Nissan Qashqai (2007-2010). Manual — part 542

SERVICE DATA AND SPECIFICATIONS (SDS)

TM-103

< SERVICE DATA AND SPECIFICATIONS (SDS)

[6MT: RS6F94R]

C

E

F

G

H

I

J

K

L

M

A

B

TM

N

O

P

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

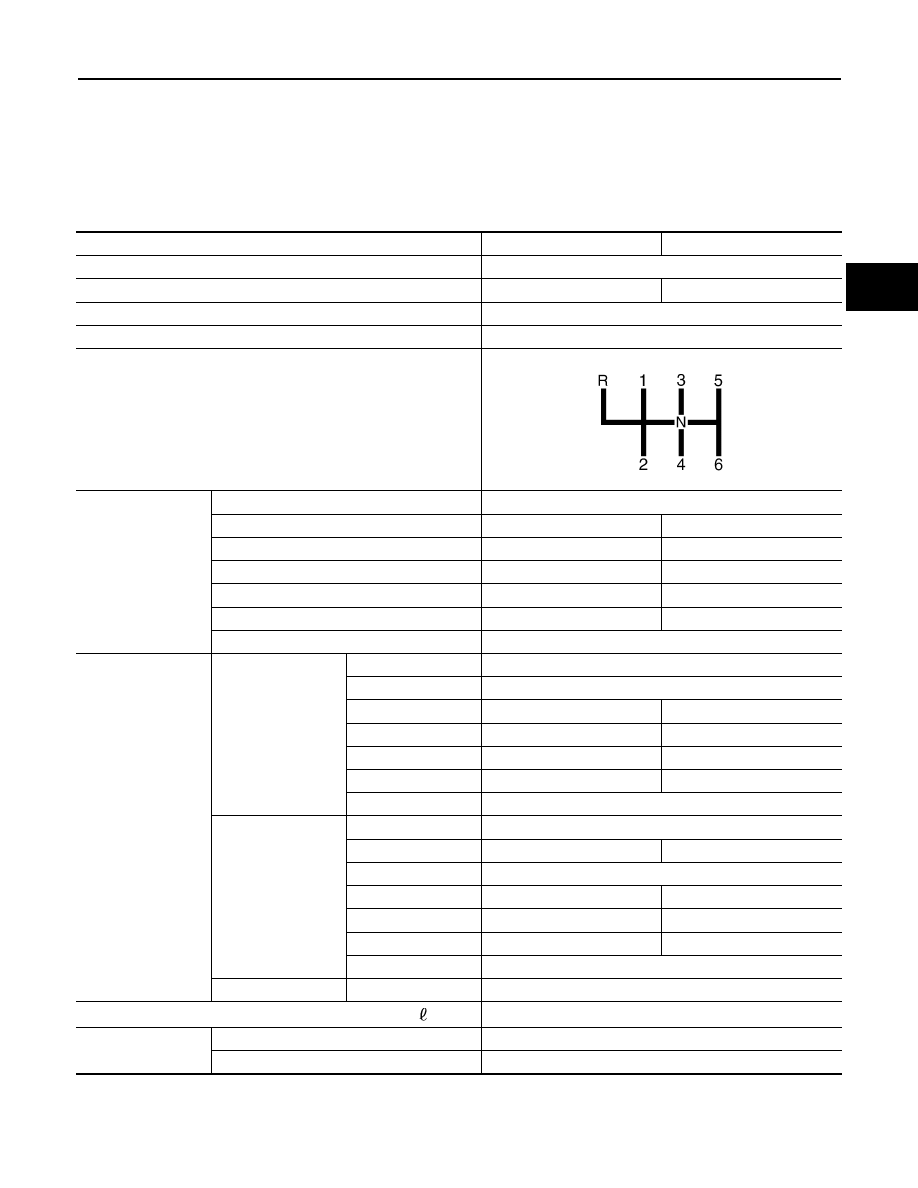

General Specification

INFOID:0000000001043094

TRANSAXLE

FINAL GEAR

Engine type

MR20DE

K9K

Transaxle model

RS6F94R

Model code number

JD200

JD500

Number of speeds

6

Synchromesh type

Warner

Shift pattern

Gear ratio

1st

3.7273

2nd

2.1053

1.9474

3rd

1.5185

1.3226

4th

1.1714

0.975

5th

0.9143

0.7632

6th

0.7674

0.6383

Reverse

3.6865

Number of teeth

Input gear

1st

11

2nd

19

3rd

27

31

4th

35

40

5th

35

38

6th

43

47

Reverse

11

Main gear

1st

41

2nd

40

37

3rd

41

4th

41

39

5th

32

29

6th

33

30

Reverse

42

Reverse idler gear

Input/Output

28/29

Oil capacity

(Imp pt)

Approx. 2.0 (3-1/2)

Remarks

Reverse synchronizer

Installed

Triple-cone synchronizer

1st and 2nd

PCIB1769E

TM-104

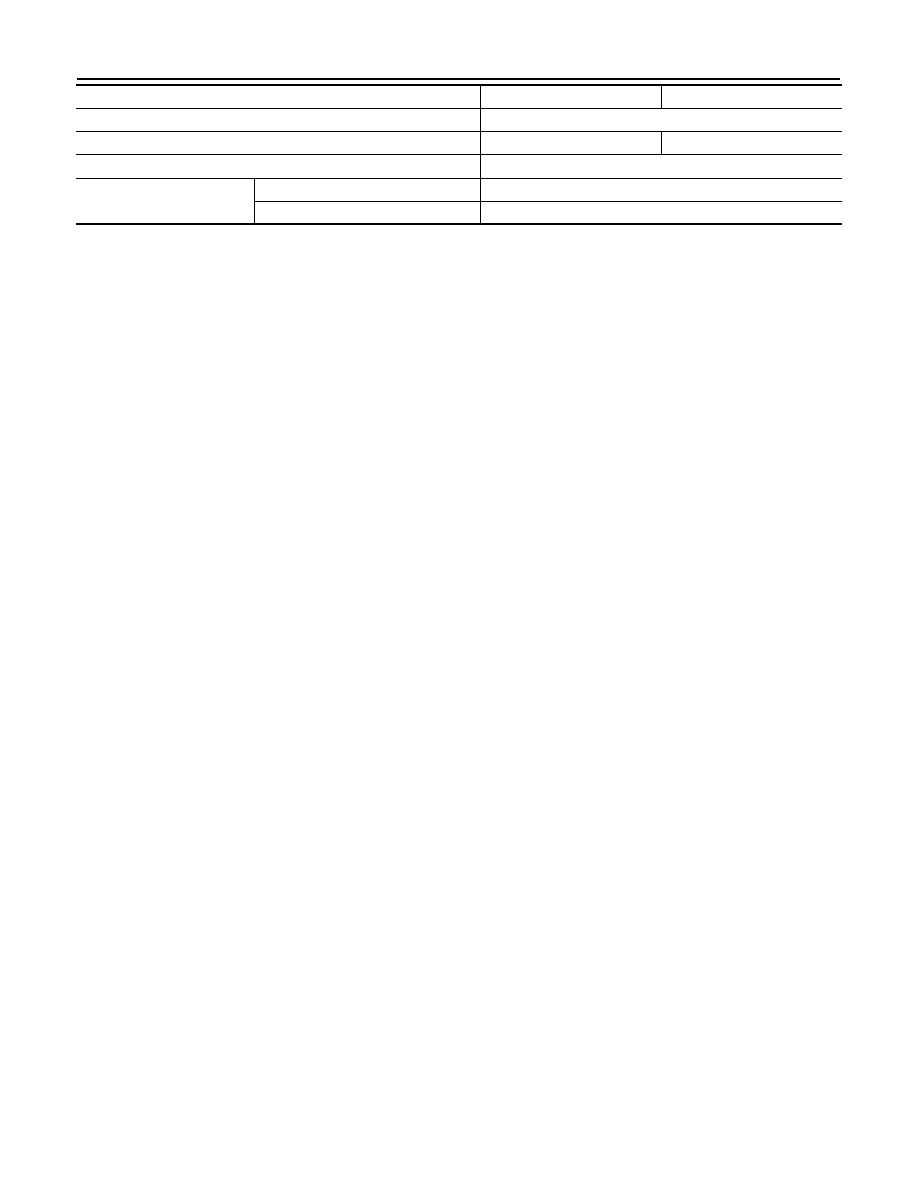

< SERVICE DATA AND SPECIFICATIONS (SDS)

[6MT: RS6F94R]

SERVICE DATA AND SPECIFICATIONS (SDS)

Engine type

MR20DE

K9K

Transaxle model

RS6F94R

Model code number

JD200

JD500

Final gear ratio

4.4375

Number of teeth

Final gear/Pinion

71/16

Side gear/Pinion mate gear

13/10

M/T SYSTEM

TM-105

< FUNCTION DIAGNOSIS >

[6MT: RS6F52A]

C

E

F

G

H

I

J

K

L

M

A

B

TM

N

O

P

FUNCTION DIAGNOSIS

M/T SYSTEM

System Diagram

INFOID:0000000001034930

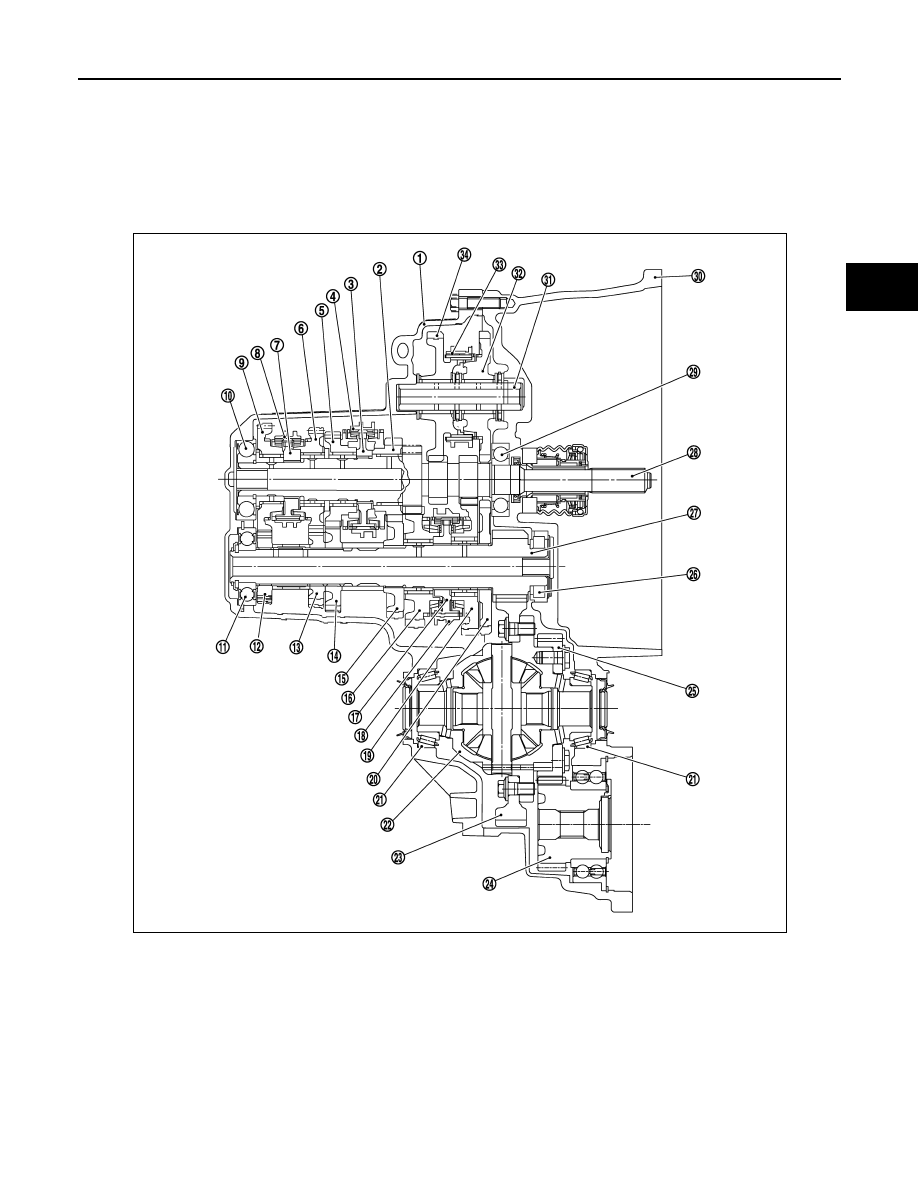

CROSS-SECTIONAL VIEW

1.

Transaxle case

2.

3rd input gear

3.

3rd-4th synchronizer hub

4.

3rd-4th coupling sleeve

5.

4th input gear

6.

5th input gear

7.

5th-6th synchronizer hub

8.

5th-6th coupling sleeve

9.

6th input gear

10. Input shaft rear bearing

11.

Mainshaft rear bearing

12. 6th main gear

13. 5th main gear

14. 4th main gear

15. 3rd main gear

16. 2nd main gear

17. 1st-2nd synchronizer hub

18. 1st-2nd coupling sleeve

19. 1st main gear

20. Reverse main gear

21. Differential side bearing

22. Differential case assembly

23. Final gear

24. Output gear assembly

25. Reduction gear

26. Mainshaft front bearing

27. Mainshaft

JPDIC0046ZZ

TM-106

< FUNCTION DIAGNOSIS >

[6MT: RS6F52A]

M/T SYSTEM

System Description

INFOID:0000000001034931

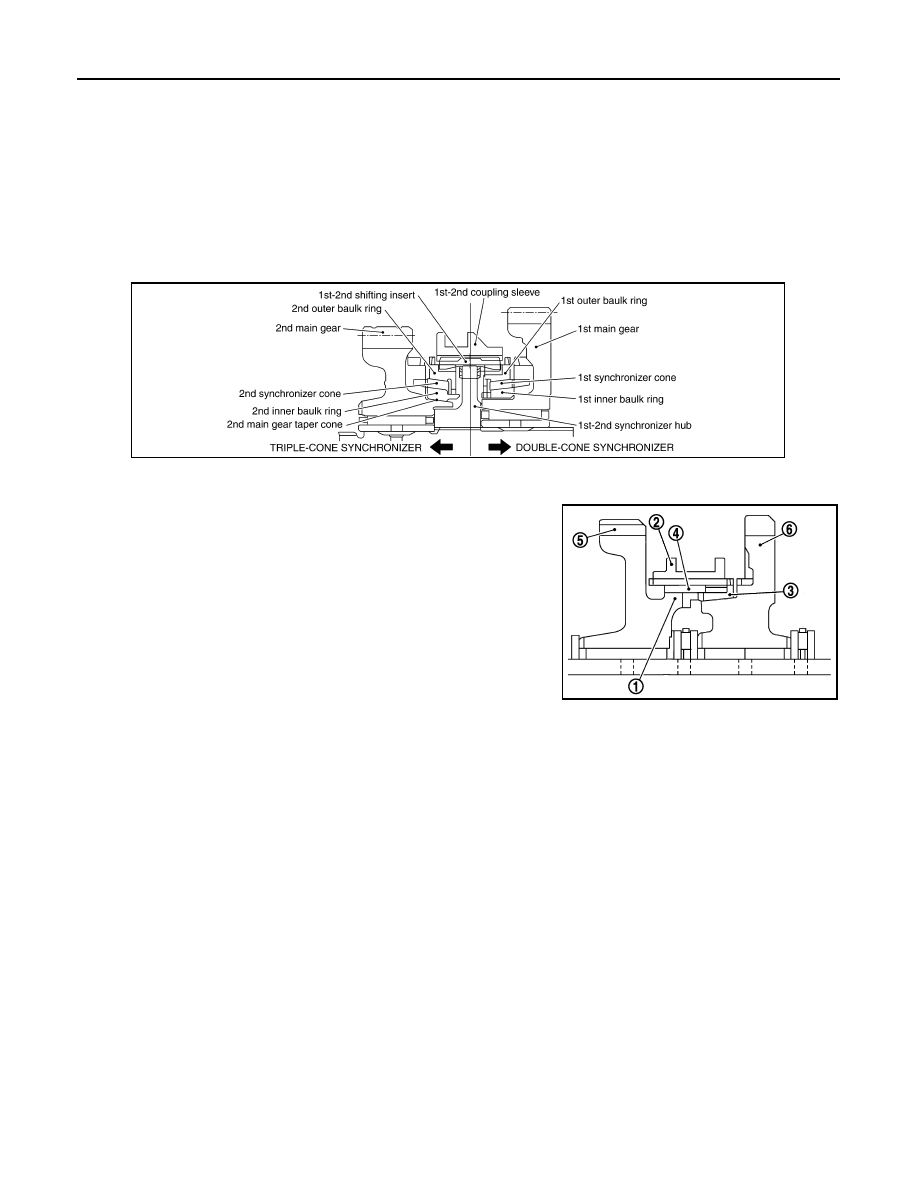

DOUBLE-CONE SYNCHRONIZER

Double-cone synchronizer are adopted for 1st and 3rd gears to reduce operating force of the control lever.

TRIPLE-CONE SYNCHRONIZER

Triple-cone synchronizer is adopted for 2nd gear to reduce operating force of the control lever.

REVERSE GEAR NOISE PREVENTION FUNCTION (SYNCHRONIZING METHOD)

Reverse gear can be matched smoothly in a structure by setting syn-

chronizer hub (1) of reverse idler gear (rear), reverse coupling

sleeve (2), reverse baulk ring (3), and reverse insert spring (4) to

reverse idler gears, and letting reverse gear be synchronized.

28. Input shaft

29. Input shaft front bearing

30. Clutch housing

31. Reverse idler shaft

32. Reverse idler gear (front)

33. Reverse coupling sleeve

34. Reverse idler gear (rear)

PCIB0774E

5

: Reverse idler gear (rear)

6

: Reverse idler gear (front)

PCIB1909E

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст