Nissan Qashqai (2007-2010). Manual — part 44

EM-124

< SERVICE DATA AND SPECIFICATIONS (SDS)

[HR16DE]

SERVICE DATA AND SPECIFICATIONS (SDS)

UNDERSIZE TABLE

Unit: mm (in)

CONNECTING ROD BEARING OIL CLEARANCE

Unit: mm (in)

Main Bearing

INFOID:0000000000893905

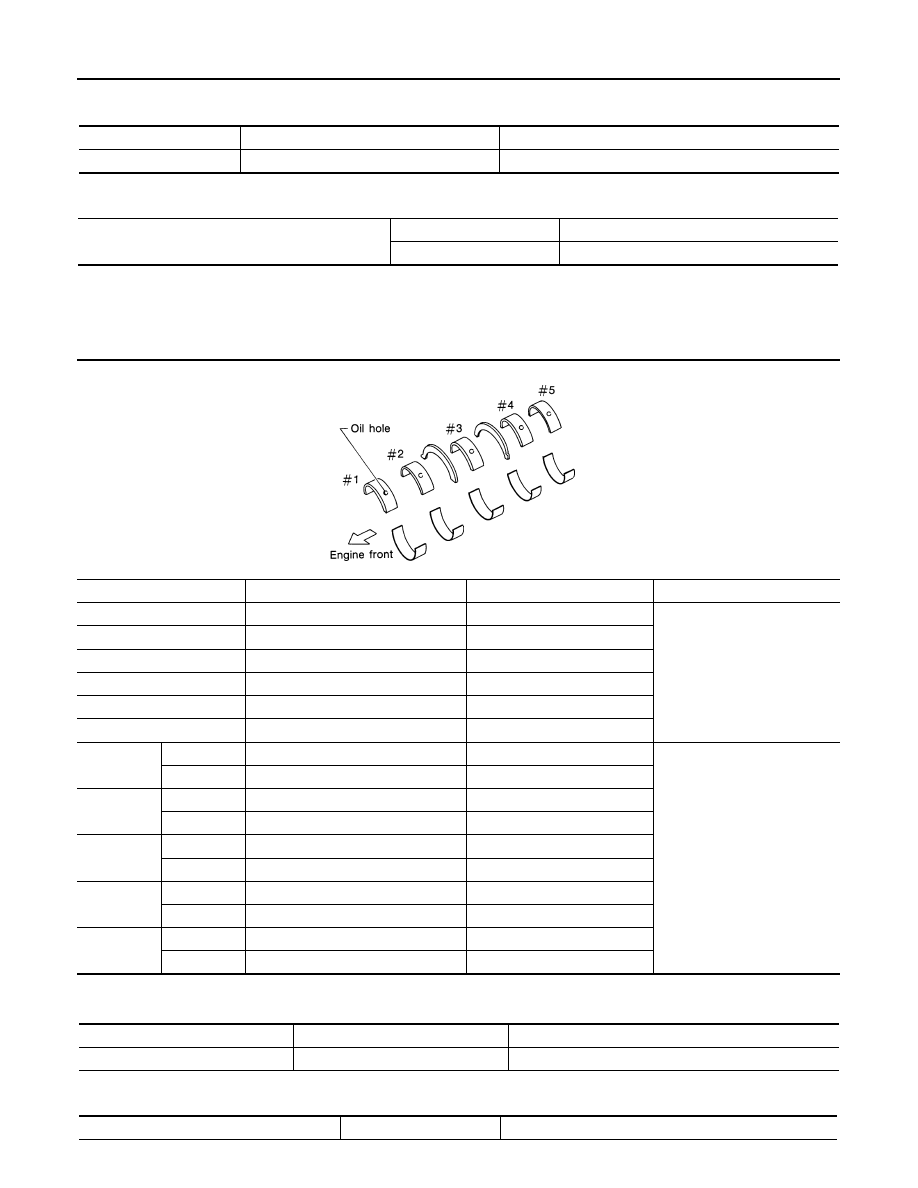

MAIN BEARING GRADE TABLE

Unit: mm (in)

UNDERSIZE TABLE

Unit: mm (in)

MAIN BEARING OIL CLEARANCE

Unit: mm (in)

Item

Thickness

Crankshaft pin journal diameter

US 0.25 (0.0098)

1.627 - 1.635 (0.0641 - 0.0644)

Grind so that bearing clearance is the specified value.

Connecting rod bearing oil clearance

Standard

0.029 - 0.039 (0.0011 - 0.0015)

Limit

0.10 (0.0039)

Grade number

Thickness

Identification color

Remarks

0

1.996 - 1.999 (0.0786 - 0.0787)

Black

Grade and color are the same

for upper and lower bearings.

1

1.999 - 2.002 (0.0787 - 0.0788)

Brown

2

2.002 - 2.005 (0.0788 - 0.0789)

Green

3

2.005 - 2.008 (0.0789 - 0.0791)

Yellow

4

2.008 - 2.011 (0.0791 - 0.0792)

Blue

5

2.011 - 2.014 (0.0792 - 0.0793)

Pink

01

UPR

1.996 - 1.999 (0.0786 - 0.0787)

Black

Grade and color are different

for upper and lower bearings.

LWR

1.999 - 2.002 (0.0787 - 0.0788)

Brown

12

UPR

1.999 - 2.002 (0.0787 - 0.0788)

Brown

LWR

2.002 - 2.005 (0.0788 - 0.0789)

Green

23

UPR

2.002 - 2.005 (0.0788 - 0.0789)

Green

LWR

2.005 - 2.008 (0.0789 - 0.0791)

Yellow

34

UPR

2.005 - 2.008 (0.0789 - 0.0791)

Yellow

LWR

2.008 - 2.011 (0.0791 - 0.0792)

Blue

45

UPR

2.008 - 2.011 (0.0791 - 0.0792)

Blue

LWR

2.011 - 2.014 (0.0792 - 0.0793)

Pink

SEM685D

Items

Thickness

Main journal diameter

0.25 (0.0098)

2.126 - 2.134 (0.0837 - 0.0840)

Grind so that bearing clearance is the specified value.

Main bearing oil clearance

Standard

0.024 - 0.034 (0.0009 - 0.0013)

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

EM-125

< SYMPTOM DIAGNOSIS >

[MR20DE]

C

D

E

F

G

H

I

J

K

L

M

A

EM

N

P

O

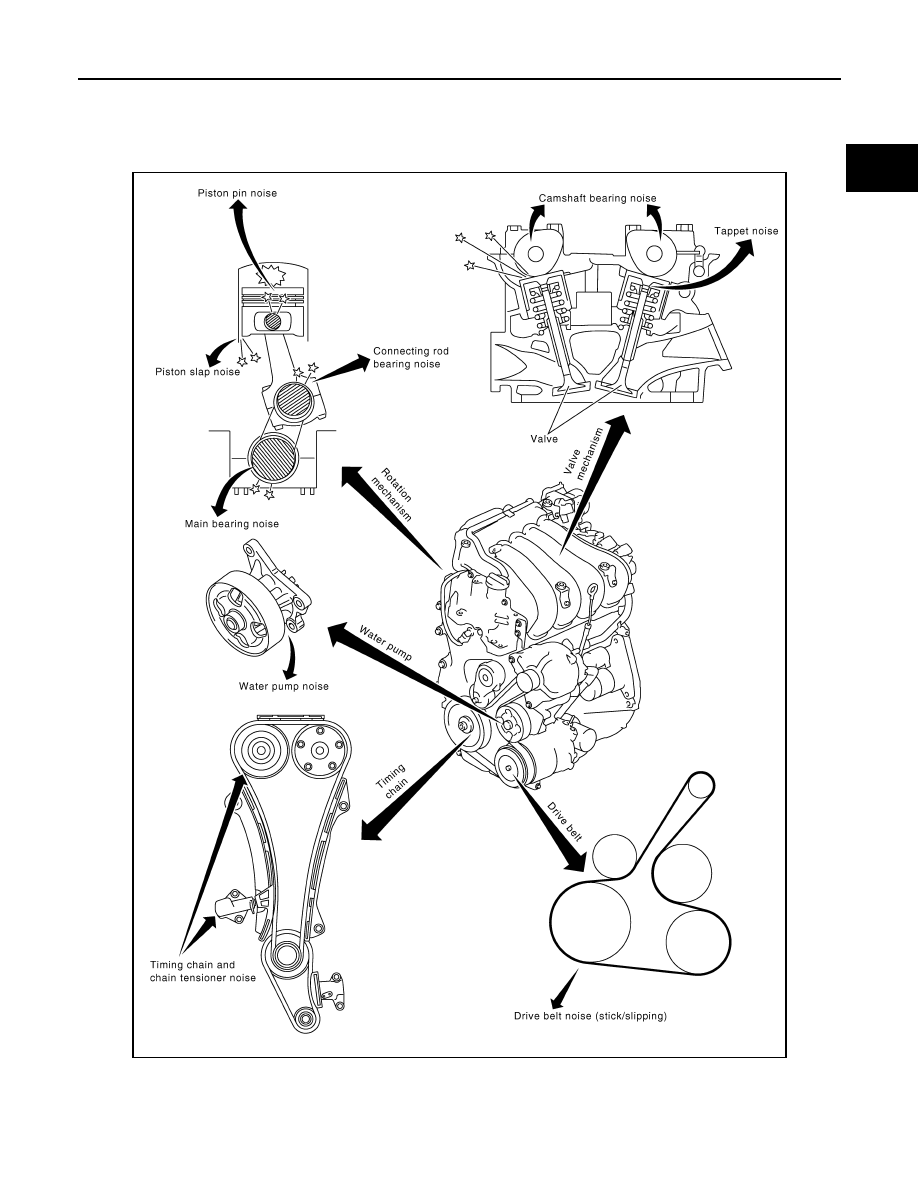

SYMPTOM DIAGNOSIS

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

NVH troubleshooting Chart

INFOID:0000000000893919

1.

Locate the area where noise occurs.

2.

Confirm the type of noise.

3.

Specify the operating condition of engine.

4.

Check specified noise source.

PBIC3932E

EM-126

< SYMPTOM DIAGNOSIS >

[MR20DE]

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

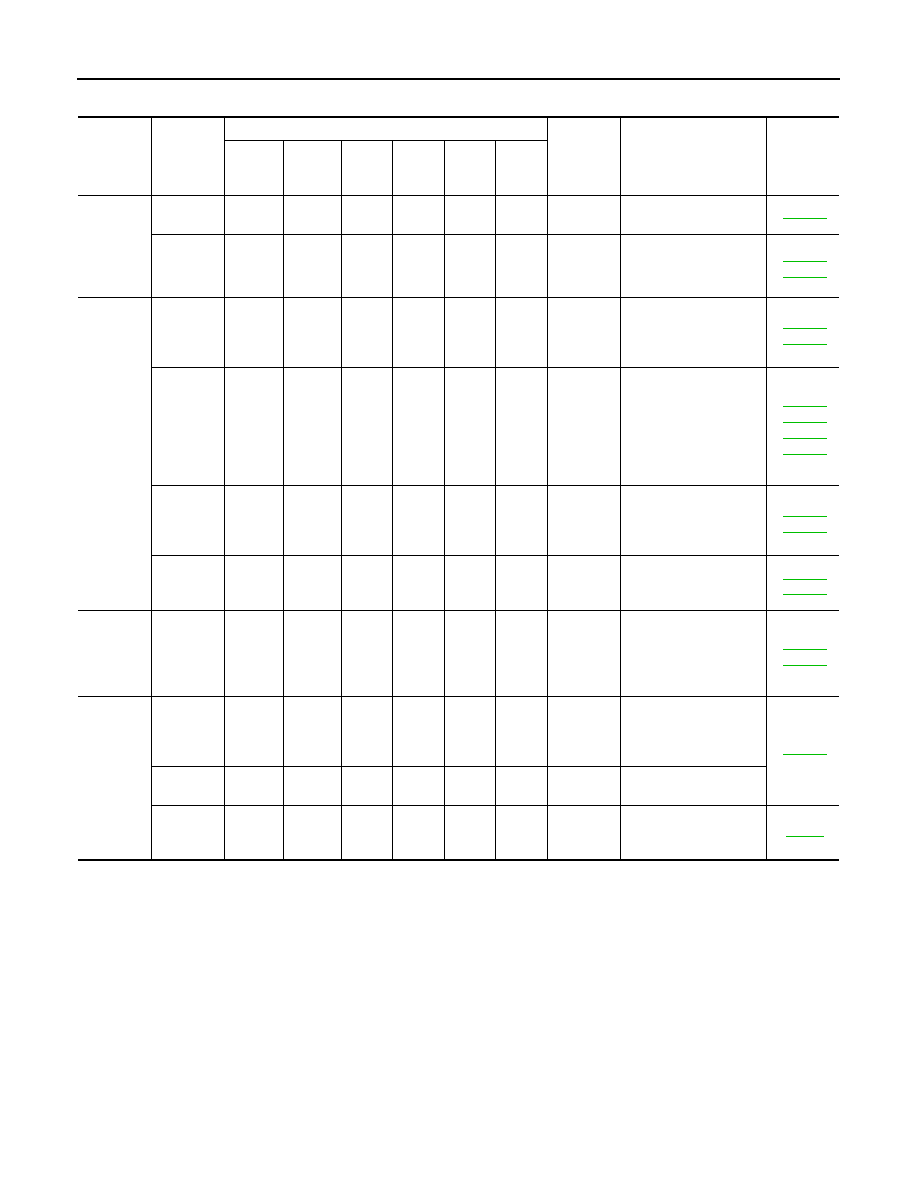

If necessary, repair or replace these parts.

A: Closely related

B: Related

C: Sometimes related

—: Not related

Location

of noise

Type of

noise

Operating condition of engine

Source of

noise

Check item

Refer-

ence page

Before

warm-

up

After

warm-

up

When

start-

ing

When

idling

When

racing

While

driving

Top of en-

gine

Rocker

cover

Cylinder

head

Ticking or

clicking

C

A

—

A

B

—

Tappet

noise

Valve clearance

Rattle

C

A

—

A

B

C

Camshaft

bearing

noise

Camshaft journal oil

clearance

Camshaft runout

Crank-

shaft pul-

ley

Cylinder

block

(Side of

engine)

Oil pan

Slap or

knock

—

A

—

B

B

—

Piston pin

noise

Piston to piston pin oil

clearance

Connecting rod bushing

oil clearance

Slap or

rap

A

—

—

B

B

A

Piston

slap noise

Piston to cylinder bore

clearance

Piston ring side clear-

ance

Piston ring end gap

Connecting rod bend

and torsion

Knock

A

B

C

B

B

B

Connect-

ing rod

bearing

noise

Connecting rod bushing

oil clearance

Connecting rod bearing

oil clearance

Knock

A

B

—

A

B

C

Main bear-

ing noise

Main bearing oil clear-

ance

Crankshaft runout

Front of

engine

Front cov-

er

Tapping or

ticking

A

A

—

B

B

B

Timing

chain and

chain ten-

sioner

noise

Timing chain cracks

and wear

Timing chain tensioner

operation

Front of

engine

Squeak-

ing or fizz-

ing

A

B

—

B

—

C

Drive belt

(Sticking

or slip-

ping)

Drive belt deflection

Creaking

A

B

A

B

A

B

Drive belt

(Slipping)

Idler pulley bearing op-

eration

Squall

Creak

A

B

—

B

A

B

Water

pump

noise

Water pump operation

PRECAUTIONS

EM-127

< PRECAUTION >

[MR20DE]

C

D

E

F

G

H

I

J

K

L

M

A

EM

N

P

O

PRECAUTION

PRECAUTIONS

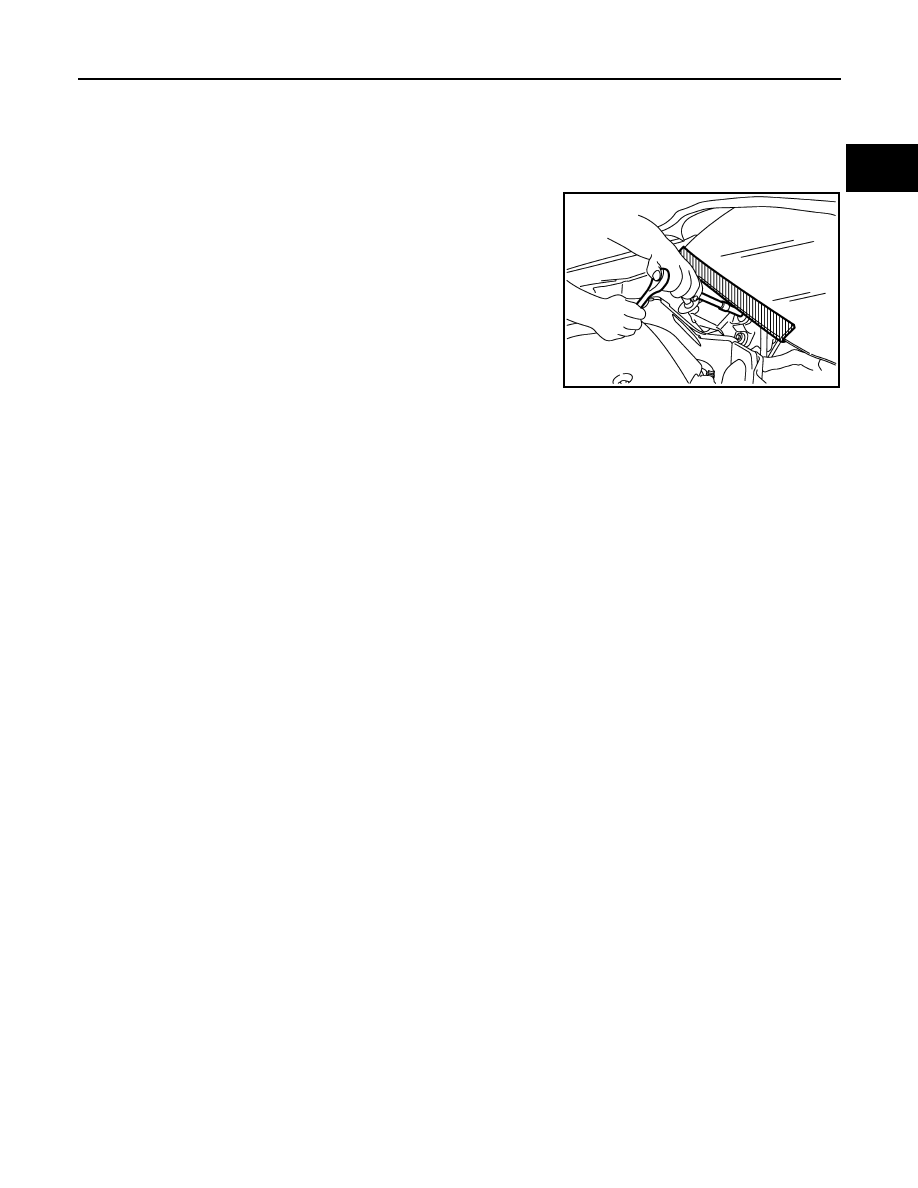

Precaution for Procedure without Cowl Top Cover

INFOID:0000000001117288

When performing the procedure after removing cowl top cover, cover

the lower end of windshield with urethane, etc.

Precaution Necessary for Steering Wheel Rotation After Battery Disconnect

INFOID:0000000001117287

NOTE:

• This Procedure is applied only to models with Intelligent Key system and NATS (NISSAN ANTI-THEFT SYS-

TEM).

• Remove and install all control units after disconnecting both battery cables with the ignition knob in the

″

LOCK

″

position.

• Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NATS, an electrically controlled steering lock mech-

anism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery power is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE

1.

Connect both battery cables.

NOTE:

Supply power using jumper cables if battery is discharged.

2.

Use the Intelligent Key or mechanical key to turn the ignition switch to the

″

ACC

″

position. At this time, the

steering lock will be released.

3.

Disconnect both battery cables. The steering lock will remain released and the steering wheel can be

rotated.

4.

Perform the necessary repair operation.

5.

When the repair work is completed, return the ignition switch to the

″

LOCK

″

position before connecting

the battery cables. (At this time, the steering lock mechanism will engage.)

6.

Perform a self-diagnosis check of all control units using CONSULT-III.

Draining Engine Coolant

INFOID:0000000000893910

Drain engine coolant and engine oil when the engine is cooled.

Disconnecting Fuel Piping

INFOID:0000000000893911

• Before starting work, make sure no fire or spark producing items are in the work area.

• Release fuel pressure before disconnecting and disassembly.

• After disconnecting pipes, plug openings to stop fuel leakage.

Removal and Disassembly

INFOID:0000000000893912

PIIB3706J

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст