Nissan Qashqai (2007-2010). Manual — part 168

P0327, P0328 KS

EC-191

< COMPONENT DIAGNOSIS >

[HR16DE (WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

M

A

EC

N

P

O

P0327, P0328 KS

Description

INFOID:0000000001056294

The knock sensor is attached to the cylinder block. It senses engine knocking using a piezoelectric element. A

knocking vibration from the cylinder block is sensed as vibrational pressure. This pressure is converted into a

voltage signal and sent to the ECM.

DTC Logic

INFOID:0000000001056295

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.

PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

TESTING CONDITION:

Before performing the following procedure, confirm that battery voltage is more than 10V at idle.

>> GO TO 2.

2.

PERFORM DTC CONFIRMATION PROCEDURE

1.

Start engine and run it for at least 5 seconds at idle speed.

2.

Check 1st trip DTC.

Is 1st trip DTC detected?

YES

>> Go to

NO

>> INSPECTION END

Diagnosis Procedure

INFOID:0000000001056296

1.

CHECK GROUND CONNECTION

1.

Turn ignition switch OFF.

2.

Check ground connection E21. Refer to Ground Inspection in

.

Is the inspection result normal?

YES

>> GO TO 2.

NO

>> Repair or replace ground connection.

2.

CHECK KNOCK SENSOR GROUND CIRCUIT FOR OPEN AND SHORT

1.

Disconnect knock sensor harness connector and disconnect ECM harness connector.

2.

Check the continuity between knock sensor harness connector and ECM harness connector.

3.

Also check harness for short to ground and short to power.

Is the inspection result normal?

YES

>> GO TO 3.

NO

>> Repair open circuit or short to ground or short to power in harness or connectors.

DTC No.

Trouble diagnosis

name

DTC detected condition

Possible cause

P0327

Knock sensor circuit

low input

An excessively low voltage from the sensor is

sent to ECM.

• Harness or connectors

(The sensor circuit is open or shorted.)

• Knock sensor

P0328

Knock sensor circuit

high input

An excessively high voltage from the sensor is

sent to ECM.

Knock sensor

ECM

Continuity

Connector

Terminal

Connector

Terminal

F12

2

F8

40

Existed

EC-192

< COMPONENT DIAGNOSIS >

[HR16DE (WITH EURO-OBD)]

P0327, P0328 KS

3.

CHECK KNOCK SENSOR INPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1.

Check the continuity between knock sensor harness connector and ECM harness connector.

2.

Also check harness for short to ground and short to power.

Is the inspection result normal?

YES

>> GO TO 4.

NO

>> Repair open circuit or short to ground or short to power in harness or connectors.

4.

CHECK KNOCK SENSOR

EC-192, "Component Inspection"

Is the inspection result normal?

YES

>> GO TO 5.

NO

>> Replace knock sensor.

5.

CHECK INTERMITTENT INCIDENT

GI-39, "Intermittent Incident"

>> INSPECTION END

Component Inspection

INFOID:0000000001056297

1.

CHECK KNOCK SENSOR

1.

Turn ignition switch OFF.

2.

Disconnect knock sensor harness connector.

3.

Check resistance between knock sensor terminals as follows.

NOTE:

It is necessary to use an ohmmeter which can measure more than 10 M

Ω

.

CAUTION:

Do not use any knock sensors that have been dropped or physically damaged. Use only new ones.

Is the inspection result normal?

YES

>> INSPECTION END

NO

>> Replace knock sensor.

Knock sensor

ECM

Continuity

Connector

Terminal

Connector

Terminal

F12

1

F8

37

Existed

Terminals

Resistance [at 20

°

C (68

°

F)]

1 and 2

Approx. 532 - 588 k

Ω

P0335 CKP SENSOR (POS)

EC-193

< COMPONENT DIAGNOSIS >

[HR16DE (WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

M

A

EC

N

P

O

P0335 CKP SENSOR (POS)

Description

INFOID:0000000001056298

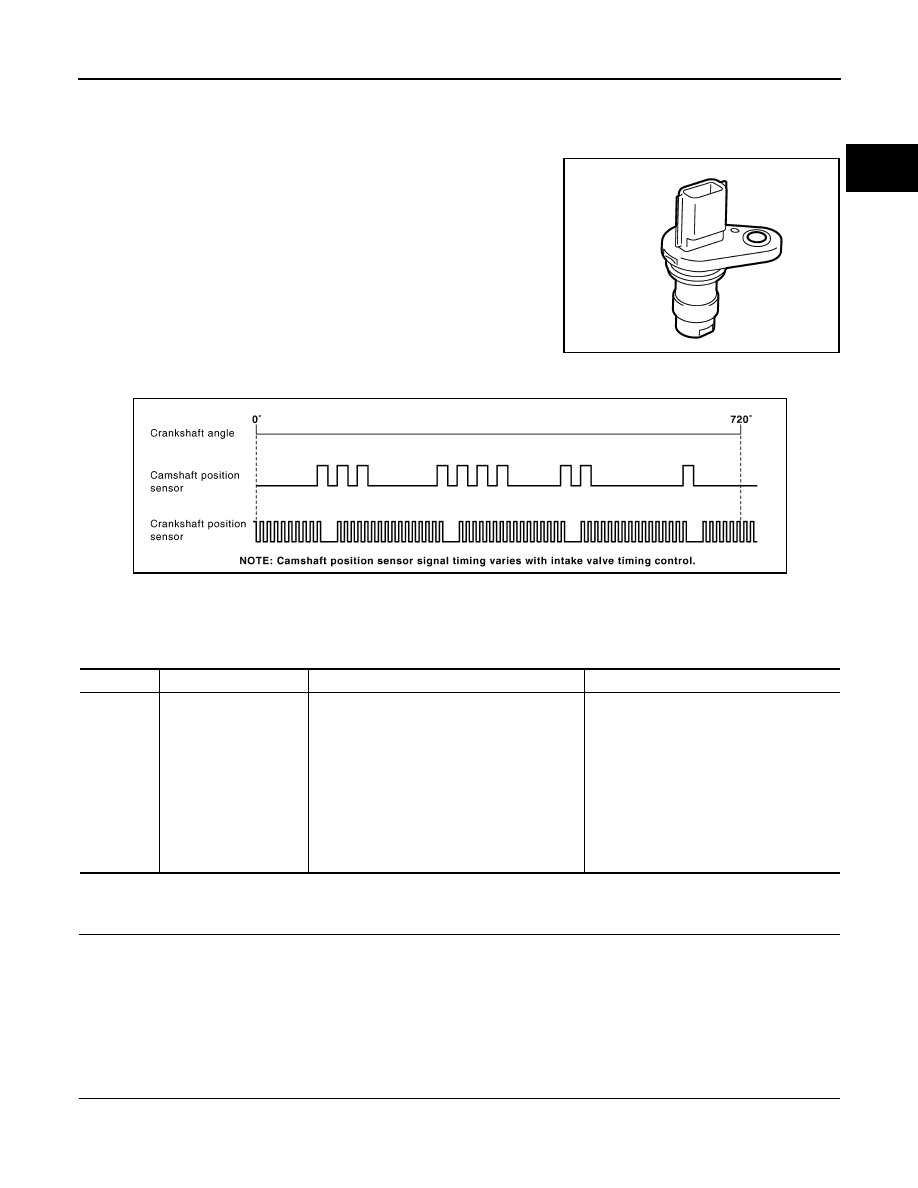

The crankshaft position sensor (POS) is located on the cylinder

block rear housing facing the gear teeth (cogs) of the signal plate at

end of the crankshaft. It detects the fluctuation of the engine revolu-

tion.

The sensor consists of a permanent magnet and Hall IC.

When the engine is running, the high and low parts of the teeth

cause the gap with the sensor to change.

The changing gap causes the magnetic field near the sensor to

change.

Due to the changing magnetic field, the voltage from the sensor

changes.

The ECM receives the voltage signal and detects the fluctuation of

the engine revolution.

ECM receives the signals as shown in the figure.

DTC Logic

INFOID:0000000001056299

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.

PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

TESTING CONDITION:

Before performing the following procedure, confirm that battery voltage is more than 10.5V with igni-

tion switch ON.

>> GO TO 2.

2.

PERFORM DTC CONFIRMATION PROCEDURE

1.

Start engine and let it idle for at least 5 seconds.

If engine does not start, crank engine for at least 2 seconds.

PBIA9209J

PBIB2382E

DTC No.

Trouble diagnosis name

DTC detecting condition

Possible cause

P0335

Crankshaft position sen-

sor (POS) circuit

• The crankshaft position sensor (POS) signal

is not detected by the ECM during the first

few seconds of engine cranking.

• The proper pulse signal from the crankshaft

position sensor (POS) is not sent to ECM

while the engine is running.

• The crankshaft position sensor (POS) signal

is not in the normal pattern during engine run-

ning.

• Harness or connectors

[Crankshaft position sensor (POS) circuit

is open or shorted.]

(Refrigerant pressure sensor circuit is

shorted.)

(Accelerator pedal position sensor circuit

is shorted.)

• Crankshaft position sensor (POS)

• Refrigerant pressure sensor

• Accelerator pedal position sensor

• Signal plate

EC-194

< COMPONENT DIAGNOSIS >

[HR16DE (WITH EURO-OBD)]

P0335 CKP SENSOR (POS)

2.

Check 1st trip DTC.

Is 1st trip DTC detected?

YES

>> Go to

NO

>> INSPECTION END

Diagnosis Procedure

INFOID:0000000001056300

1.

CHECK GROUND CONNECTION

1.

Turn ignition switch OFF.

2.

Check ground connection E21. Refer to Ground Inspection in

.

Is the inspection result normal?

YES

>> GO TO 2.

NO

>> Repair or replace ground connection.

2.

CHECK CRANKSHAFT POSITION (CKP) SENSOR (POS) POWER SUPPLY CIRCUIT-I

1.

Disconnect crankshaft position (CKP) sensor (POS) harness connector.

2.

Turn ignition switch ON.

3.

Check the voltage between CKP sensor (POS) harness connector and ground.

Is the inspection result normal?

YES

>> GO TO 8.

NO

>> GO TO 3.

3.

CHECK CRANKSHAFT POSITION (CKP) SENSOR (POS) POWER SUPPLY CIRCUIT-II

1.

Turn ignition switch OFF.

2.

Disconnect ECM harness connector.

3.

Check the continuity between CKP sensor (POS) harness connector and ECM harness connector.

Is the inspection result normal?

YES

>> GO TO 4.

NO

>> Repair open circuit.

4.

CHECK CRANKSHAFT POSITION (CKP) SENSOR (POS) POWER SUPPLY CIRCUIT-III

Check harness for short to power and short to ground, between the following terminals.

Is the inspection result normal?

YES

>> GO TO 5.

NO

>> Repair short to ground or short to power in harness or connectors.

5.

CHECK COMPONENTS

Check the following.

• Refrigerant pressure sensor (Refer to

HAC-161, "Component Inspection"

CKP sensor (POS)

Ground

Voltage

Connector

Terminal

F20

1

Ground

Approx. 5V

CKP sensor (POS)

ECM

Continuity

Connector

Terminal

Connector

Terminal

F20

1

F8

75

Existed

ECM

Sensor

Connector

Terminal

Name

Connector

Terminal

F8

74

Refrigerant pressure sensor

E49

3

75

CKP sensor (POS)

F20

1

E16

102

APP sensor

E110

5

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст