Nissan Qashqai (2007-2010). Manual — part 171

P0420 THREE WAY CATALYST FUNCTION

EC-203

< COMPONENT DIAGNOSIS >

[HR16DE (WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

M

A

EC

N

P

O

Is the inspection result normal?

YES

>> INSPECTION END

NO

>> If the ratio is greater than above (0.75), it means three way catalyst does not operate properly. Go

to

.

Diagnosis Procedure

INFOID:0000000001056308

1.

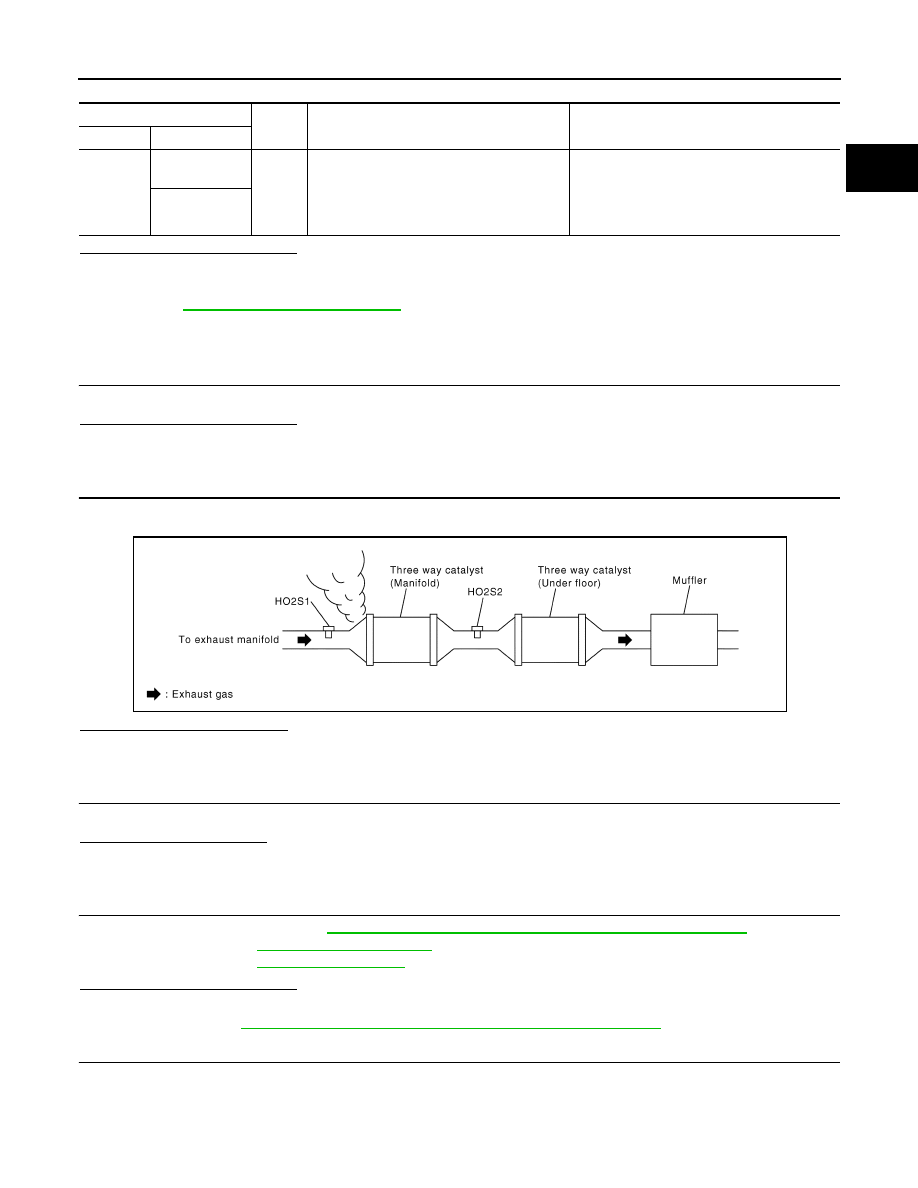

CHECK EXHAUST SYSTEM

Visually check exhaust tubes and muffler for dent.

Is the inspection result normal?

YES

>> GO TO 2.

NO

>> Repair or replace.

2.

CHECK EXHAUST GAS LEAK

1.

Start engine and run it at idle.

2.

Listen for an exhaust gas leak before the three way catalyst (manifold).

Is exhaust gas leak detected?

YES

>> Repair or replace.

NO

>> GO TO 3.

3.

CHECK INTAKE AIR LEAK

Listen for an intake air leak after the mass air flow sensor.

Is intake air leak detected?

YES

>> Repair or replace.

NO

>> GO TO 4.

4.

CHECK IGNITION TIMING AND IDLE SPEED

Check the following items. Refer to

EC-26, "BASIC INSPECTION : Special Repair Requirement"

.

Is the inspection result normal?

YES

>> GO TO 5.

NO

>> Follow the

EC-26, "BASIC INSPECTION : Special Repair Requirement"

.

5.

CHECK FUEL INJECTOR

1.

Stop engine and then turn ignition switch ON.

2.

Check the voltage between ECM harness connector and ground.

ECM

Ground

Condition

Specification

Connector

Terminal

F8

49

(HO2S1 signal)

Ground

Keeping engine speed at 2,000 rpm constant

under no load

Switching freqency ratio ( A/B) : Less than 0.75

A : Heated oxygen sensor 2 voltage switching

frequency

B : Heated oxygen sensor 1 voltage switching

frequency

50

(HO2S2 signal)

SEC502D

EC-204

< COMPONENT DIAGNOSIS >

[HR16DE (WITH EURO-OBD)]

P0420 THREE WAY CATALYST FUNCTION

Is the inspection result normal?

YES

>> GO TO 6.

NO

>> Perform

.

6.

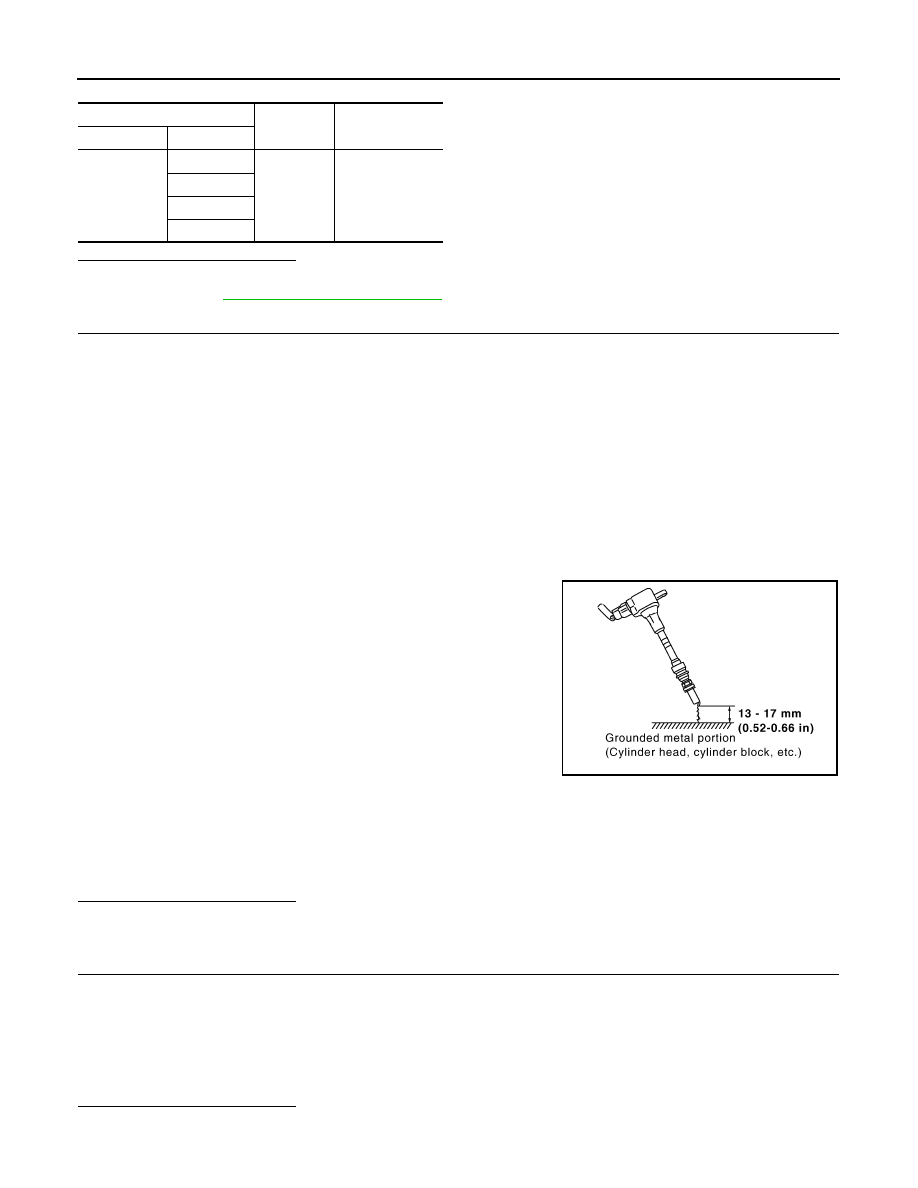

CHECK FUNCTION OF IGNITION COIL-I

CAUTION:

Do the following procedure in the place where ventilation is good without the combustible.

1.

Turn ignition switch OFF.

2.

Remove fuel pump fuse in IPDM E/R to release fuel pressure.

NOTE:

Do not use CONSULT-III to release fuel pressure, or fuel pressure applies again during the following pro-

cedure.

3.

Start engine.

4.

After engine stalls, crank it two or three times to release all fuel pressure.

5.

Turn ignition switch OFF.

6.

Remove all ignition coil harness connectors to avoid the electrical discharge from the ignition coils.

7.

Remove ignition coil and spark plug of the cylinder to be checked.

8.

Crank engine for 5 seconds or more to remove combustion gas in the cylinder.

9.

Connect spark plug and harness connector to ignition coil.

10. Fix ignition coil using a rope etc. with gap of 13 - 17 mm (0.52 -

0.66 in) between the edge of the spark plug and grounded metal

portion as shown in the figure.

11. Crank engine for about 3 seconds, and check whether spark is

generated between the spark plug and the grounded metal por-

tion.

CAUTION:

• Do not approach to the spark plug and the ignition coil

within 50 cm (19.7 in). Be careful not to get an electrical

shock while checking, because the electrical discharge

voltage becomes 20kV or more.

• It might cause to damage the ignition coil if the gap of more than 17 mm (0.66 in) is taken.

NOTE:

When the gap is less than 13 mm (0.52 in), the spark might be generated even if the coil is mal-

functioning.

Is the inspection result normal?

YES

>> GO TO 10.

NO

>> GO TO 7.

7.

CHECK FUNCTION OF IGNITION COIL-II

1.

Turn ignition switch OFF.

2.

Disconnect spark plug and connect a known-good spark plug.

3.

Crank engine for about 3 seconds, and recheck whether spark is generated between the spark plug and

the grounded metal portion.

Is the inspection result normal?

YES

>> GO TO 8.

ECM

Ground

Voltage

Connector

Terminal

F7

31

Ground

Battery voltage

30

29

25

Spark should be generated.

JMBIA0066GB

Spark should be generated.

P0420 THREE WAY CATALYST FUNCTION

EC-205

< COMPONENT DIAGNOSIS >

[HR16DE (WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

M

A

EC

N

P

O

NO

>> Check ignition coil, power transistor and their circuits. Refer to

.

8.

CHECK SPARK PLUG

Check the initial spark plug for fouling, etc.

Is the inspection result normal?

YES

>> Replace spark plug(s) with standard type one(s). For

.

NO

>> Repair or clean spark plug. Then GO TO 9

9.

CHECK FUNCTION OF IGNITION COIL-III

1.

Reconnect the initial spark plugs.

2.

Crank engine for about three seconds, and recheck whether spark is generated between the spark plug

and the grounded portion.

Is the inspection result normal?

YES

>> INSPECTION END

NO

>> Replace spark plug(s) with standard type one(s). For spark plug type, refer to

.

10.

CHECK FUEL INJECTOR

1.

Turn ignition switch OFF.

2.

Remove fuel injector assembly.

Refer to

EM-35, "Removal and Installation"

Keep fuel hose and all fuel injectors connected to fuel tube.

3.

Disconnect all ignition coil harness connectors.

4.

Reconnect all fuel injector harness connectors disconnected.

5.

Turn ignition switch ON.

Does fuel drip from fuel injector?

YES

>> GO TO 11.

NO

>> Replace the fuel injector(s) from which fuel is dripping.

11.

CHECK INTERMITTENT INCIDENT

GI-39, "Intermittent Incident"

.

Is the trouble fixed?

YES

>> INSPECTION END

NO

>> Replace three way catalyst assembly.

SEF156I

Spark should be generated.

EC-206

< COMPONENT DIAGNOSIS >

[HR16DE (WITH EURO-OBD)]

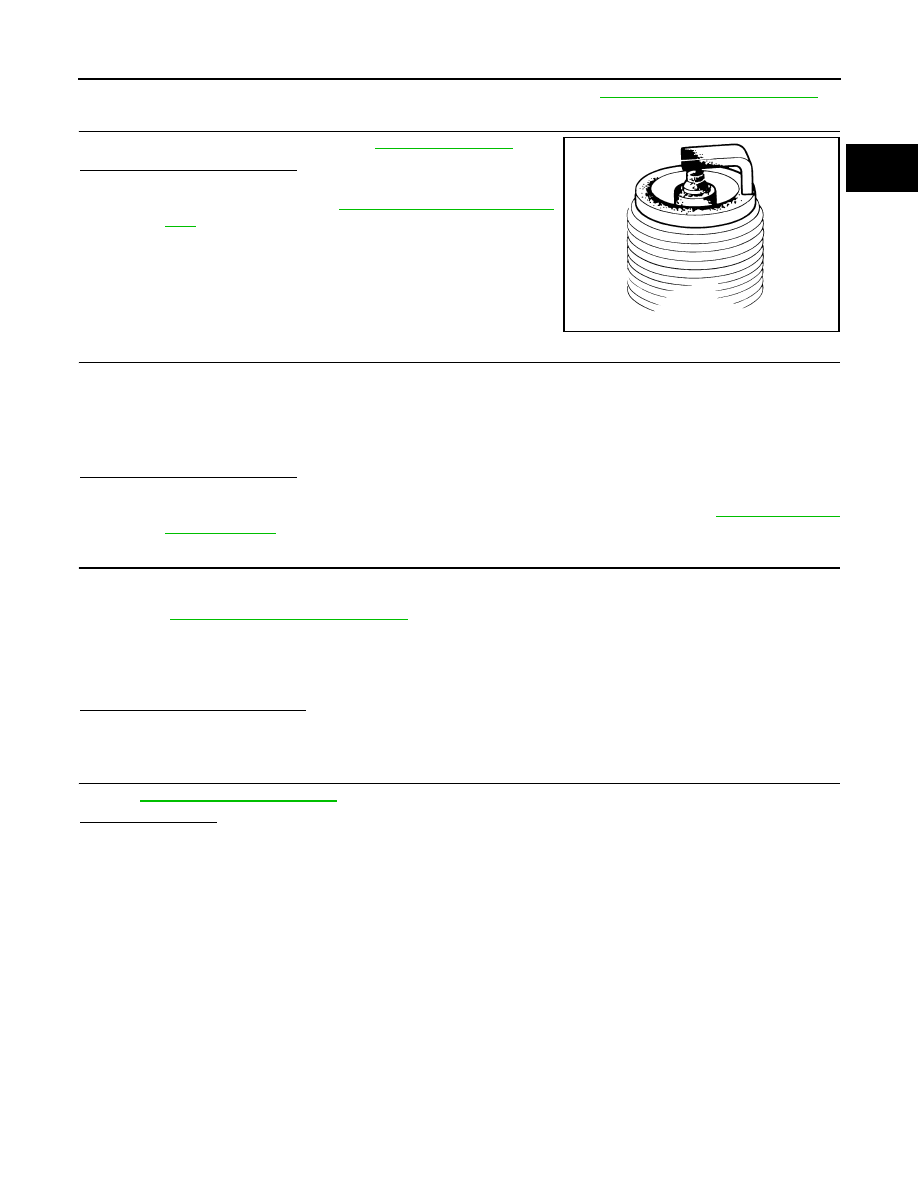

P0444 EVAP CANISTER PURGE VOLUME CONTROL SOLENOID VALVE

P0444 EVAP CANISTER PURGE VOLUME CONTROL SOLENOID VALVE

Description

INFOID:0000000001056319

The EVAP canister purge volume control solenoid valve uses a ON/

OFF duty to control the flow rate of fuel vapor from the EVAP canis-

ter. The EVAP canister purge volume control solenoid valve is

moved by ON/OFF pulses from the ECM. The longer the ON pulse,

the greater the amount of fuel vapor that will flow through the valve.

DTC Logic

INFOID:0000000001056320

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.

CONDITIONING

If DTC Confirmation Procedure has been previously conducted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

TESTING CONDITION:

Before performing the following procedure, confirm battery voltage is more than 11V at idle.

>> GO TO 2.

2.

PERFORM DTC CONFIRMATION PROCEDURE

1.

Start engine and let it idle for at least 13 seconds.

2.

Check 1st trip DTC.

Is 1st trip DTC detected?

YES

>> Go to

NO

>> INSPECTION END

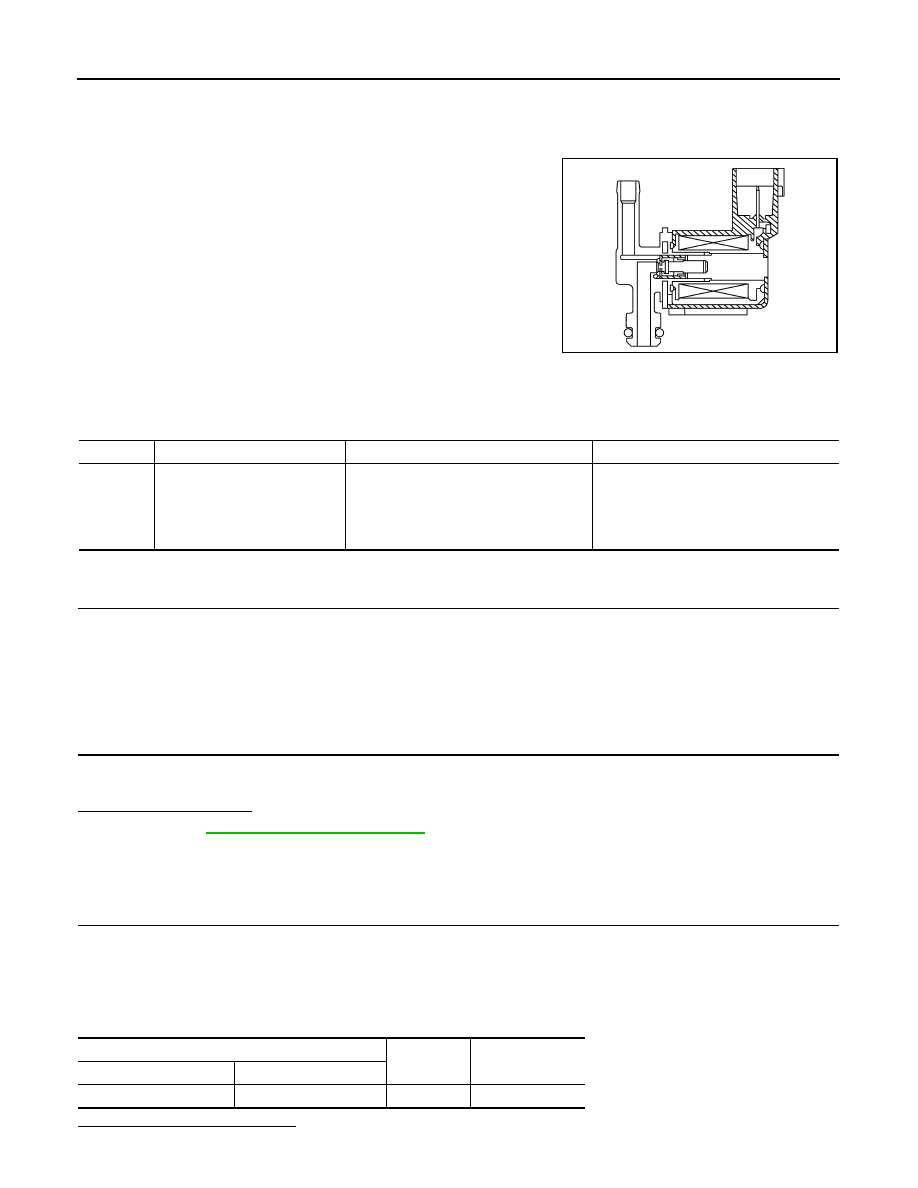

Diagnosis Procedure

INFOID:0000000001056321

1.

CHECK EVAP CANISTER PURGE VOLUME CONTROL SOLENOID VALVE POWER SUPPLY CIRCUIT

1.

Turn ignition switch OFF.

2.

Disconnect EVAP canister purge volume control solenoid valve harness connector.

3.

Turn ignition switch ON.

4.

Check the voltage between EVAP canister purge volume control solenoid valve harness connector and

ground.

Is the inspection result normal?

PBIA9215J

DTC No.

Trouble diagnosis name

DTC detecting condition

Possible cause

P0444

EVAP canister purge volume

control solenoid valve circuit

open

An excessively low voltage signal is sent

to ECM through the valve

• Harness or connectors

(The solenoid valve circuit is open or

shorted.)

• EVAP canister purge volume control so-

lenoid valve

EVAP canister purge volume control solenoid valve

Ground

Voltage

Connector

Terminal

F32

1

Ground

Battery voltage

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст