Nissan Qashqai (2007-2010). Manual — part 460

P0335 CKP SENSOR

EC-1359

< COMPONENT DIAGNOSIS >

[K9K]

C

D

E

F

G

H

I

J

K

L

M

A

EC

N

P

O

P0335 CKP SENSOR

DTC Logic

INFOID:0000000001115076

DTC DETECTION LOGIC

NOTE:

• Conditions for applying the diagnostic procedure to the stored DTCs:

The DTC is declared present with the engine cranking or idling.

• If the DTC is present:

- Malfunction indicator (Red) lights up.

Diagnosis Procedure

INFOID:0000000000955831

1.

CHECK GROUND CONNECTIONS

1.

Turn ignition switch OFF.

2.

Check ground connection E17. Refer to Ground inspection in

Is the inspection result normal?

YES

>> GO TO 2.

NO

>> Repair or replace ground connection.

2.

CHECK CKP SENSOR GROUND CIRCUIT FOR OPEN AND SHORT

1.

Turn ignition switch OFF.

2.

Disconnect crankshaft position (CKP) sensor (1) harness connector.

3.

Disconnect ECM harness connector.

4.

Check the continuity between CKP sensor harness connector and ECM harness connector.

5.

Also check harness for short to ground and short to power.

Is the inspection result normal?

YES

>> GO TO 3.

NO

>> Repair open circuit or short to ground or short to power in harness or connectors.

3.

CHECK CKP SENSOR INPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1.

Check the continuity between CKP sensor harness connector and ECM harness connector.

2.

Also check harness for short to ground and short to power.

Is the inspection result normal?

YES

>> GO TO 4.

NO

>> Repair open circuit or short to ground or short to power in harness or connectors.

4.

CHECK CKP SENSOR

EC-1364, "Component Inspection"

.

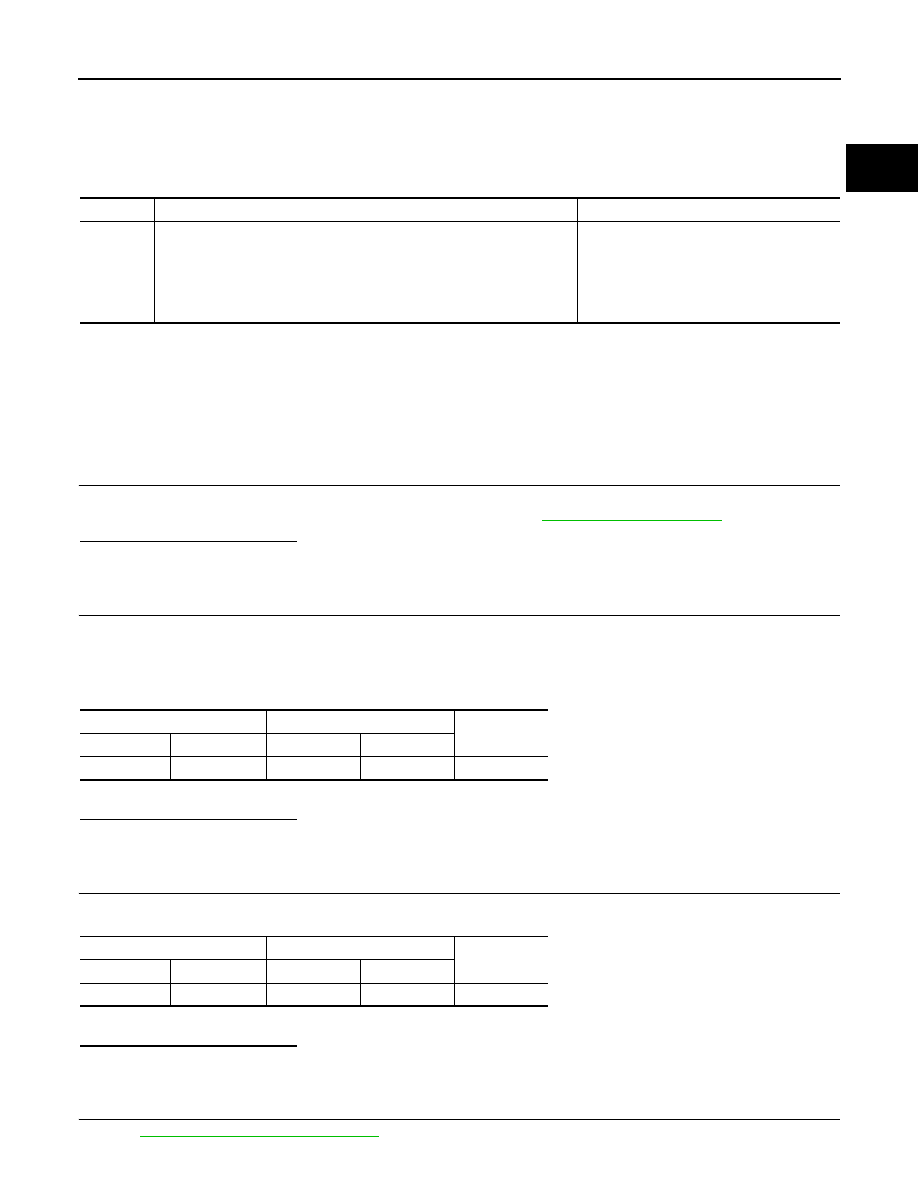

DTC No.

Trouble diagnosis name

Possible cause

P0335

CRANKSHAFT POSITION SENSOR CIRCUIT

• 1.DEF: Signal incoherence

• 2.DEF: No signal

• 3.DEF: Signal out side level

• 4.DEF: Value out side level

• 5.DEF: Configuration/ initialisation

• Harness or connectors

(The sensor circuit is open or shorted.)

• Crankshaft position sensor

• Signal plate

CKP sensor

ECM

Continuity

Connector

Terminal

Connector

Terminal

F89

2

F68

88

Existed

CKP sensor

ECM

Continuity

Connector

Terminal

Connector

Terminal

F89

1

F68

84

Existed

EC-1360

< COMPONENT DIAGNOSIS >

[K9K]

P0335 CKP SENSOR

Is the inspection result normal?

YES

>> GO TO 5.

NO

>> Replace crankshaft position sensor.

5.

CHECK GEAR TOOTH

Visually check for chipping flywheel gear tooth.

Is the inspection result normal?

YES

>> GO TO 6.

NO

>> Replace signal plate.

6.

CHECK INTERMITTENT INCIDENT

GI-39, "Intermittent Incident"

>> INSPECTION END

Component Inspection

INFOID:0000000000955832

1.

CHECK CKP SENSOR

1.

Turn ignition switch OFF.

2.

Disconnect CKP sensor harness connector.

3.

Check resistance between CKP sensor terminals as follows.

Is the inspection result normal?

YES

>> INSPECTION END

NO

>> Replace CKP sensor.

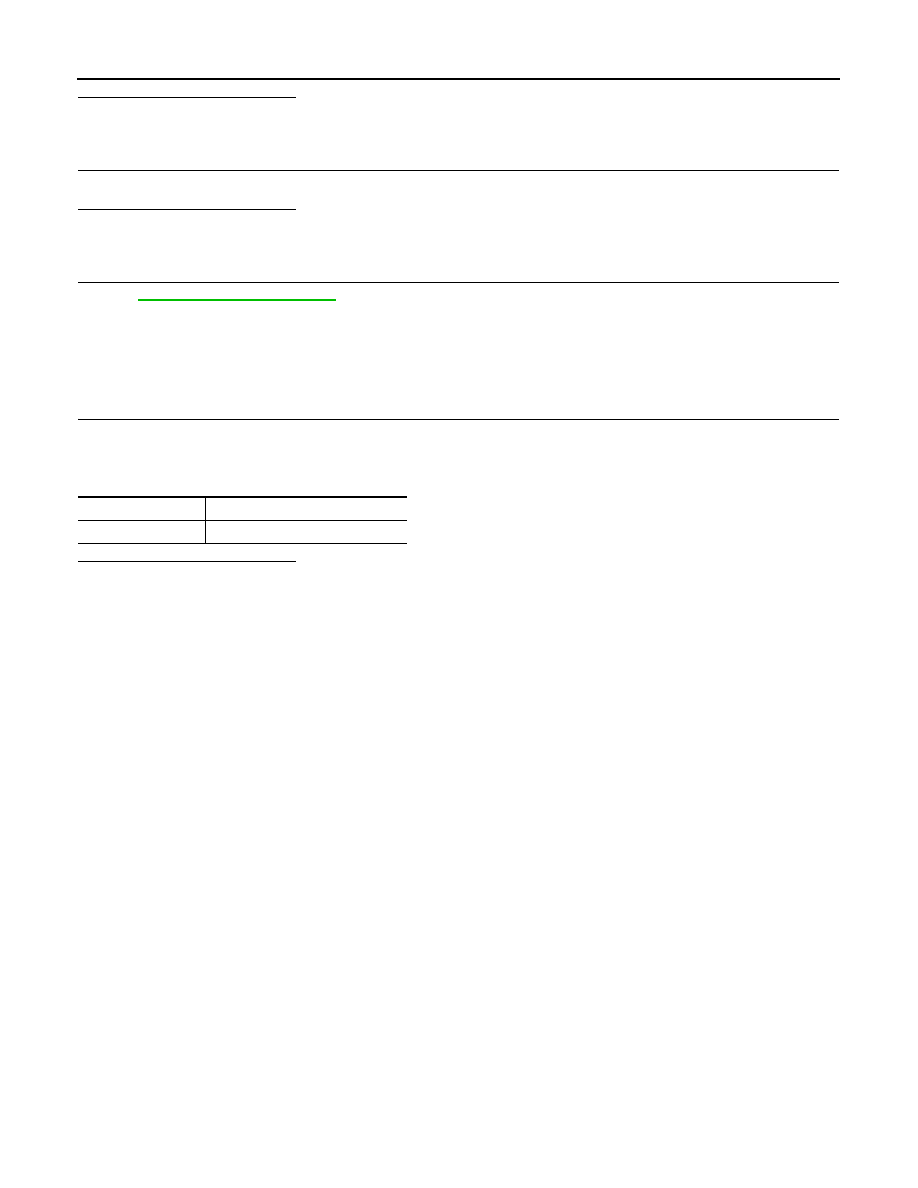

Terminals

Resistance

1 and 2

612 - 748

Ω

P0340 CMP SENSOR

EC-1361

< COMPONENT DIAGNOSIS >

[K9K]

C

D

E

F

G

H

I

J

K

L

M

A

EC

N

P

O

P0340 CMP SENSOR

DTC Logic

INFOID:0000000001115077

DTC DETECTION LOGIC

NOTE:

• Conditions for applying the diagnostic procedure to the stored DTCs:

The DTC is declared present after the engine is started or following a load test.

• Special note:

Longer starting time, requires several attempts to start the vehicle.

Diagnosis Procedure

INFOID:0000000000955836

1.

CHECK GROUND CONNECTIONS

1.

Turn ignition switch OFF.

2.

Check ground connection E17. Refer to Ground inspection in

Is the inspection result normal?

YES

>> GO TO 2.

NO

>> Repair or replace ground connection.

2.

CHECK CMP SENSOR POWER SUPPLY CIRCUIT

1.

Turn ignition switch OFF.

2.

Disconnect camshaft position (CMP) sensor harness connector.

3.

Turn ignition switch ON.

4.

Check the voltage between CMP sensor harness connector and ground.

Is the inspection result normal?

YES

>> GO TO 4.

NO

>> GO TO 3.

3.

DETECT MALFUNCTIONING PART

Check the following.

• Harness connector E7, F121

• Harness for open or short between ECM and CMP sensor

• Harness for open or short between IPDM E/R and CMP sensor

>> Repair open circuit or short to ground or short to power in harness or connectors.

4.

CHECK CMP SENSOR GROUND CIRCUIT FOR OPEN AND SHORT

1.

Turn ignition switch OFF.

2.

Disconnect ECM harness connector.

3.

Check the continuity between CMP sensor harness connector and ECM harness connector.

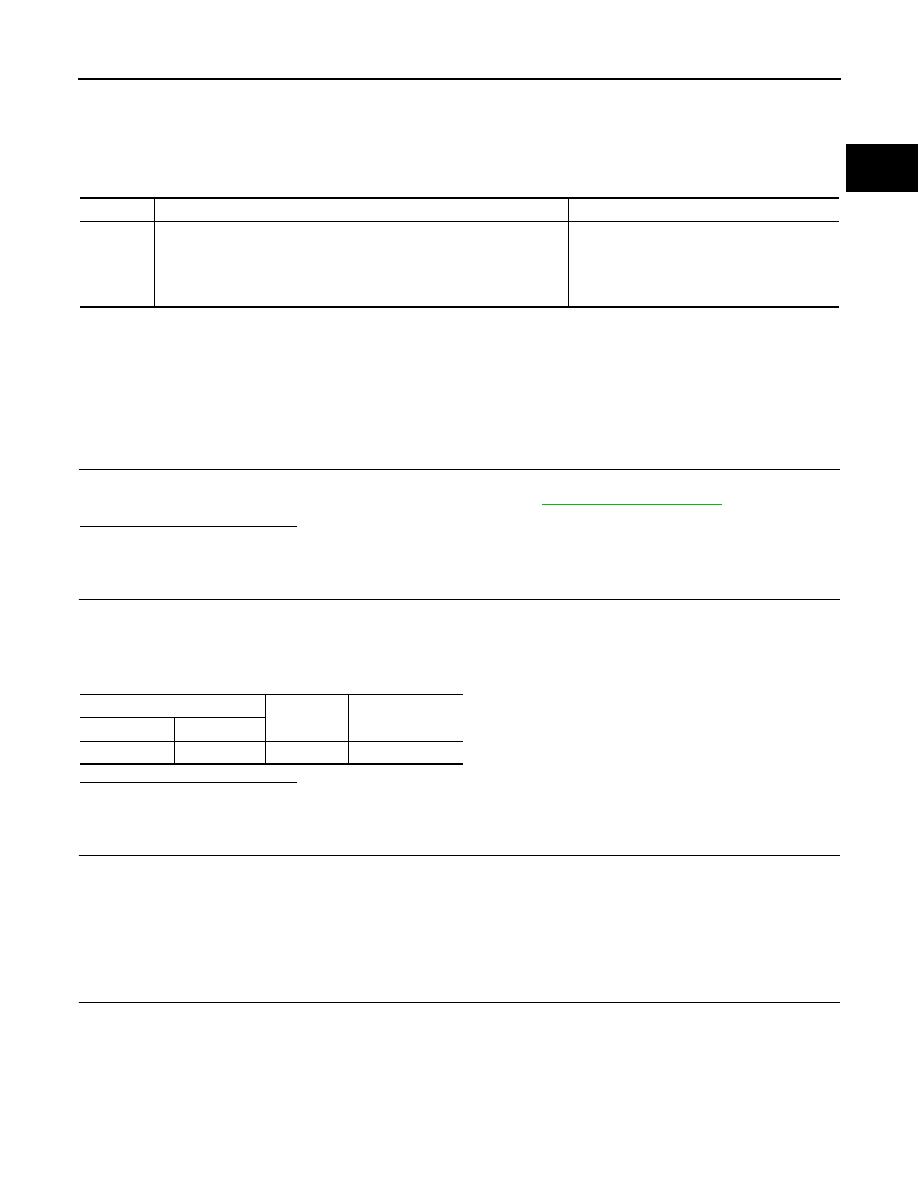

DTC No.

Trouble diagnosis name

Possible cause

P0340

CAMSHAFT POSITION SENSOR CIRCUIT

• 1.DEF: Signal incoherence

• 2.DEF: No signal

• 3.DEF: Value out side level

• 4.DEF: Configuration/ initialisation

• Harness or connectors

(The sensor circuit is open or shorted.)

• Camshaft position sensor

• Timing belt

• Signal plate

CMP sensor

Ground

Voltage

Connector

Terminal

F87

3

Ground

Battery voltage

EC-1362

< COMPONENT DIAGNOSIS >

[K9K]

P0340 CMP SENSOR

4.

Also check harness for short to ground and short to power.

Is the inspection result normal?

YES

>> GO TO 5.

NO

>> Repair open circuit or short to ground or short to power in harness or connectors.

5.

CHECK CMP SENSOR INPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1.

Check the continuity between CMP sensor harness connector and ECM harness connector.

2.

Also check harness for short to ground and short to power.

Is the inspection result normal?

YES

>> GO TO 6.

NO

>> Repair open circuit or short to ground or short to power in harness or connectors.

6.

CHECK CMP SENSOR

EC-1364, "Component Inspection"

.

Is the inspection result normal?

YES

>> GO TO 7.

NO

>> Replace camshaft position sensor.

7.

CHECK SPROCKET

Visually check for chipping signal plate gear tooth.

Is the inspection result normal?

YES

>> GO TO 8.

NO

>> Repair or replace sprocket.

8.

CHECK TIMING BELT

Is the inspection result normal?

YES

>> GO TO 9.

NO

>> Replace timing belt.

9.

CHECK INTERMITTENT INCIDENT

GI-39, "Intermittent Incident"

>> INSPECTION END

Component Inspection

INFOID:0000000000955837

1.

CHECK CMP SENSOR

1.

Reconnect all harness connectors disconnected.

2.

Start engine and warm it up to normal operating temperature.

3.

Measure the voltage signal between ECM harness connector and ground under the following conditions.

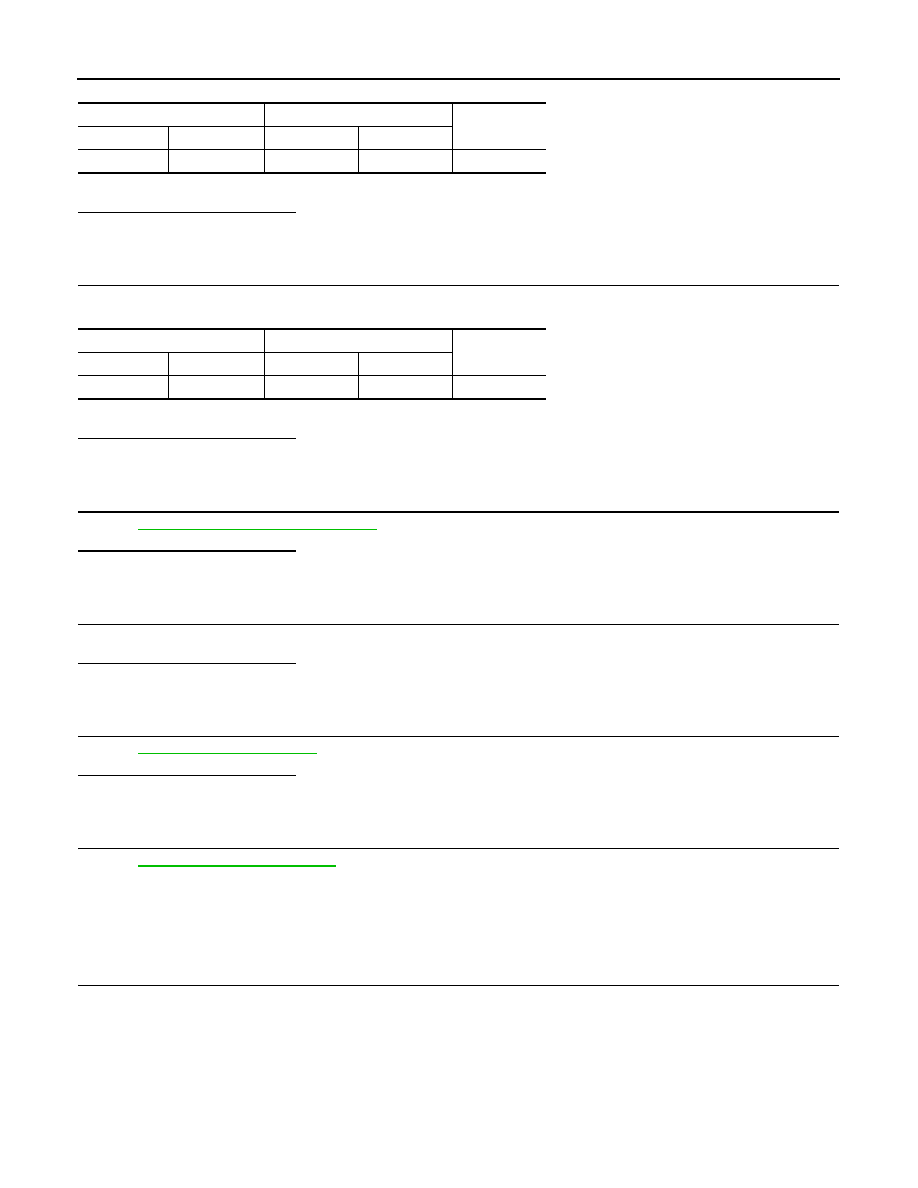

CMP sensor

ECM

Continuity

Connector

Terminal

Connector

Terminal

F87

1

F68

65

Existed

CMP sensor

ECM

Continuity

Connector

Terminal

Connector

Terminal

F87

2

F68

75

Existed

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст