Nissan Qashqai (2007-2010). Manual — part 472

P2263 TC SYSTEM

EC-1407

< COMPONENT DIAGNOSIS >

[K9K]

C

D

E

F

G

H

I

J

K

L

M

A

EC

N

P

O

Check turbocharger.

Is the inspection result normal?

Yes

>> Repair or replace.

No

>> GO TO 6.

6.

CHECK TURBOCHARGER BOOST CONTROL SOLENOID VALVE POWER SUPPLY CIRCUIT

1.

Disconnect turbocharger boost control solenoid valve harness connector.

2.

Turn ignition switch ON.

3.

Check the voltage between turbocharger boost control solenoid valve harness connector and ground.

Is the inspection result normal?

YES

>> GO TO 7.

NO

>> Repair open circuit or short to ground or short to power in harness or connectors.

7.

CHECK TURBOCHARGER BOOST CONTROL SOLENOID VALVE OUTPUT SIGNAL CIRCUIT FOR

OPEN AND SHORT

1.

Turn ignition switch OFF.

2.

Disconnect ECM harness connector.

3.

Check the continuity between turbocharger boost control solenoid valve harness connector and ECM har-

ness connector.

4.

Also check harness for short to ground and short to power.

Is the inspection result normal?

YES

>> GO TO 8.

NO

>> Repair open circuit or short to ground or short to power in harness or connectors.

8.

CHECK TURBOCHARGER BOOST CONTROL SOLENOID VALVE

EC-1328, "Component Inspection"

.

Is the inspection result normal?

YES

>> GO TO 9.

NO

>> Replace turbocharger boost control solenoid valve.

9.

CHECK TURBOCHARGER BOOST SENSOR

EC-1330, "Component Inspection"

.

Is the inspection result normal?

YES

>> GO TO 10.

NO

>> Replace turbocharger boost sensor.

10.

CHECK THROTTLE CONTROL MOTOR

EC-1405, "Component Inspection"

.

Is the inspection result normal?

YES

>> GO TO 11.

NO

>> Replace turbocharger boost sensor.

11.

CHECK INTERMITTENT INCIDENT

GI-39, "Intermittent Incident"

.

>> INSPECTION END

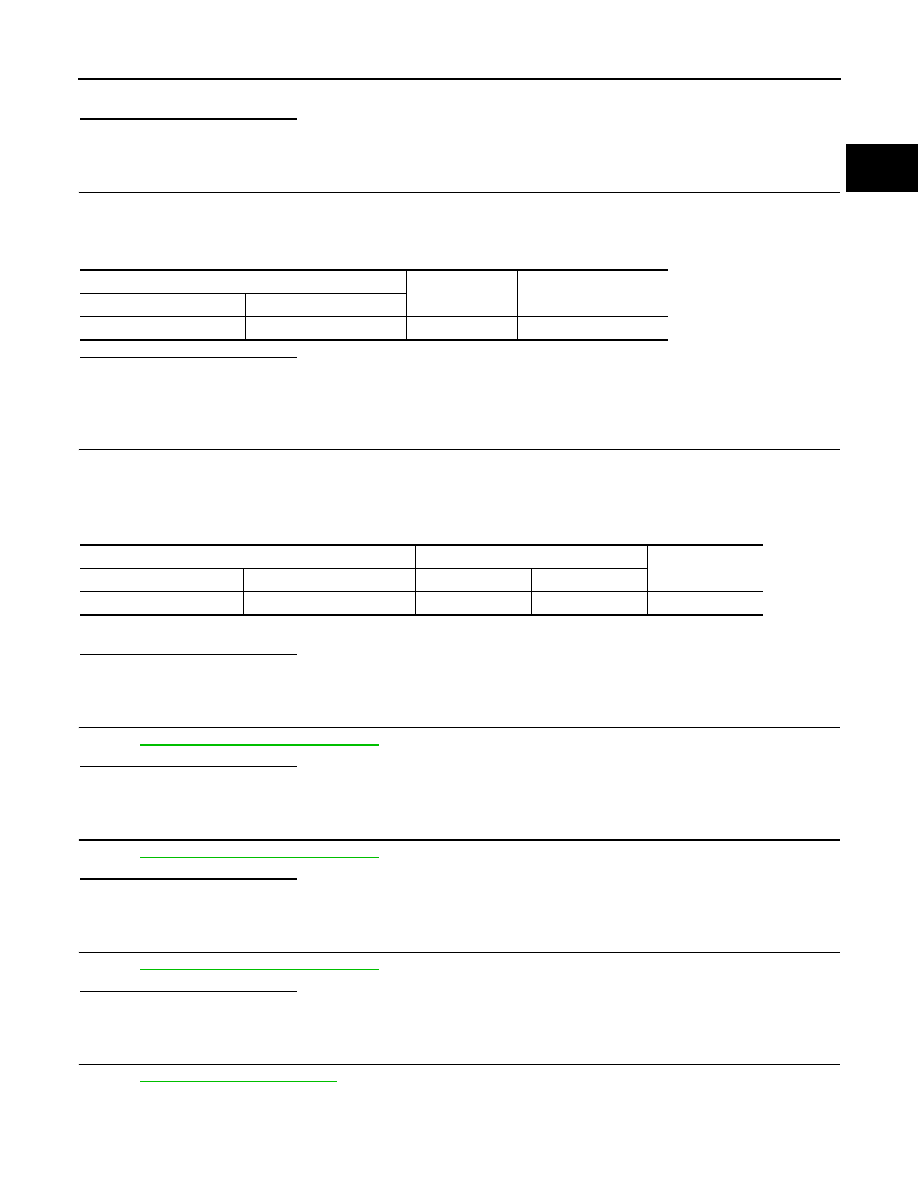

Turbocharger boost control solenoid valve

Ground

Voltage

Connector

Terminal

E55

2

Ground

Battery voltage

Turbocharger boost control solenoid valve

ECM

Continuity

Connector

Terminal

Connector

Terminal

E55

1

F68

52

Existed

EC-1408

< COMPONENT DIAGNOSIS >

[K9K]

P2299 ACCELERATOR/BRAKE PEDAL POSITION INCONSISTENCY

P2299 ACCELERATOR/BRAKE PEDAL POSITION INCONSISTENCY

DTC Logic

INFOID:0000000001115113

DTC DETECTION LOGIC

NOTE:

• Special note:

The brake and accelerator pedals were detected as depressed simultaneously for 30 seconds.

• If the DTC is present:

- Malfunction indicator (Red) lights up.

Diagnosis Procedure

INFOID:0000000000970929

1.

CHECK GROUND CONNECTIONS

1.

Turn ignition switch OFF.

2.

Check ground connection E17. Refer to Ground inspection in

Is the inspection result normal?

YES

>> GO TO 2.

NO

>> Repair or replace ground connection.

2.

CHECK BRAKE SWITCH CIRCUIT

1.

Turn ignition switch ON.

2.

Check the voltage between ECM harness connector and ground.

Is the inspection result normal?

YES

>> GO TO 3.

NO

>> GO TO 7.

3.

CHECK ACCELERATOR PEDAL POSITION SENSOR POWER SUPPLY CIRCUIT

1.

Turn ignition switch OFF.

2.

Disconnect accelerator pedal position sensor harness connector.

3.

Turn ignition switch ON.

4.

Check the voltage between accelerator pedal position sensor connector and ground.

Is the inspection result normal?

YES

>> GO TO 4.

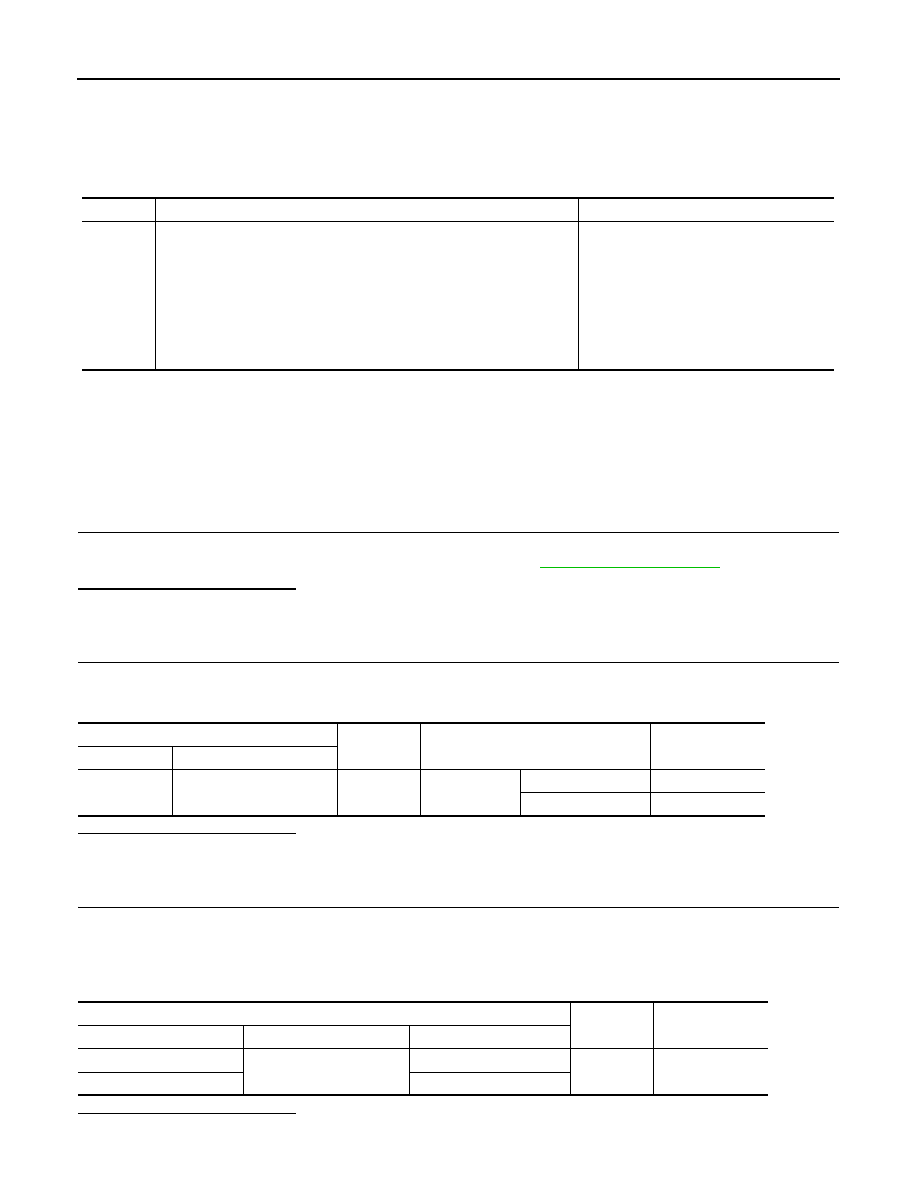

DTC No.

Trouble diagnosis name

Possible cause

P2299

ACCELERATOR PEDAL/BRAKE PEDAL INCONSISTENCY

• 1.DEF: Inconsistency

• Harness or connectors

(APP sensor 1 and 2 circuit is open or

shorted.)

(Stop lamp switch circuit is open or short-

ed.)

• Accelerator pedal position sensor

(APP sensor 1 and 2.)

• Stop lamp switch

• Accelerator pedal

ECM

Ground

Condition

Voltage

Connector

Terminal

E60

115

(ASCD brake switch)

Ground

Brake pedal

Fully released

0V

Slightly depressed

Battery voltage

Accelerator pedal position sensor

Ground

Voltage

Sensor

Connector

Terminal

1

E110

4

Ground

Approx. 5V

2

5

P2299 ACCELERATOR/BRAKE PEDAL POSITION INCONSISTENCY

EC-1409

< COMPONENT DIAGNOSIS >

[K9K]

C

D

E

F

G

H

I

J

K

L

M

A

EC

N

P

O

NO

>> Repair open circuit or short to ground or short to power in harness or connectors.

4.

CHECK ACCELERATOR PEDAL POSITION SENSOR GROUND CIRCUIT FOR OPEN AND SHORT

1.

Turn ignition switch OFF.

2.

Disconnect ECM harness connector.

3.

Check the continuity between accelerator pedal position sensor harness connector and ECM harness

connector.

4.

Also check harness for short to ground and short to power.

Is the inspection result normal?

YES

>> GO TO 5.

NO

>> Repair open circuit or short to ground or short to power in harness or connectors.

5.

CHECK ACCELERATOR PEDAL POSITION SENSOR INPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1.

Check the continuity between accelerator pedal position sensor harness connector and ECM harness

connector.

2.

Also check harness for short to ground and short to power.

Is the inspection result normal?

YES

>> GO TO 6.

NO

>> Repair open circuit or short to ground or short to power in harness or connectors.

6.

CHECK ACCELERATOR PEDAL POSITION SENSOR

EC-1359, "Component Inspection"

.

Is the inspection result normal?

YES

>> GO TO 11.

NO

>> Replace accelerator pedal position sensor.

7.

CHECK BRAKE SWITCH POWER SUPPLY CIRCUIT

1.

Turn ignition switch OFF.

2.

Disconnect stop lamp switch harness connector.

3.

Turn ignition switch ON.

4.

Check the voltage between stop lamp switch harness connector and ground.

Is the inspection result normal?

YES

>> GO TO 9.

NO

>> GO TO 8.

8.

DETECT MALFUNCTIONING PART

Check the following.

• Harness connector E105, M77

• 10A fuse (No. 11)

• Harness for open or short between fuse and stop lamp switch

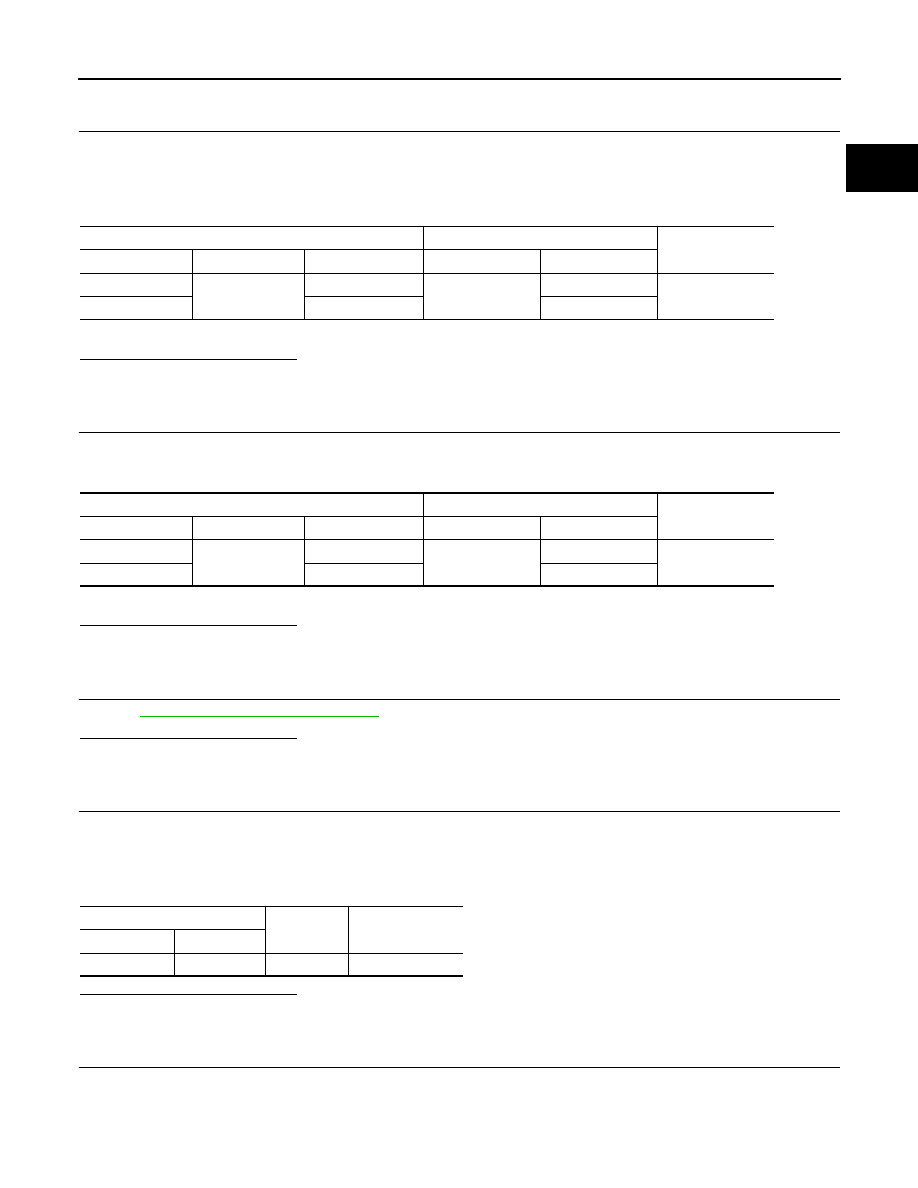

Accelerator pedal position sensor

ECM

Continuity

Sensor

Connector

Terminal

Connector

Terminal

1

E110

2

E60

127

Existed

2

1

120

Accelerator pedal position sensor

ECM

Continuity

Sensor

Connector

Terminal

Connector

Terminal

1

E110

3

E60

126

Existed

2

6

119

Stop lamp switch

Ground

Voltage

Connector

Terminal

E115

1

Ground

Battery voltage

EC-1410

< COMPONENT DIAGNOSIS >

[K9K]

P2299 ACCELERATOR/BRAKE PEDAL POSITION INCONSISTENCY

>> Repair open circuit or short to ground or short to power in harness or connectors.

9.

CHECK BRAKE SWITCH INPUT SIGNAL CIRCUIT

1.

Turn ignition switch OFF.

2.

Disconnect ECM harness connector.

3.

Check the continuity between stop lamp switch harness connector and ECM harness connector.

4.

Also check harness for short to ground and short to power.

Is the inspection result normal?

YES

>> GO TO 10.

NO

>> Repair open circuit or short to ground or short to power in harness or connectors.

10.

CHECK STOP LAMP SWITCH

EC-1359, "Component Inspection"

.

Is the inspection result normal?

YES

>> GO TO 11.

NO

>> Replace stop lamp switch.

11.

CHECK ACCELERATOR PEDAL

.

Is the inspection result normal?

YES

>> GO TO 12.

NO

>> Replace accelerator pedal position sensor.

12.

CHECK INTERMITTENT INCIDENT

GI-39, "Intermittent Incident"

>> INSPECTION END

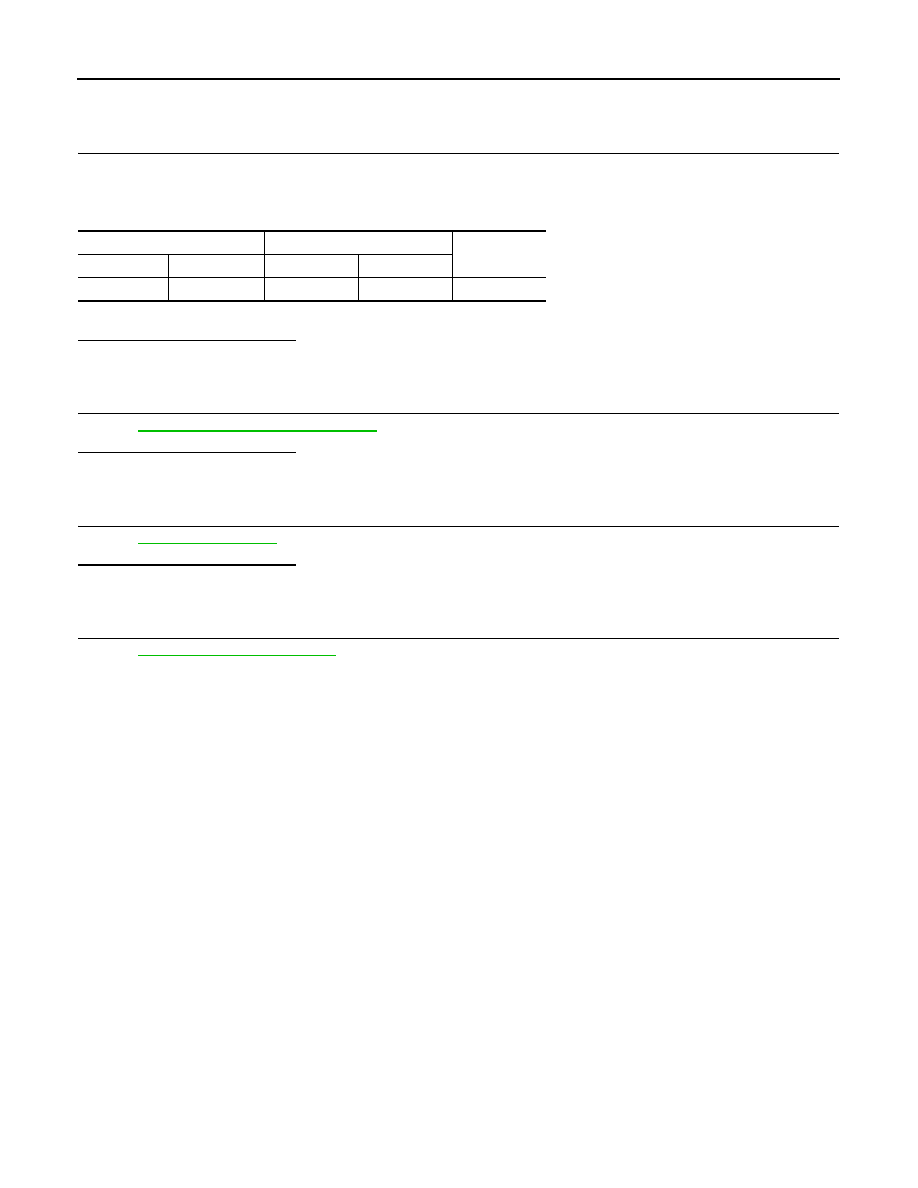

Stop lamp switch

ECM

Continuity

Connector

Terminal

Connector

Terminal

E115

2

E60

115

Existed

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст