Nissan Qashqai (2007-2010). Manual — part 32

EM-76

< ON-VEHICLE REPAIR >

[HR16DE]

CYLINDER HEAD

c.

Completely loosen.

CAUTION:

In this step, loosen bolts in reverse order of that indicated in the figure.

d.

Tighten all bolts.

e.

Turn all bolts 75 degrees clockwise (angle tightening).

CAUTION:

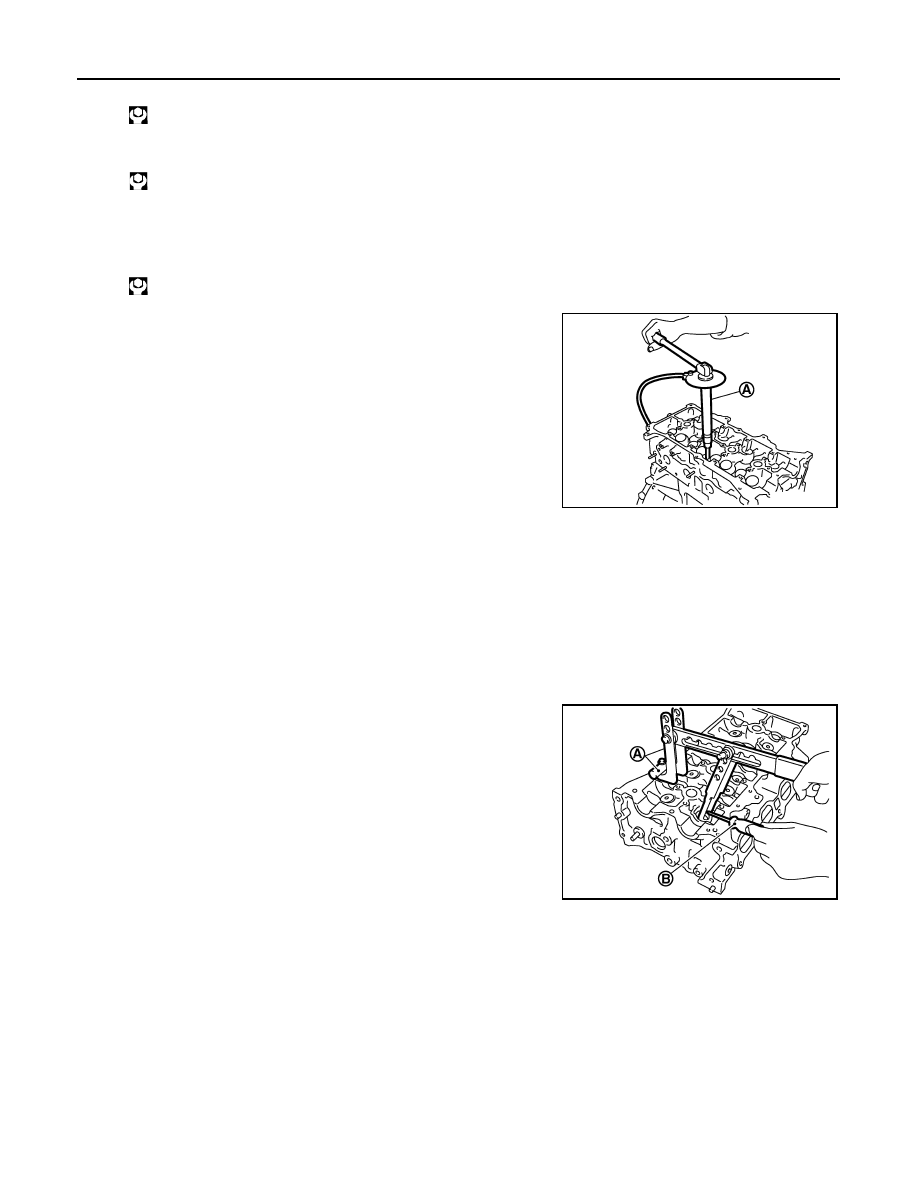

Check and confirm the tightening angle by using the angle

wrench [SST: KV10112100] (A) or protractor. Avoid judg-

ment by visual inspection without the tool.

f.

Turn all bolts 75 degrees clockwise again (angle tightening).

3.

Install in the reverse order of removal, for the rest of parts.

Disassembly and Assembly

INFOID:0000000000894030

DISASSEMBLY

1.

Remove spark plug with a spark plug wrench (commercial service tool).

2.

Remove valve lifter.

• Identify installation positions, and store them without mixing them up.

3.

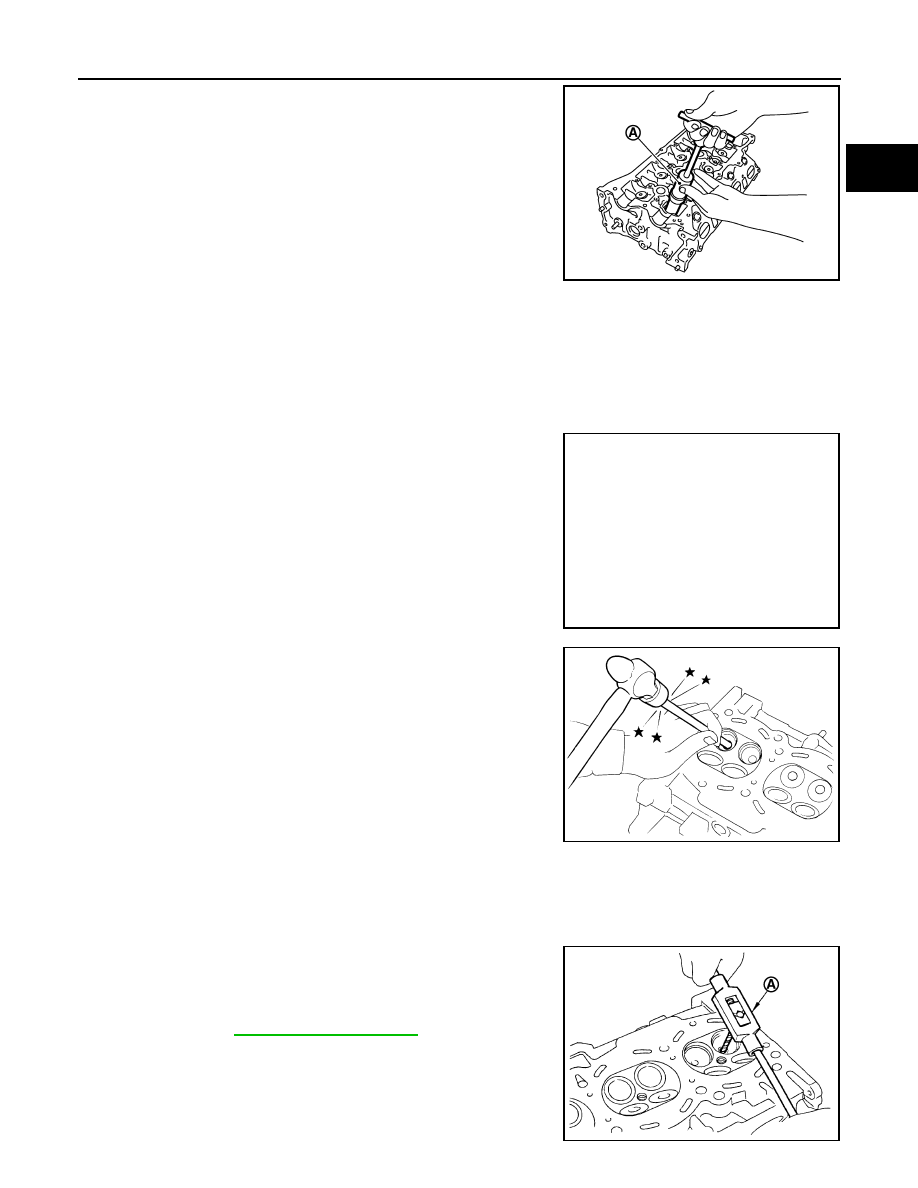

Remove valve collet.

• Compress valve spring with the valve spring compressor, the

attachment and the adapter [SST: KV10116200] (A). Remove

valve collet with a magnet hand (B).

CAUTION:

Be careful not to damage valve lifter holes.

4.

Remove valve spring retainer and valve spring.

5.

Push valve stem to combustion chamber side, and remove valve.

• Identify installation positions, and store them without mixing them up.

: 66.7 N·m (6.8 kg-m, 49 ft-lb)

: 0 N·m (0 kg-m, 0 ft-lb)

: 40.0 N·m (4.1 kg-m, 30 ft-lb)

PBIC3733E

PBIC3727E

CYLINDER HEAD

EM-77

< ON-VEHICLE REPAIR >

[HR16DE]

C

D

E

F

G

H

I

J

K

L

M

A

EM

N

P

O

6.

Remove valve oil seal with the valve oil seal puller [SST:

KV10107902] (A).

7.

Remove valve spring seat.

8.

Remove valve seat, if valve seat must be replaced.

• Bore out old seat until it collapses. Boring should not continue beyond the bottom face of the seat

recess in cylinder head. Set the machine depth stop to ensure this.

CAUTION:

Never bore excessively to prevent cylinder head from scratching.

9.

Remove valve guide, if valve guide must be replaced.

a.

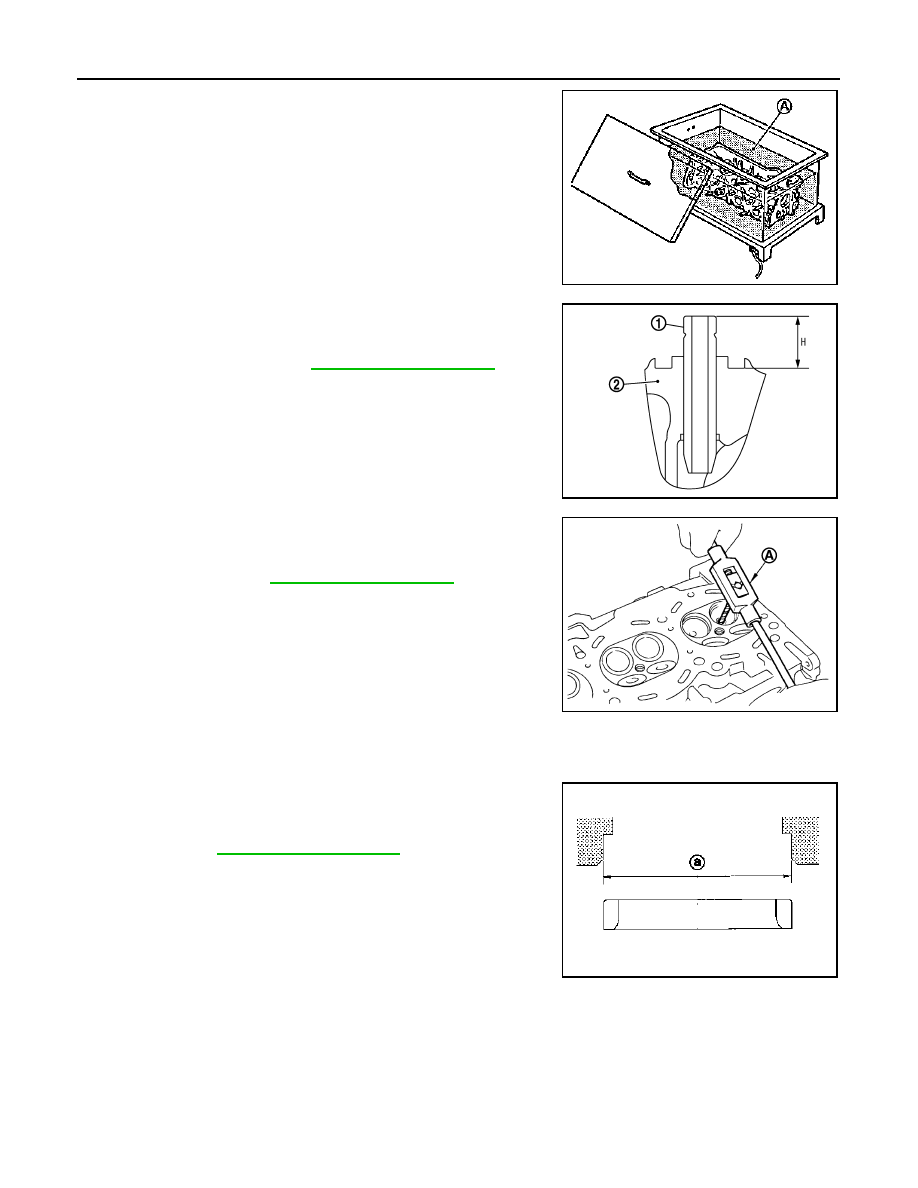

To remove valve guide, heat cylinder head to 110 to 130

°

C (230

to 266

°

F) by soaking in heated oil (A).

b.

Drive out valve guide with a press [under a 20 kN (2 ton, 2.2 US

ton, 2.0 lmp ton) pressure] or a hammer and the valve guide drift

(commercial service tool).

WARNING:

Cylinder head contains heat. Wear protective equipment to

avoid getting burned.

ASSEMBLY

1.

When valve guide is removed, install it.

CAUTION:

Replace with oversize [0.2 mm (0.008 in)] valve guide.

a.

Using the valve guide reamer (commercial service tool) (A),

ream cylinder head valve guide hole.

PBIC3728E

JPBIA0184ZZ

SEM931C

For service parts: Oversized [0.2 mm (0.008 in)]

PBIC3215J

EM-78

< ON-VEHICLE REPAIR >

[HR16DE]

CYLINDER HEAD

b.

Heat cylinder head to 110 to 130

°

C (230 to 266

°

F) by soaking in

heated oil (A).

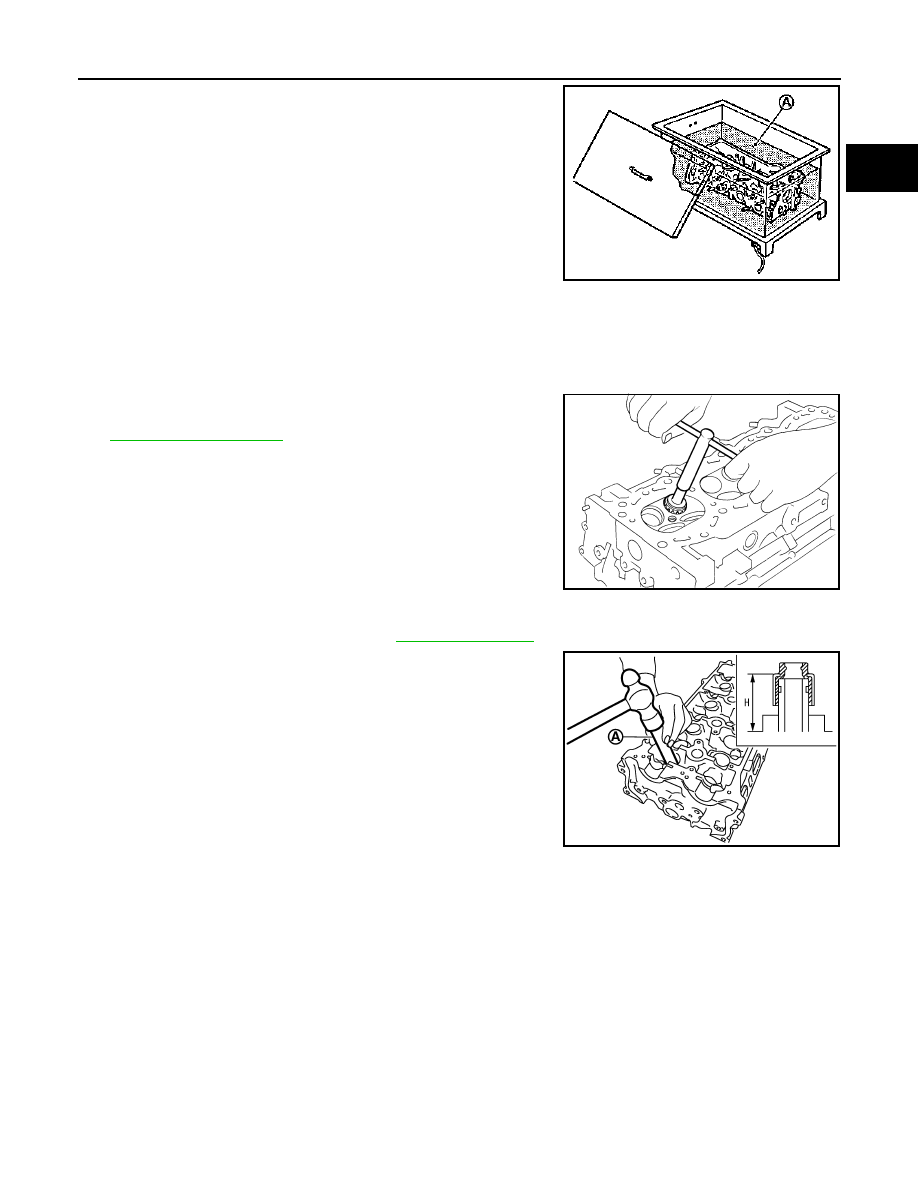

c.

Using the valve guide drift (commercial service tool), press valve

guide (1) from camshaft side to the dimensions as in the figure.

WARNING:

Cylinder head (2) contains heat. Wear protective equipment

to avoid getting burned.

d.

Using the valve guide reamer (commercial service tool) (A),

apply reamer finish to valve guide.

2.

When valve seat is removed, install it.

CAUTION:

Replace with oversize [0.5 mm (0.020 in)] valve seat.

a.

Ream cylinder head recess diameter (a) for service valve seat.

• Be sure to ream in circles concentric to valve guide center.

This will enable valve to fit correctly.

PBIC3214J

Projection “H”: Refer to

PBIC3217J

PBIC3215J

For service parts: Oversize [0.5 mm (0.020 in)]

Refer to

JPBIA0188ZZ

CYLINDER HEAD

EM-79

< ON-VEHICLE REPAIR >

[HR16DE]

C

D

E

F

G

H

I

J

K

L

M

A

EM

N

P

O

b.

Heat cylinder head to 110 to 130

°

C (230 to 266

°

F) by soaking in

heated oil (A).

c.

Provide valve seats cooled well with dry ice. Force fit valve seat into cylinder head.

WARNING:

Cylinder head contains heat. Wear protective equipment to avoid getting burned.

CAUTION:

Avoid directly touching cold valve seats.

d.

Using the valve seat cutter set (commercial service tool) or valve

seat grinder, finish seat to the specified dimensions. Refer to

.

CAUTION:

When using the valve seat cutter, firmly grip cutter handle

with both hands. Then, press on the contacting surface all

around the circumference to cut in a single drive. Improper

pressure on with cutter or cutting many different times may

result in stage valve seat.

e.

Using compound, grind to adjust valve fitting.

f.

Check again for normal contact. Refer to

3.

Install valve oil seal.

• Install with the valve oil seal drift [SST: KV10115600] (A) to

match dimension in the figure.

4.

Install valve spring seat.

5.

Install valve.

• Install larger diameter to intake side.

6.

Install valve spring.

NOTE:

It can be installed in either direction.

7.

Install valve spring retainer.

8.

Install valve collet.

PBIC3214J

SEM934C

Height “H”

: 13.2 - 13.8 mm (0.520 - 0.543 in)

PBIC3211J

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст