Nissan Qashqai (2007-2010). Manual — part 859

HA-6

HIGH-PRESSURE FLEXIBLE HOSE . . . ..

Exploded View . . . . . . . . . . . . . ...

Removal and Installation . . . . . . . . . ...

HIGH-PRESSURE PIPE 1 (ENGINE COM-

PARTMENT) . . . . . . . . . . . . .

Exploded View . . . . . . . . . . . . . ...

Removal and Installation . . . . . . . . . ...

LOW-PRESSURE PIPE 1 AND HIGH-PRES-

SURE PIPE 2 . . . . . . . . . . . . ...

Exploded View . . . . . . . . . . . . . ...

Removal and Installation . . . . . . . . . ...

CONDENSER . . . . . . . . . . . . ..

Exploded View . . . . . . . . . . . . . ...

Removal and Installation . . . . . . . . . ...

LIQUID TANK . . . . . . . . . . . . ..

Exploded View . . . . . . . . . . . . . ...

Removal and Installation . . . . . . . . . ...

REFRIGERANT PRESSURE SENSOR . . ...

Exploded View . . . . . . . . . . . . . ..

Removal and Installation . . . . . . . . . ...

EVAPORATOR . . . . . . . . . . . . .

Exploded View . . . . . . . . . . . . . ..

Removal and Installation . . . . . . . . . ...

EXPANSION VALVE . . . . . . . . . .

Exploded View . . . . . . . . . . . . . ..

Removal and Installation . . . . . . . . . ...

SERVICE DATA AND SPECIFICATIONS

(SDS) . . . . . . . . . . . . . . .

SERVICE DATA AND SPECIFICATIONS

(SDS) . . . . . . . . . . . . . . . .

Compressor . . . . . . . . . . . . . . ..

Lubricant . . . . . . . . . . . . . . . ...

Refrigerant . . . . . . . . . . . . . . .

Engine Idling Speed . . . . . . . . . . . ..

DIAGNOSIS AND REPAIR WORKFLOW

HA-7

< BASIC INSPECTION >

[AUTOMATIC AIR CONDITIONER (HR/MR)]

C

D

E

F

G

H

J

K

L

M

A

B

HA

N

O

P

BASIC INSPECTION

DIAGNOSIS AND REPAIR WORKFLOW

Work Flow

INFOID:0000000001093748

DETAILED FLOW

1.

LISTEN TO CUSTOMER COMPLAINT

Listen to customer complaint. (Get detailed information about the conditions and environment when the symp-

tom occurs.)

>> GO TO 2.

2.

VERIFY THE SYMPTOM WITH OPERATIONAL CHECK

Verify the symptom with operational check. Refer to

HAC-6, "Description & Inspection"

>> GO TO 3.

3.

GO TO APPROPRIATE TROUBLE DIAGNOSIS

Go to appropriate trouble diagnosis (Refer to

HAC-108, "Diagnosis Chart By Symptom"

>> GO TO 4.

4.

REPAIR OR REPLACE

Repair or replace the specific parts

>> GO TO 5.

5.

FINAL CHECK

Final check.

Is the inspection result normal?

YES

>> CHECK OUT

NO

>> GO TO 3.

HA-8

< FUNCTION DIAGNOSIS >

[AUTOMATIC AIR CONDITIONER (HR/MR)]

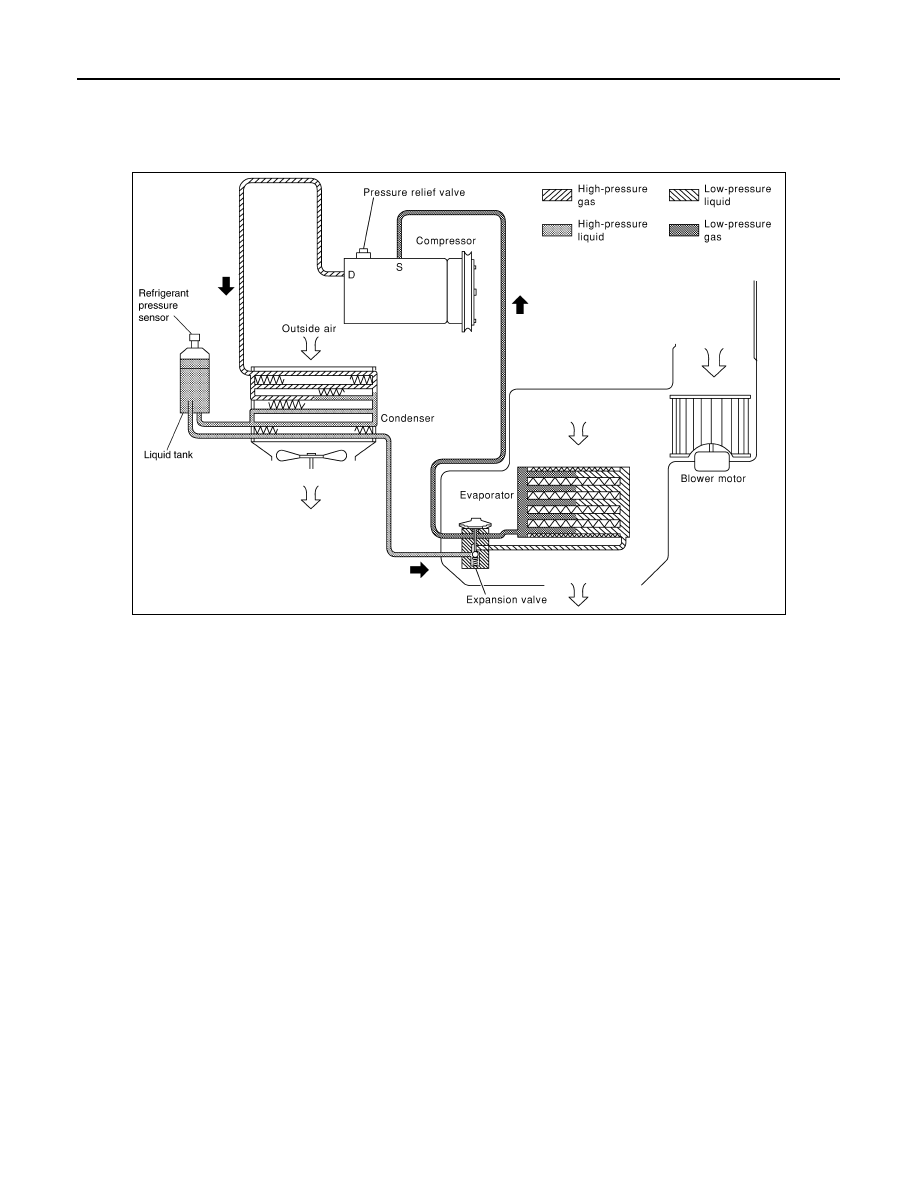

REFRIGERATION SYSTEM

FUNCTION DIAGNOSIS

REFRIGERATION SYSTEM

System Diagram

INFOID:0000000001093749

System Description

INFOID:0000000001093750

REFRIGERANT CYCLE

Refrigerant Flow

The refrigerant flows from the compressor, through the condenser with liquid tank, through the evaporator, and

back to the compressor. The refrigerant evaporation in the evaporator is controlled by an externally equalized

expansion valve, located inside the evaporator case.

Freeze Protection

To prevent evaporator frozen up, the evaporator air temperature is monitored, and the voltage signal to the

display and A/C auto amp. will make the A/C relay go OFF and stop the compressor.

REFRIGERANT SYSTEM PROTECTION

Refrigerant Pressure Sensor

The refrigerant system is protected against excessively high- or low-pressures by the refrigerant pressure sen-

sor, located on the condenser. If the system pressure rises above, or falls below the specifications, the refrig-

erant pressure sensor detects the pressure inside the refrigerant line and sends the voltage signal to the ECM.

ECM makes the A/C relay go OFF and stops the compressor when pressure on the high-pressure side

detected by refrigerant pressure sensor is over about 3,119 kPa (31.8 kg/cm

2

, 452 psi), or below about 118

kPa (1.2 kg/cm

2

, 17 psi).

Pressure Relief Valve

The refrigerant system is also protected by a pressure relief valve, located in the rear head of the compressor.

When the pressure of refrigerant in the system increases to an unusual level [more than 3,628 kPa (37 kg/

cm

2

, 526 psi)], the release port on the pressure relief valve automatically opens and releases refrigerant into

the atmosphere.

LUBRICANT

RJIA1552E

REFRIGERATION SYSTEM

HA-9

< FUNCTION DIAGNOSIS >

[AUTOMATIC AIR CONDITIONER (HR/MR)]

C

D

E

F

G

H

J

K

L

M

A

B

HA

N

O

P

Maintenance of Lubricant Quantity in Compressor

The lubricant in the compressor circulates through the system with the refrigerant. Add lubricant to compres-

sor when replacing any component or after a large refrigerant leakage occurred. It is important to maintain the

specified amount.

If lubricant quantity is not maintained properly, the following malfunctions may result:

• Lack of lubricant: May lead to a seized compressor.

• Excessive lubricant: Inadequate cooling (thermal exchange interference)

Lubricant

Component Parts Location

INFOID:0000000001093751

Name

: Nissan A/C System Oil Type S

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст