Nissan Qashqai (2007-2010). Manual — part 99

OIL FILTER

LU-9

< ON-VEHICLE MAINTENANCE >

[HR16DE]

C

D

E

F

G

H

I

J

K

L

M

A

LU

N

P

O

OIL FILTER

Removal and Installation

INFOID:0000000000902504

REMOVAL

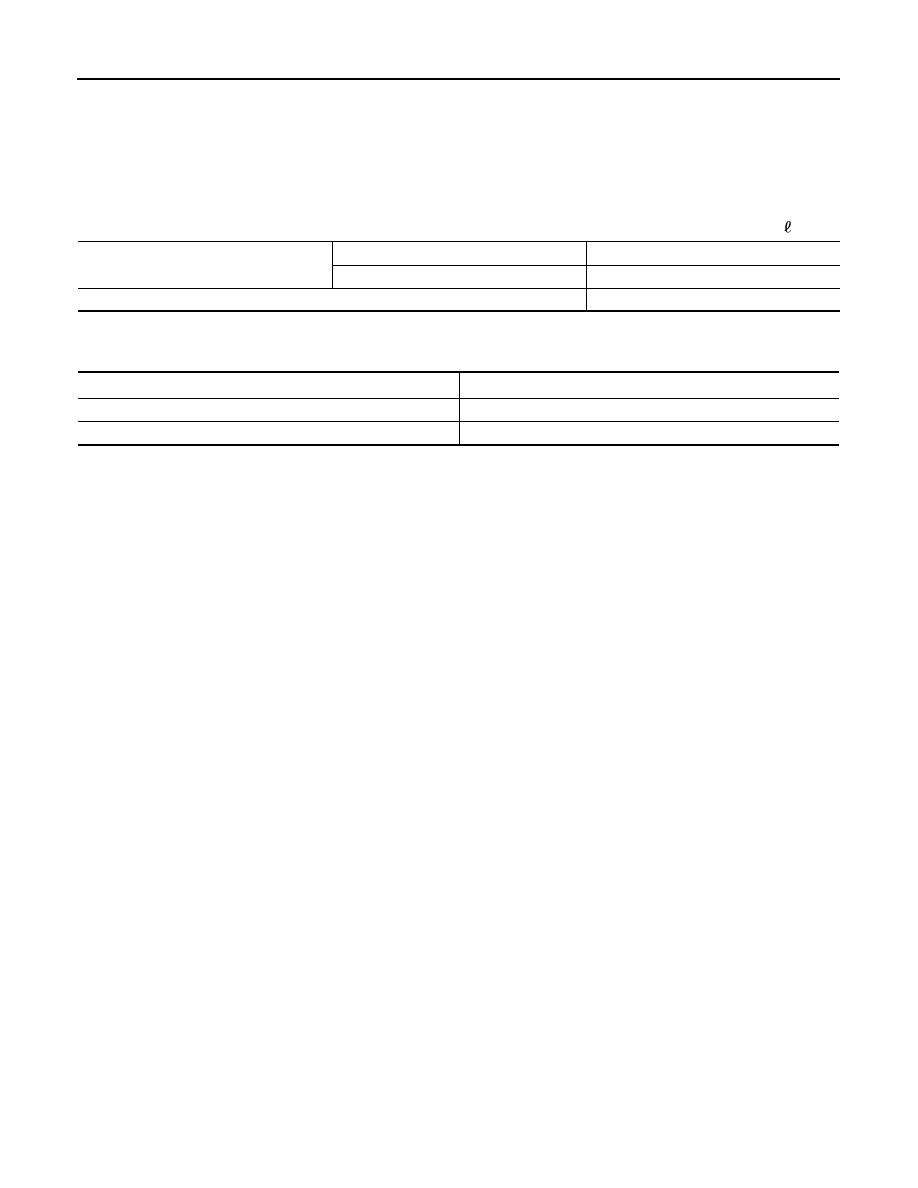

• Using oil filter wrench [SST: KV10115801] (A), remove oil filter.

CAUTION:

• Oil filter is provided with relief valve. Use Genuine NISSAN

Oil Filter or equivalent.

• Be careful not to get burned when engine and engine oil

may be hot.

• When removing, prepare a shop cloth to absorb any engine

oil leakage or spillage.

• Completely wipe off any engine oil that adheres to engine

and vehicle.

INSTALLATION

1.

Remove foreign materials adhering to the oil filter installation surface.

2.

Apply new engine oil to the oil seal contact surface of new oil fil-

ter.

3.

Screw oil filter manually until it touches the installation surface,

then tighten it by 2/3 turn. Or tighten to specification.

Inspection

INFOID:0000000000902415

INSPECTION AFTER INSTALLATION

1.

Check the engine oil level. Refer to

.

2.

Start the engine, and check there is no leak of engine oil.

3.

Stop the engine and wait for 10 minutes.

4.

Check the engine oil level, and adjust the level. Refer to

.

: Vehicle font

PBIC3818E

SMA010

Oil filter:

: 17.7 N·m (1.8 kg-m, 13 ft-lb)

SMA229B

LU-10

< SERVICE DATA AND SPECIFICATIONS (SDS)

[HR16DE]

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

Periodical Maintenance Specification

INFOID:0000000000902428

ENGINE OIL CAPACITY (APPROXIMATE)

Unit:

(lmp qt)

Engine Oil Pressure

INFOID:0000000000902429

*: Engine oil temperature at 80

°

C (176

°

F)

Drain and refill

With oil filter change

4.3 (3-3/4)

Without oil filter change

4.1 (3-5/8)

Dry engine (Overhaul)

4.8 (4-1/4)

Engine speed (rpm)

Approximate discharge pressure* [kPa (bar, kg/cm

2

, psi)]

Idle speed

More than 60 (0.60, 0.61, 9)

2,000

More than 270 (2.7, 2.8, 39)

DESCRIPTION

LU-11

< FUNCTION DIAGNOSIS >

[MR20DE]

C

D

E

F

G

H

I

J

K

L

M

A

LU

N

P

O

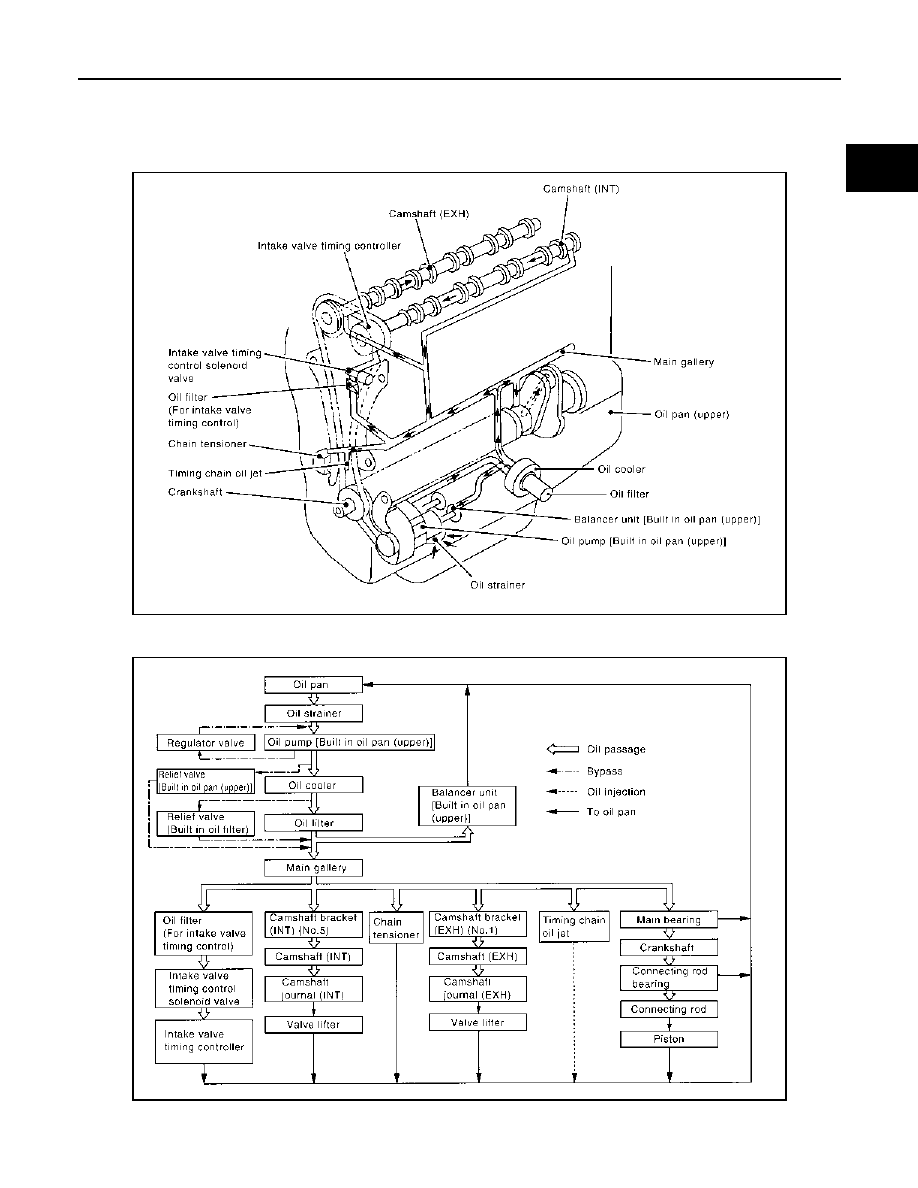

FUNCTION DIAGNOSIS

DESCRIPTION

Engine Lubrication System

INFOID:0000000000902583

Engine Lubrication System Schematic

INFOID:0000000000902584

PBIC3912E

PBIC3913E

LU-12

< PRECAUTION >

[MR20DE]

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Liquid Gasket

INFOID:0000000000902580

LIQUID GASKET APPLICATION PROCEDURE

1.

Remove old liquid gasket adhering to the liquid gasket application surface and the mating surface.

• Remove liquid gasket completely from the liquid gasket application surface, mounting bolts, and bolt

holes.

2.

Wipe the liquid gasket application surface and the mating surface with white gasoline (lighting and heating

use) to remove adhering moisture, grease and foreign materials.

3.

Apply liquid gasket to the liquid gasket application surface.

Use Genuine liquid gasket or equivalent.

• Within five minutes of liquid gasket application, install the mating component.

• If liquid gasket protrudes, wipe it off immediately.

• Do not retighten mounting bolts or nuts after the installation.

• After 30 minutes or more have passed from the installation, fill engine oil and engine coolant.

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст