Nissan Qashqai (2007-2010). Manual — part 890

HA-130

< ON-VEHICLE MAINTENANCE >

[MANUAL AIR CONDITIONER (HR/MR)]

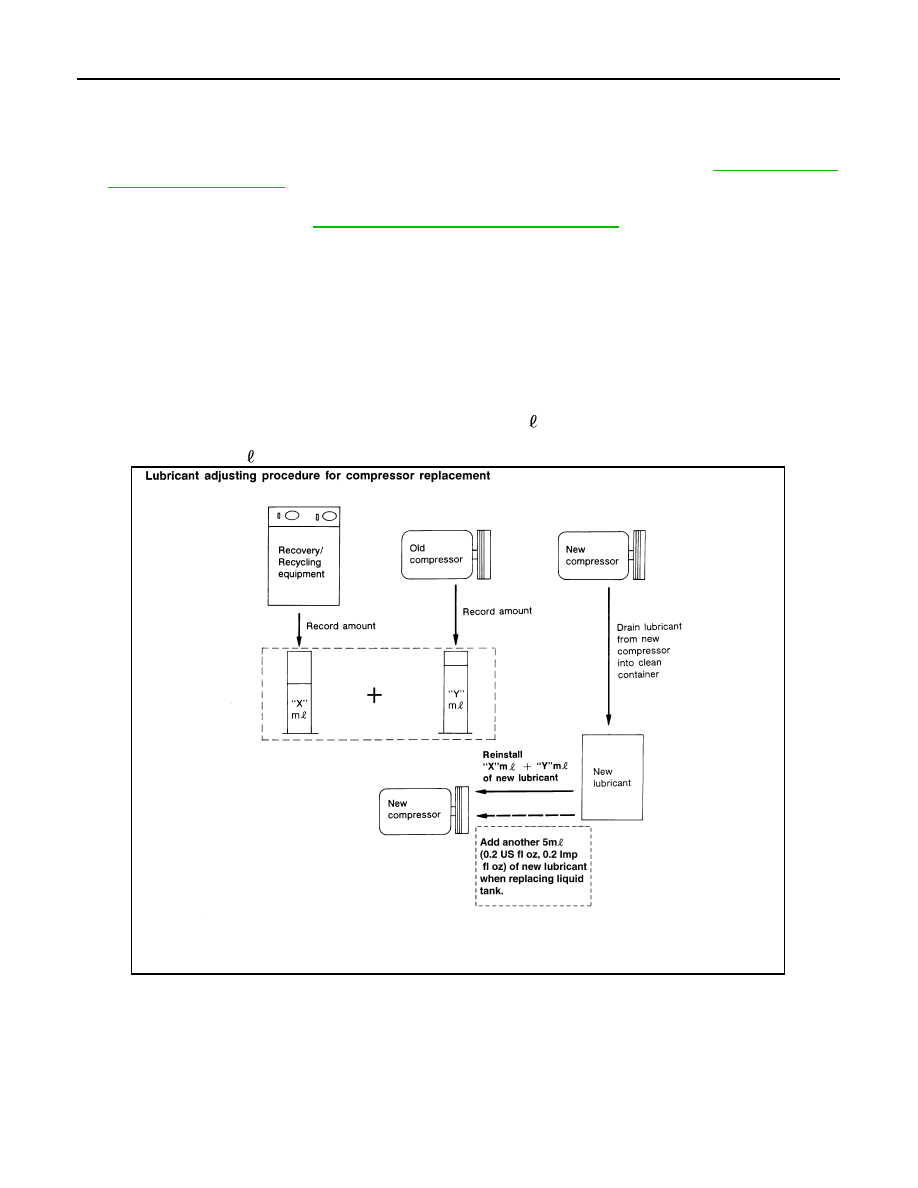

LUBRICANT

1.

Before connecting recovery/recycling recharging equipment to vehicle, check recovery/recycling recharg-

ing equipment gauges. No refrigerant pressure should be displayed. If NG, recover refrigerant from equip-

ment lines.

2.

Connect recovery/recycling recharging equipment to vehicle. Confirm refrigerant purity in supply tank

using recovery/recycling recharging equipment and refrigerant identifier. If NG, refer to

3.

Confirm refrigerant purity in vehicle A/C system using recovery/recycling recharging equipment and refrig-

erant identifier. If NG, refer to

HA-170, "Working with HFC-134a (R-134a)"

4.

Discharge refrigerant into the refrigerant recovery/recycling equipment. Measure lubricant discharged into

the recovery/recycling equipment.

5.

Drain the lubricant from the old (removed) compressor into a graduated container and recover the amount

of lubricant drained.

6.

Drain the lubricant from the new compressor into a separate, clean container.

7.

Measure an amount of new lubricant installed equal to amount drained from old compressor. Add this

lubricant to new compressor through the suction port opening.

8.

Measure an amount of new lubricant equal to the amount recovered during discharging. Add this lubricant

to new compressor through the suction port opening.

9.

If the liquid tank also needs to be replaced, add another 5 m (0.2 US fl oz., 0.2 Imp fl oz.) of lubricant at

this time.

Do not add this 5 m (0.2 US fl oz., 0.2 Imp fl oz.) of lubricant when replaces the compressor only.

RJIA3578E

REFRIGERATION SYSTEM

HA-131

< ON-VEHICLE MAINTENANCE >

[MANUAL AIR CONDITIONER (HR/MR)]

C

D

E

F

G

H

J

K

L

M

A

B

HA

N

O

P

REFRIGERATION SYSTEM

Inspection

INFOID:0000000001098156

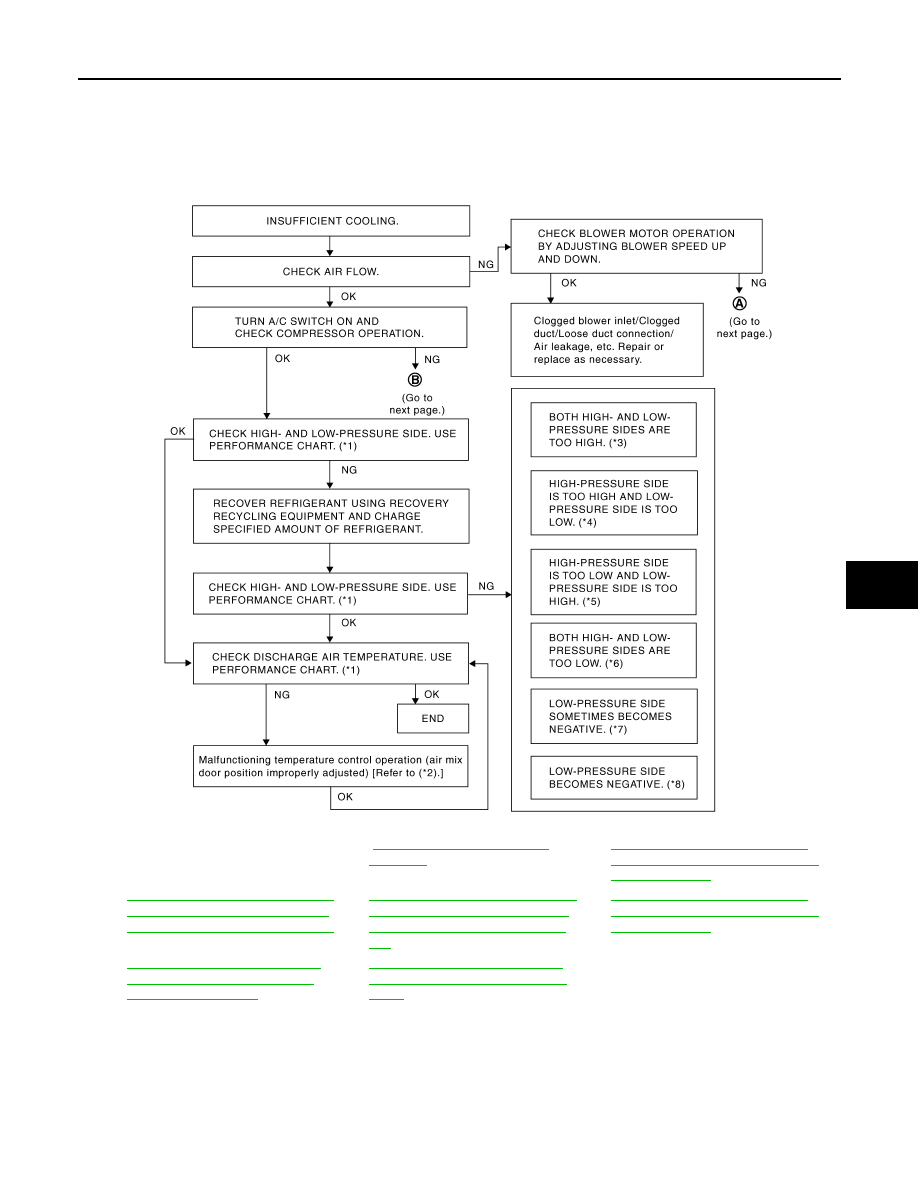

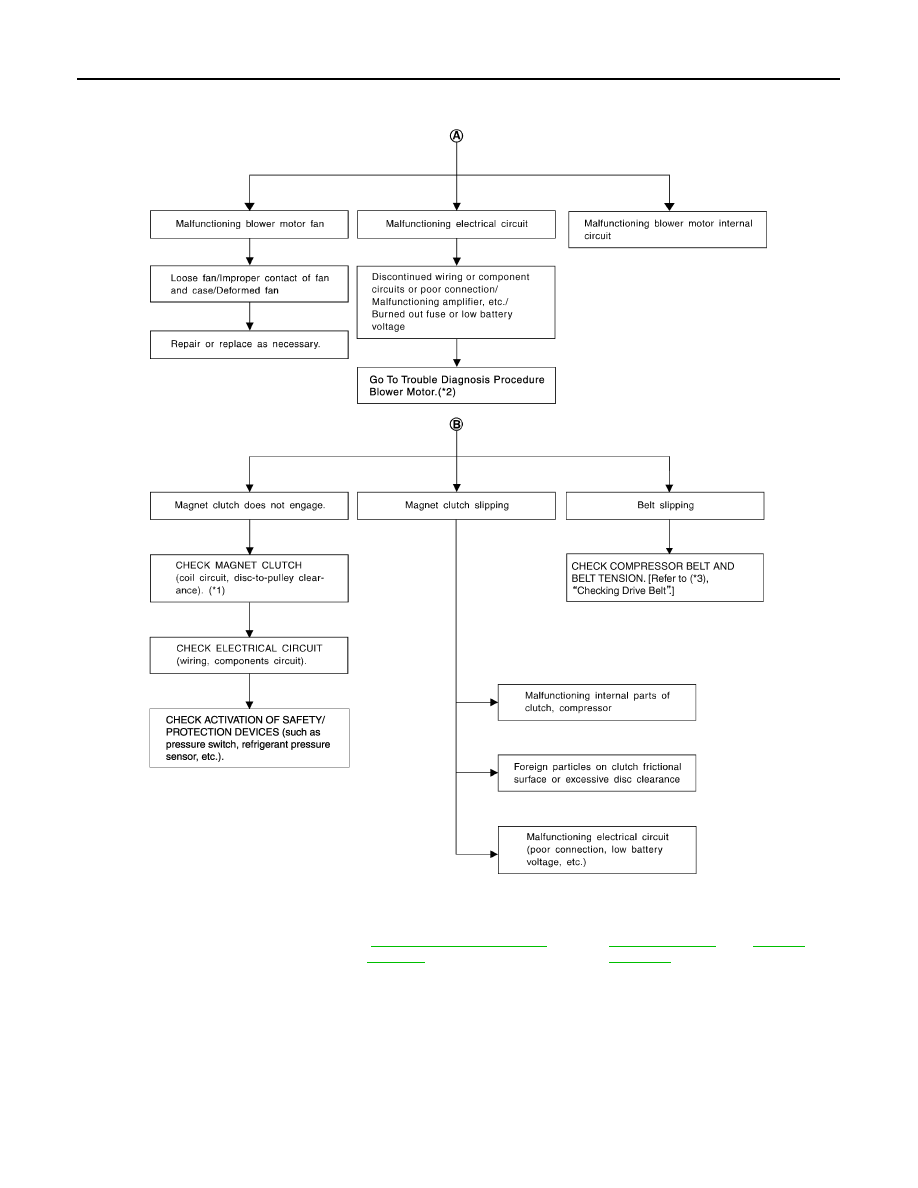

PERFORMANCE TEST DIAGNOSIS

*2

*3

HA-165, "BOTH HIGH- AND LOW-

PRESSURE SIDES ARE TOO HIGH

: Symptom Table"

*4

HA-165, "HIGH-PRESSURE SIDE IS

TOO HIGH AND LOW-PRESSURE

SIDE IS TOO LOW : Symptom Table"

*5

HA-166, "HIGH-PRESSURE SIDE IS

TOO LOW AND LOW-PRESSURE

SIDE IS TOO HIGH : Symptom Ta-

ble"

*6

HA-166, "BOTH HIGH- AND LOW-

PRESSURE SIDES ARE TOO LOW

: Symptom Table"

*7

HA-167, "LOW-PRESSURE SIDE

SOMETIMES BECOMES NEGA-

TIVE : Symptom Table"

*8

HA-167, "LOW-PRESSURE SIDE

BECOMES NEGATIVE : Symptom

Table"

JSIIA0130GB

HA-132

< ON-VEHICLE MAINTENANCE >

[MANUAL AIR CONDITIONER (HR/MR)]

REFRIGERATION SYSTEM

Refrigerant Leaks

INFOID:0000000001098158

Perform a visual inspection of all refrigeration parts, fittings, hoses and components for signs of A/C lubricant

leakage, damage and corrosion. A/C lubricant leakage may indicate an area of refrigerant leakage. Allow

extra inspection time in these areas when using either an electrical leak detector or fluorescent dye leak

detector (SST: J-42220).

If dye is observed, confirm the leak with an electrical leak detector. It is possible a prior leak was repaired and

not properly cleaned.

*2

*3

(MR)

SJIA1642E

REFRIGERATION SYSTEM

HA-133

< ON-VEHICLE MAINTENANCE >

[MANUAL AIR CONDITIONER (HR/MR)]

C

D

E

F

G

H

J

K

L

M

A

B

HA

N

O

P

When searching for leaks, do not stop when one leak is found but continue to check for additional leaks at all

system components and connections.

When searching for refrigerant leaks using an electrical leak detector, move the probe along the suspected

leak area at 1 to 2 inches per second and no further than 1/4 inch from the component.

CAUTION:

Moving the electrical leak detector probe slower and closer to the suspected leak area will improve the

chances of finding a leak.

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст