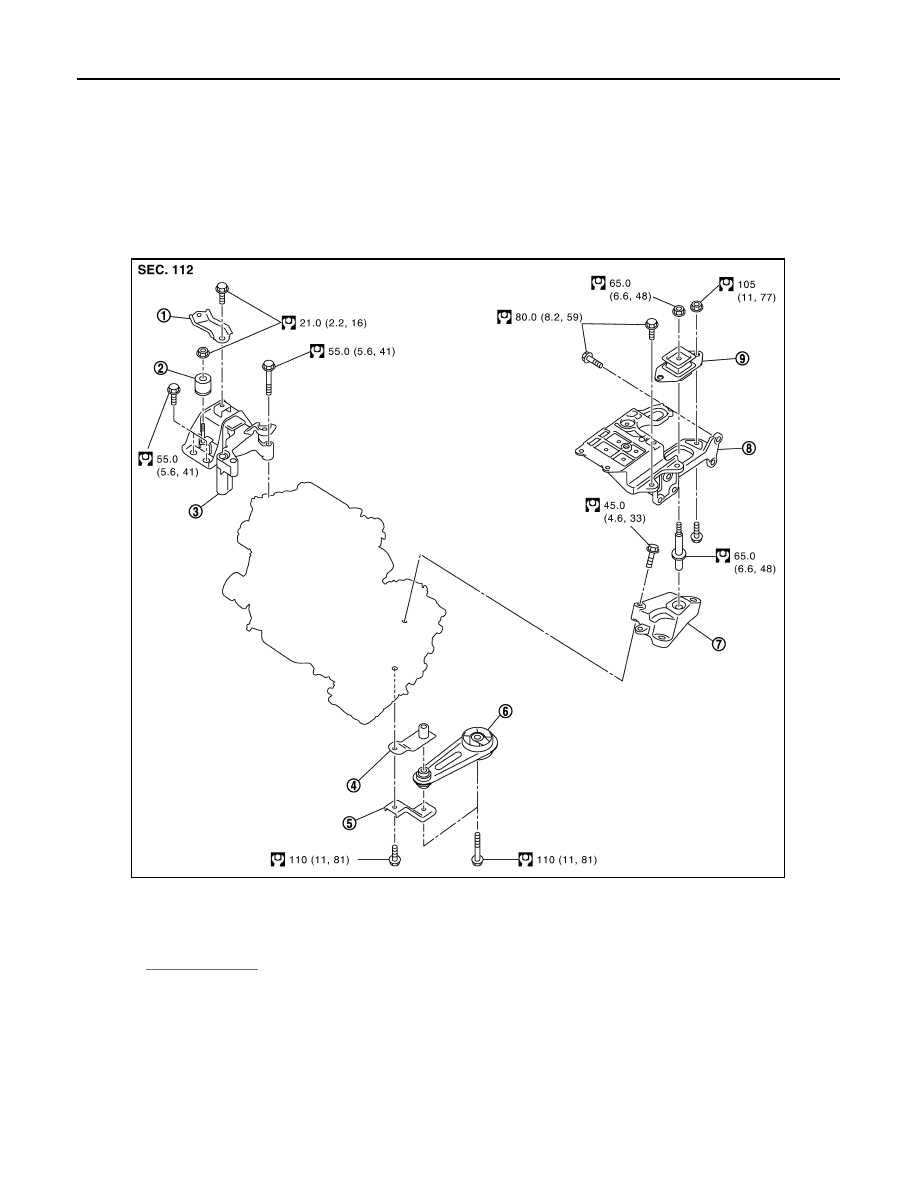

VALVE SPRING DIMENSIONS AND VALVE SPRING PRESSURE LOAD

• Check valve spring pressure with valve spring seat installed at the

specified spring height.

CAUTION:

Never remove valve spring seat from valve spring.

• If the installation load or load with valve open is out of the stan-

dard, replace valve spring (with valve spring seat).

INSPECTION AFTER INSTALLATION

Inspection for Leaks

• Before starting engine, check oil/fluid levels including engine coolant and engine oil. If less than required

quantity, fill to the specified level. Refer to

MA-21, "Fluids and Lubricants"

.

• Use procedure below to check for fuel leakage.

- Turn ignition switch “ON” (with engine stopped). With fuel pressure applied to fuel piping, check for fuel leak-

age at connection points.

- Start engine. With engine speed increased, check again for fuel leakage at connection points.

• Run engine to check for unusual noise and vibration.

• Warm up engine thoroughly to make sure there is no leakage of fuel, exhaust gases, or any oil/fluids includ-

ing engine oil and engine coolant.

• Bleed air from lines and hoses of applicable lines, such as in cooling system.

• After cooling down engine, again check oil/fluid levels including engine oil and engine coolant. Refill to the

specified level, if necessary.

A

: OK

B

: NG

JPBIA0187ZZ

B

: Contact

Limit

: Refer to

PBIC3219J

Standard

: Refer to

SEM113

CYLINDER HEAD

EM-193

< ON-VEHICLE REPAIR >

[MR20DE]

C

D

E

F

G

H

I

J

K

L

M

A

EM

N

P

O

Summary of the inspection items:

* Transmission/transaxle/CVT fluid, power steering fluid, brake fluid, etc.

Item

Before starting engine

Engine running

After engine stopped

Engine coolant

Level

Leakage

Level

Engine oil

Level

Leakage

Level

Other oils and fluid*

Level

Leakage

Level

Fuel

Leakage

Leakage

Leakage

Exhaust gases

—

Leakage

—

EM-194

< REMOVAL AND INSTALLATION >

[MR20DE]

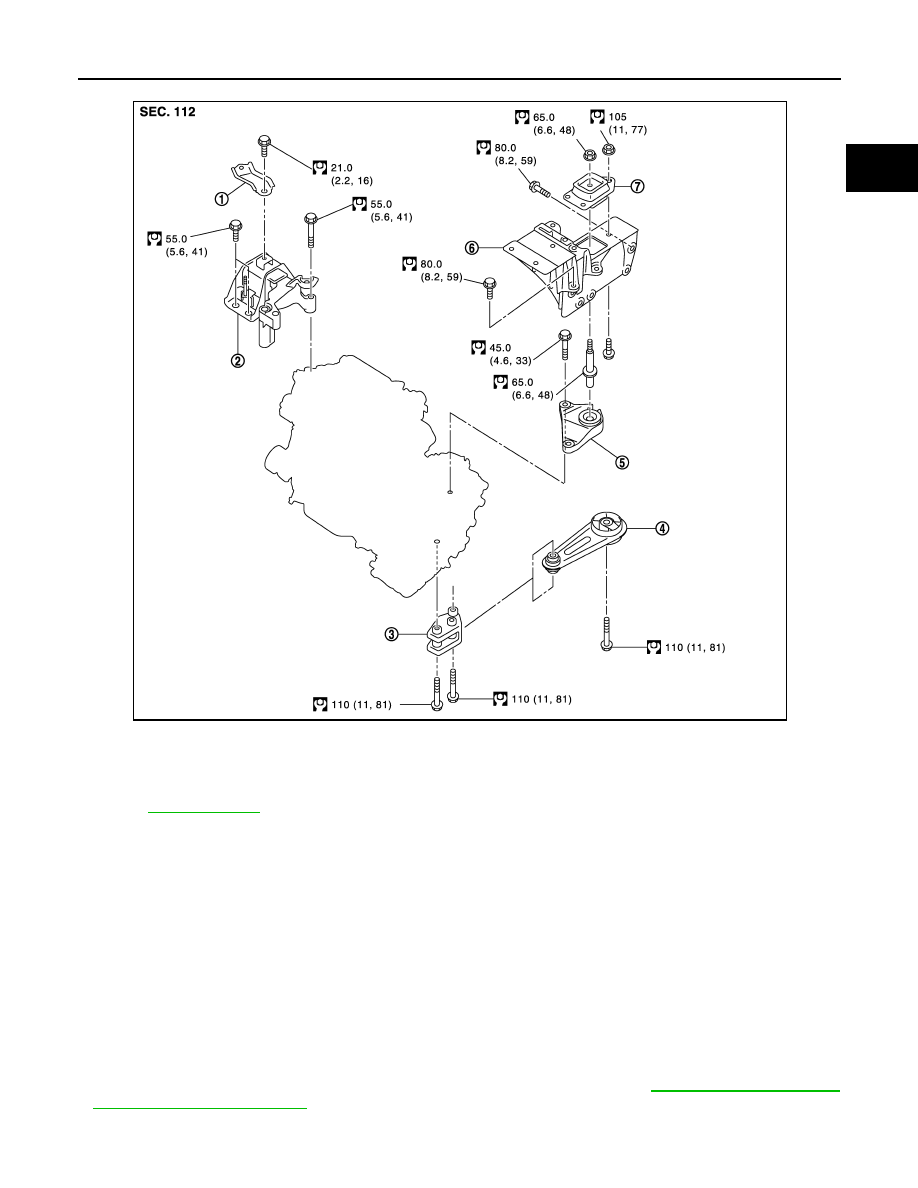

ENGINE ASSEMBLY

REMOVAL AND INSTALLATION

ENGINE ASSEMBLY

M/T

M/T : Exploded View

INFOID:0000000000893959

2WD models

4WD models

1.

Engine mounting stay

2.

Dynamic damper

3.

Engine mounting insulator (RH)

4.

Rear engine mounting bracket

5.

Rear engine mounting bracket

6.

Rear torque rod

7.

Engine mounting bracket (LH)

8.

Engine mounting bracket (LH)

9.

Engine mounting insulator (LH)

Refer to

for symbols in the figure.

JPBIA0392GB

ENGINE ASSEMBLY

EM-195

< REMOVAL AND INSTALLATION >

[MR20DE]

C

D

E

F

G

H

I

J

K

L

M

A

EM

N

P

O

M/T : Removal and Installation

INFOID:0000000000893960

WARNING:

• Situate the vehicle on a flat and solid surface.

• Place chocks at front and back of rear wheels.

• Attach proper slingers and bolts described in PARTS CATALOG if engine slingers are not equipped.

CAUTION:

• Always be careful to work safely, avoid forceful or uninstructed operations.

• Never start working until exhaust system and coolant are cool enough.

• If items or work required are not covered by the engine section, refer to the applicable sections.

• Always use the support point specified for lifting.

• Use either 2-pole lift type or separate type lift as best you can. If board-on type is used for unavoid-

able reasons, support at the rear axle jacking point with a transmission jack or similar tool before

starting work, in preparation for the backward shift of center of gravity.

• For supporting points for lifting and jacking point at rear axle, refer to

REMOVAL

1.

Engine mounting stay

2.

Engine mounting insulator (RH)

3.

Rear engine mounting bracket

4.

Rear torque rod

5.

Engine mounting bracket (LH)

6.

Engine mounting bracket (LH)

7.

Engine mounting insulator (LH)

Refer to

for symbols in the figure.

JPBIA0393GB

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст