Nissan Qashqai (2007-2010). Manual — part 881

HA-94

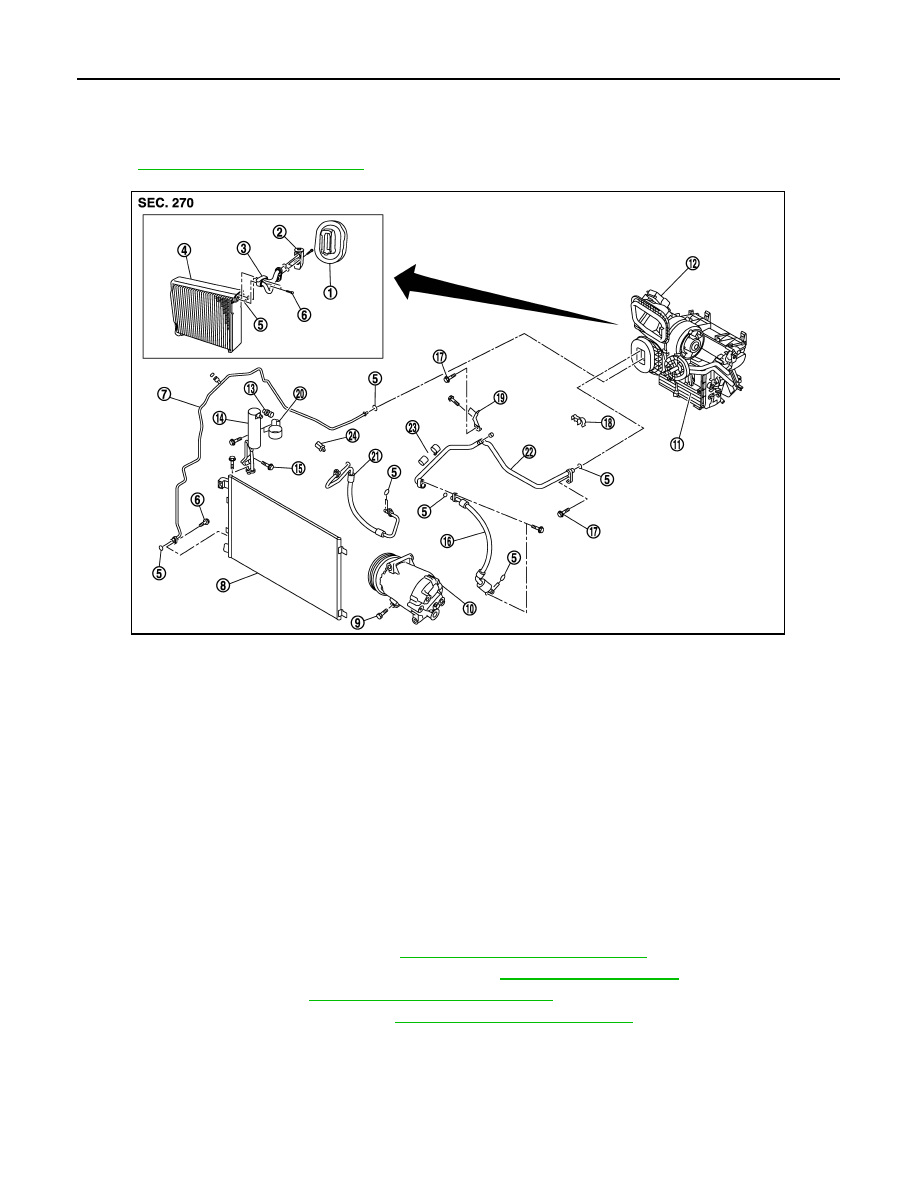

< ON-VEHICLE REPAIR >

[AUTOMATIC AIR CONDITIONER (K9K)]

HIGH-PRESSURE FLEXIBLE HOSE

HIGH-PRESSURE FLEXIBLE HOSE

Exploded View

INFOID:0000000001093916

HA-69, "Refrigerant Connection"

.

Removal and Installation

INFOID:0000000001093917

REMOVAL

1.

Use a refrigerant collecting equipment (for HFC-134a) to discharge the refrigerant.

2.

Remove engine cover ornament. Refer to

EM-266, "Removal and Installation"

3.

Remove air intake hose (RH) and air duct (LH). Refer to

4.

Remove front grille. Refer to

EXT-17, "Removal and Installation"

5.

Remove radiator air guide (RH). Refer to

CO-56, "Removal and Installation"

1.

Heater sealing

2.

Expansion valve

3.

Low pressure pipe 1 and high pres-

sure pipe 2 assembly

4.

Evaporator

5.

O-ring

6.

Connector pipe fixing bolt

7.

High pressure pipe 1

8.

Condenser assembly

9.

Fixing bolt

10. Compressor

11.

Heater & cooling unit assembly

12. Heater & blower unit assembly

13. Refrigerant pressure sensor

14. Liquid tank

15. Liquid tank fixing screw

16. Low pressure flexible hose

17. Fixing bolt

18. Pipes fixing clip

19. Low & high pressure pipe bracket

20. Liquid tank fixing bracket

21. High pressure flexible hose

22. Low pressure pipe 2

23. Low pressure pipe fixing clamp as-

sembly

24. Pipe mantening clip

E1KIA0063GB

HIGH-PRESSURE FLEXIBLE HOSE

HA-95

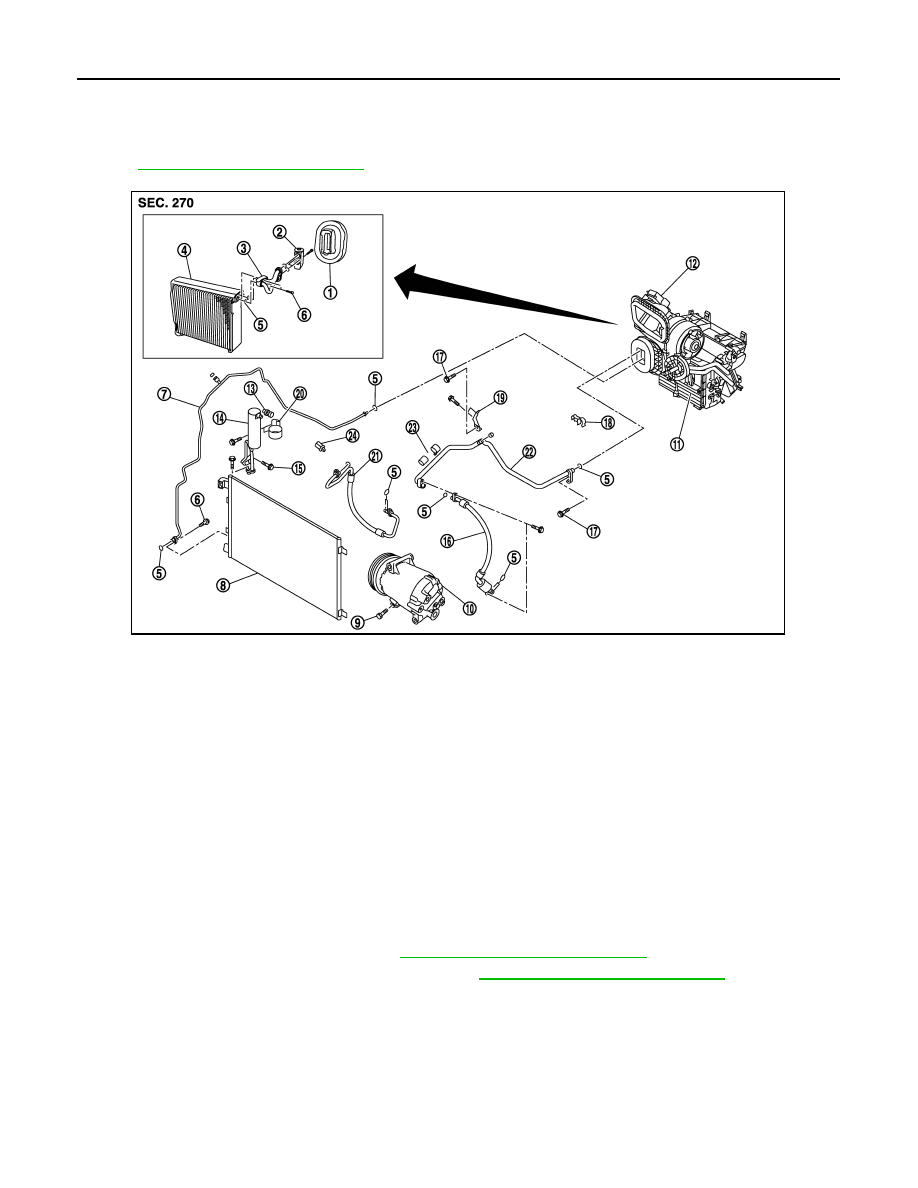

< ON-VEHICLE REPAIR >

[AUTOMATIC AIR CONDITIONER (K9K)]

C

D

E

F

G

H

J

K

L

M

A

B

HA

N

O

P

6.

Remove high pressure flexible hose fixing bolt (1) from con-

denser (3), then pull high pressure flexible hose (2) to remove it

from condenser.

CAUTION:

Cap or wrap the joint of high-pressure flexible hose and

condenser assembly with suitable material such as vinyl

tape to avoid the entry of air.

7.

Remove high pressure flexible hose fixing bolt (1) from com-

pressor, then pull high pressure flexible hose (2) to remove it

from compressor.Remove high pressure flexible hose.

CAUTION:

Cap or wrap the joint of compressor and high-pressure flex-

ible hose with suitable material such as vinyl tape to avoid

the entry of air.

INSTALLATION

Installation is basically the reverse order of removal.

CAUTION:

• Replace O-rings of high-pressure flexible hose with new ones, and then apply compressor oil to it

when installing it.

• Female-side piping connection is thin and easy to deform. Slowly insert the male-side piping

straight in axial direction.

• Insert piping securely until a click is heard.

• After piping connection is completed, pull male-side piping by hand to make sure that connection

does not come loose.

• When recharging refrigerant, check for leaks.

E1KIA0043GB

High pressure fixing bolt to condenser

: 4.4 N·m (0.45 kg-m, 39 in-lb)

High pressure fixing bolt to compressor

: 8 N·m (0.8 kg-m, 71 in-lb)

E1KIA0044GB

HA-96

< ON-VEHICLE REPAIR >

[AUTOMATIC AIR CONDITIONER (K9K)]

HIGH-PRESSURE PIPE 1 (ENGINE COMPARTMENT)

HIGH-PRESSURE PIPE 1 (ENGINE COMPARTMENT)

Exploded View

INFOID:0000000001093918

HA-69, "Refrigerant Connection"

.

Removal and Installation

INFOID:0000000001093919

REMOVAL

1.

Use a refrigerant collecting equipment (for HFC-134a) to discharge the refrigerant.

2.

Remove engine cover ornament. Refer to

EM-266, "Removal and Installation"

3.

Remove intake hose (RH) and air duct (LH). Refer to

EM-265, "Removal and Installation"

.

1.

Heater sealing

2.

Expansion valve

3.

Low pressure pipe 1 and high pres-

sure pipe 2 assembly

4.

Evaporator

5.

O-ring

6.

Connector pipe fixing bolt

7.

High pressure pipe 1

8.

Condenser assembly

9.

Fixing bolt

10. Compressor

11.

Heater & cooling unit assembly

12. Heater & blower unit assembly

13. Refrigerant pressure sensor

14. Liquid tank

15. Liquid tank fixing screw

16. Low pressure flexible hose

17. Fixing bolt

18. Pipes fixing clip

19. Low & high pressure pipe bracket

20. Liquid tank fixing bracket

21. High pressure flexible hose

22. Low pressure pipe 2

23. Low pressure pipe fixing clamp as-

sembly

24. Pipe mantening clip

E1KIA0063GB

HIGH-PRESSURE PIPE 1 (ENGINE COMPARTMENT)

HA-97

< ON-VEHICLE REPAIR >

[AUTOMATIC AIR CONDITIONER (K9K)]

C

D

E

F

G

H

J

K

L

M

A

B

HA

N

O

P

4.

Pull engine room insulator, then remove pipes bracket fixing bolt

(1), from expansion valve, then release pipe fixing bracket from

high pressure pipe 1 (B), as shown in order (1) to (3), to discon-

nect it from expansion valve.

CAUTION:

Cap or wrap the joint of the high pressure pipe 1, and

expansion valve in, with suitable material such as vinyl tape

to avoid the entry of air.

5.

Remove high pressure pipe 1 (1) from clip (A).

Remove high-pressure pipe 1 mounting bolt (A) from condenser

(2).

CAUTION:

Cap or wrap the joint of the high pressure pipe 1, and con-

denser, with suitable material such as vinyl tape to avoid

the entry of air.

Remove high pressure pipe 1 (1).

INSTALLATION

Installation is basically the reverse order of removal.

CAUTION:

• Replace O-rings of high-pressure pipe 1 with new ones, and then apply compressor oil to it when

installing it.

• Female-side piping connection is thin and easy to deform. Slowly insert the male-side piping

straight in axial direction.

• Insert piping securely until a click is heard.

• After piping connection is completed, pull male-side piping by hand to make sure that connection

does not come loose.

• When recharging refrigerant, check for leaks.

E1IIA0011GB

E1KIA0045ZZ

E1KIA0047GB

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст