Nissan Qashqai (2007-2010). Manual — part 9

TOW TRUCK TOWING

GI-35

< PRECAUTION >

C

D

E

F

G

H

I

J

K

L

M

B

GI

N

O

P

TOW TRUCK TOWING

Tow Truck Towing

INFOID:0000000001095978

CAUTION:

• All applicable local laws regarding the towing operation must be obeyed.

• It is necessary to use proper towing equipment to avoid possible damage to the vehicle during tow-

ing operation. Towing is in accordance with Towing Procedure Manual at dealer.

• Always attach safety chains before towing.

• When towing, make sure that the transmission, steering system and powertrain are in good order. If

any unit is damaged, dollies must be used.

• Never tow an automatic transmission model from the rear (that is backward) with four wheels on the

ground. This may cause serious and expensive damage to the transmission.

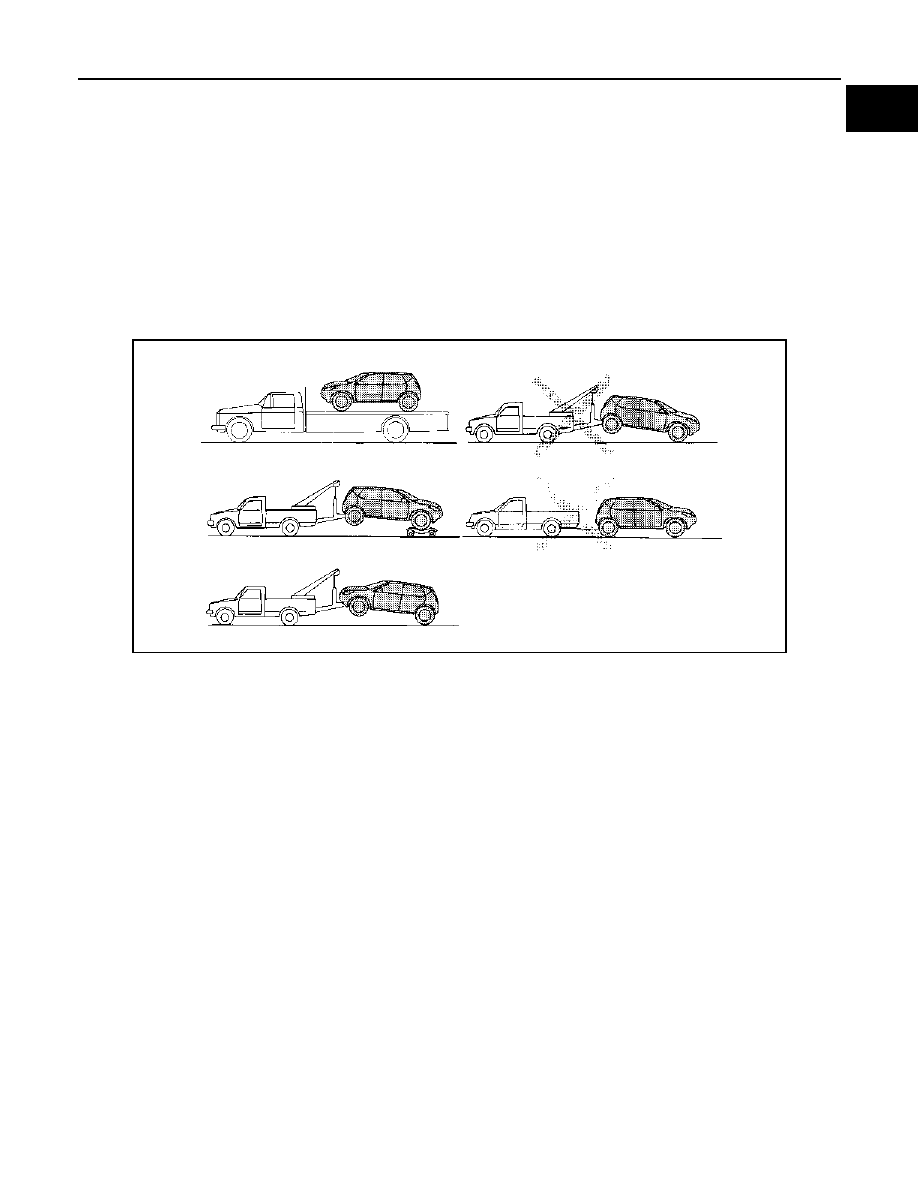

2WD MODELS

NISSAN recommends that vehicle be towed with the driving (front) wheels off the ground or that a dolly be

used as illustrated.

CAUTION:

• Never tow CVT models with the front wheels on the ground or four wheels on the ground (forward or

backward), as this may cause serious and expensive damage to the transmission.

If it is necessary to tow the vehicle with the rear wheels raised, always use towing dollies under the

front wheels.

• When towing CVT models with the front wheels on towing dollies:

- Turn the ignition key to the OFF position, and secure the steering wheel in a straight ahead position

with a rope or similar device.Never secure the steering wheel by turning the ignition key to the LOCK

position. This may damage the steering lock mechanism.

- Move the selector lever to the N (Neutral) position.

• When towing two wheel drive CVT model with the rear wheels on the ground (if you do not use tow-

ing dollies): Always release the parking brake.

JMAIA0020ZZ

GI-36

< PRECAUTION >

TOW TRUCK TOWING

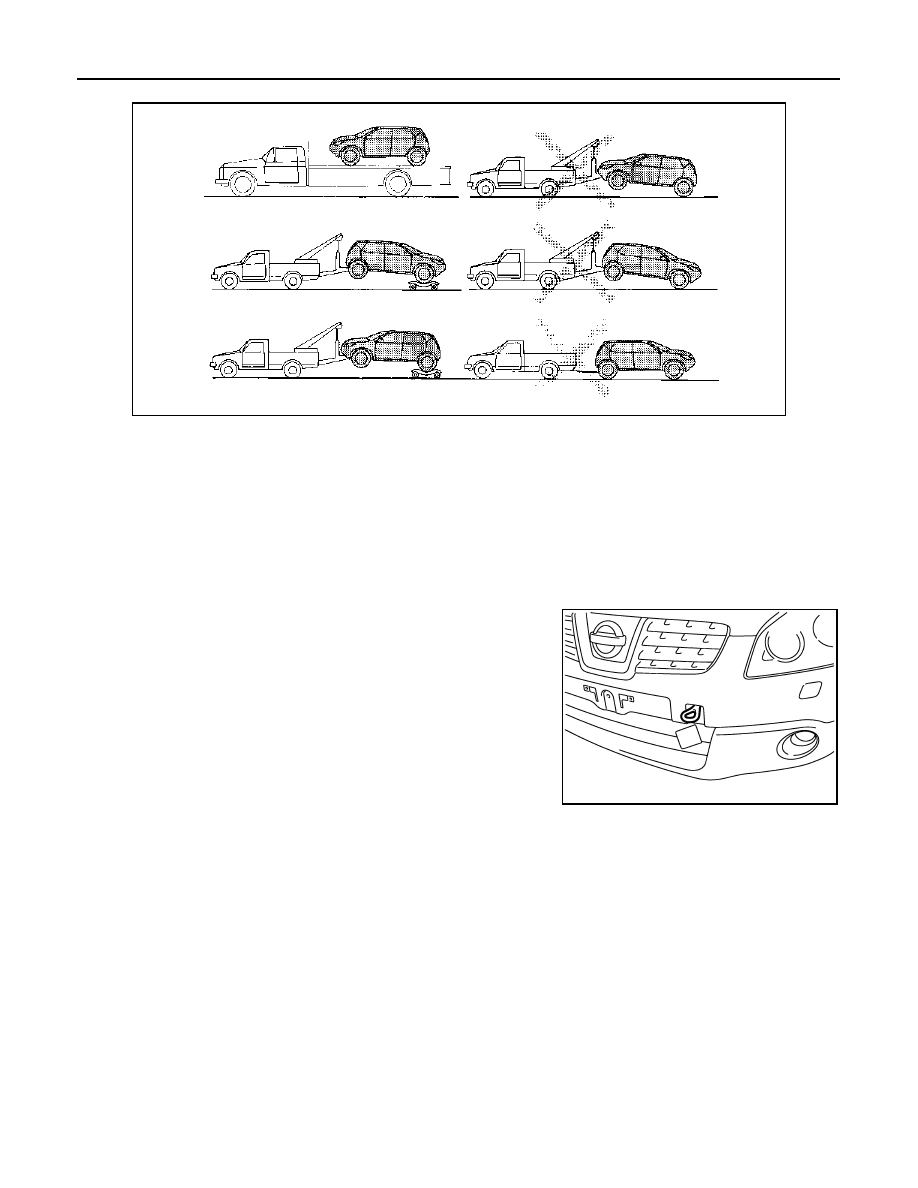

AWD MODELS

NISSAN recommends that a dolly be used as illustrated when towing AWD models.

CAUTION:

Never tow AWD models with any of the wheels on the ground as this may cause serious and expen-

sive damage to the drive train.

Vehicle Recovery (Freeing a Stuck Vehicle)

INFOID:0000000001095979

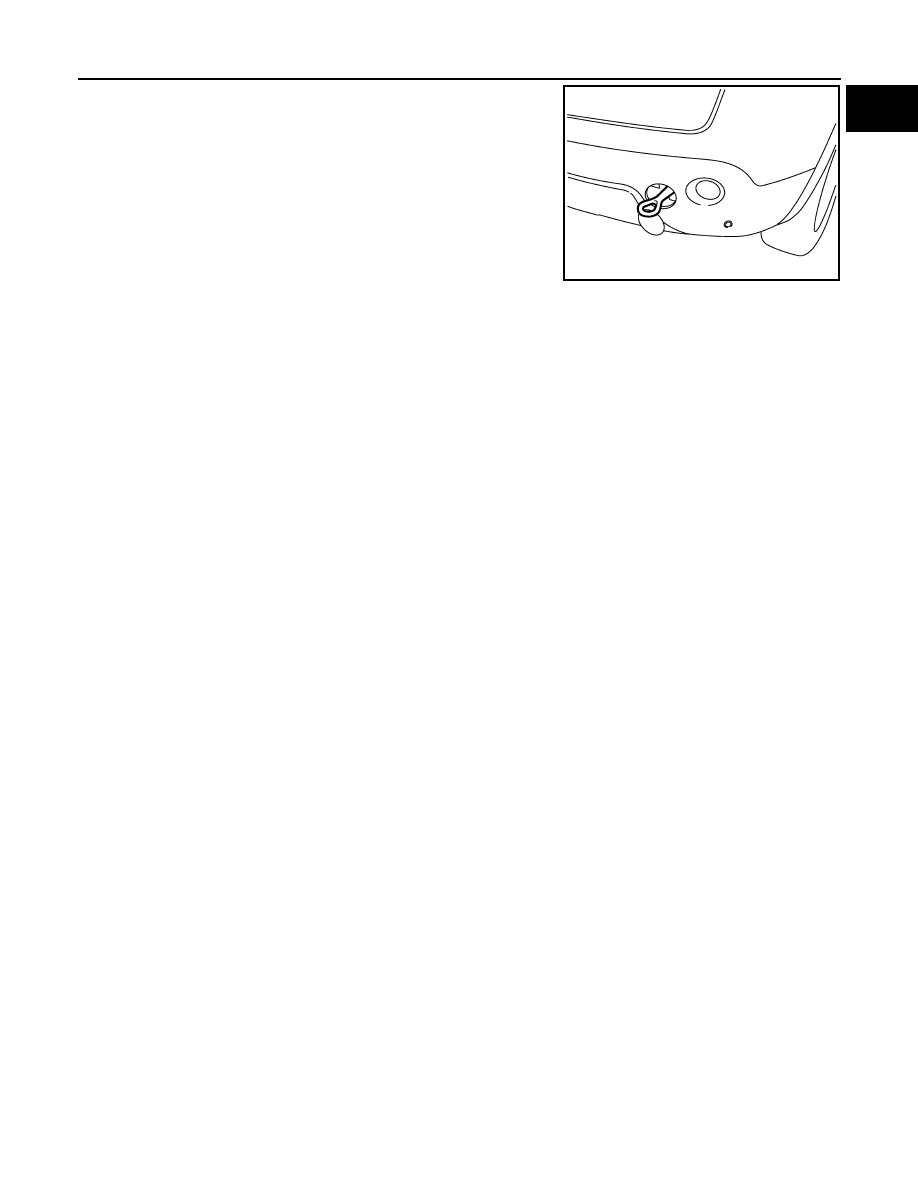

FRONT

1.

Remove the hook cover from the bumper using a remover tool.

2.

Securely install the vehicle recovery hook stored with jacking

tools.

Make sure that the hook is properly secured in the stored place after

use.

WARNING:

• Stand clear of a stuck vehicle.

• Do not spin your tires at high speed. This could cause them to

explode and result in serious injury. Parts of your vehicle

could also overheat and be damaged.

CAUTION:

• Tow chains or cables must be attached only to the vehicle

recovery hooks or main structural members of the vehicle.

Otherwise, the vehicle body will be damaged.

• Do not use the vehicle tie downs to free a vehicle stuck in sand, snow, mud, etc. Never tow the vehi-

cle using the vehicle tie downs or recovery hooks.

• Always pull the cable straight out from the front of the vehicle. Never pull on the hook at an angle.

• Pulling devices should be routed so they do not touch any part of the suspension, steering, brake or

cooling systems.

• Pulling devices such as ropes or canvas straps are not recommended for use in vehicle towing or

recovery.

REAR

WARNING:

JMAIA0021ZZ

JMAIA0012ZZ

TOW TRUCK TOWING

GI-37

< PRECAUTION >

C

D

E

F

G

H

I

J

K

L

M

B

GI

N

O

P

• Rear hook is not available.

JMAIA0013ZZ

GI-38

< BASIC INSPECTION >

SERVICE INFORMATION FOR ELECTRICAL INCIDENT

BASIC INSPECTION

SERVICE INFORMATION FOR ELECTRICAL INCIDENT

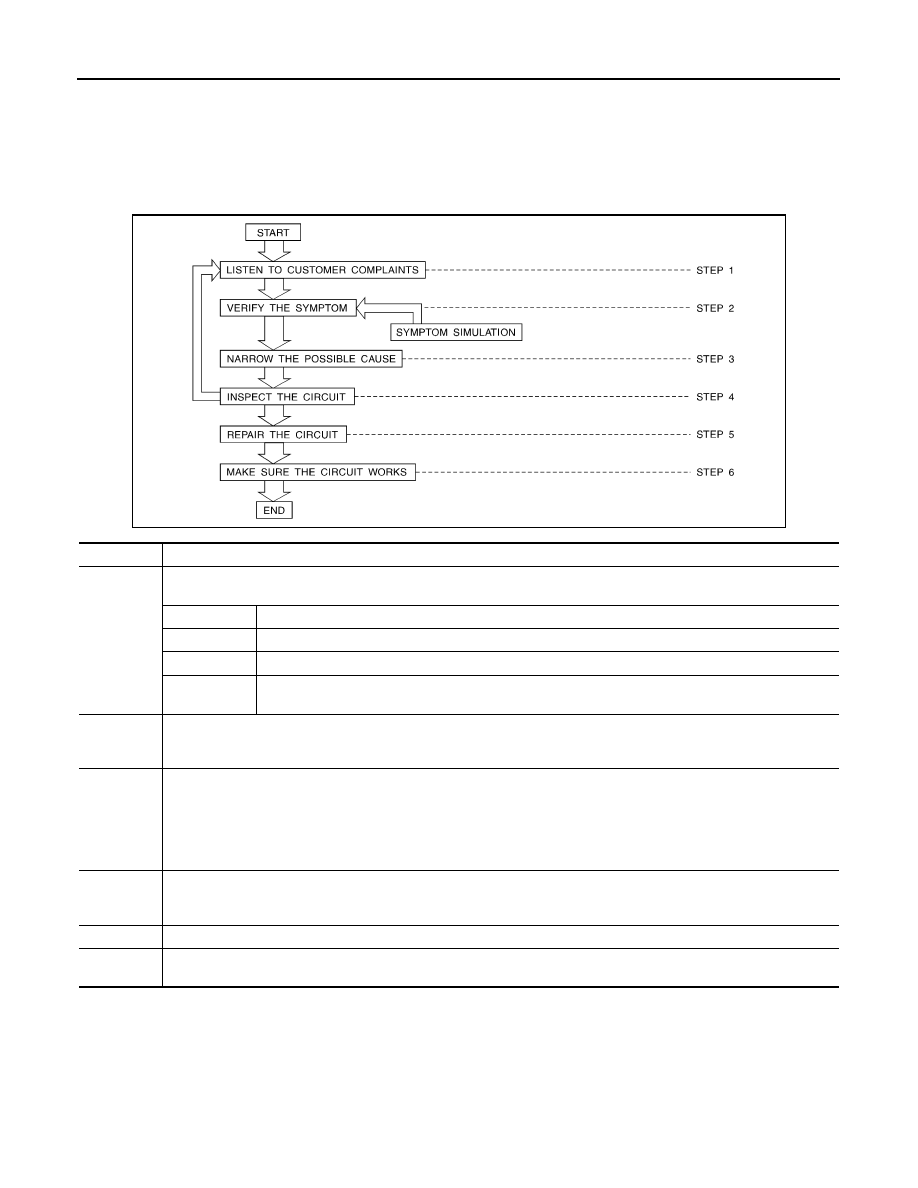

Work Flow

INFOID:0000000001095980

WORK FLOW

Control Units and Electrical Parts

INFOID:0000000001095981

PRECAUTIONS

• Never reverse polarity of battery terminals.

• Install only parts specified for a vehicle.

• Before replacing the control unit, check the input and output and functions of the component parts.

• Do not apply excessive force when disconnecting a connector.

SGI838

STEP

DESCRIPTION

STEP 1

Get detailed information about the conditions and the environment when the incident occurred.

The following are key pieces of information required to make a good analysis:

WHAT

Vehicle Model, Engine, Transmission/Transaxle and the System (i.e. Radio).

WHEN

Date, Time of Day, Weather Conditions, Frequency.

WHERE

Road Conditions, Altitude and Traffic Situation.

HOW

System Symptoms, Operating Conditions (Other Components Interaction).

Service History and if any After Market Accessories have been installed.

STEP 2

Operate the system, road test if necessary.

Verify the parameter of the incident.

If the problem cannot be duplicated, refer to “Incident Simulation Tests”.

STEP 3

Get the proper diagnosis materials together including:

• Power Supply Routing

• System Operation Descriptions

• Applicable Service Manual Sections

• Check for any Service Bulletins

Identify where to begin diagnosis based upon your knowledge of the system operation and the customer comments.

STEP 4

Inspect the system for mechanical binding, loose connectors or wiring damage.

Determine which circuits and components are involved and diagnose using the Power Supply Routing and Harness Lay-

outs.

STEP 5

Repair or replace the incident circuit or component.

STEP 6

Operate the system in all modes. Verify the system works properly under all conditions. Make sure you have not inad-

vertently created a new incident during your diagnosis or repair steps.

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст