Nissan Qashqai (2007-2010). Manual — part 69

EM-224

< DISASSEMBLY AND ASSEMBLY >

[MR20DE]

CYLINDER BLOCK

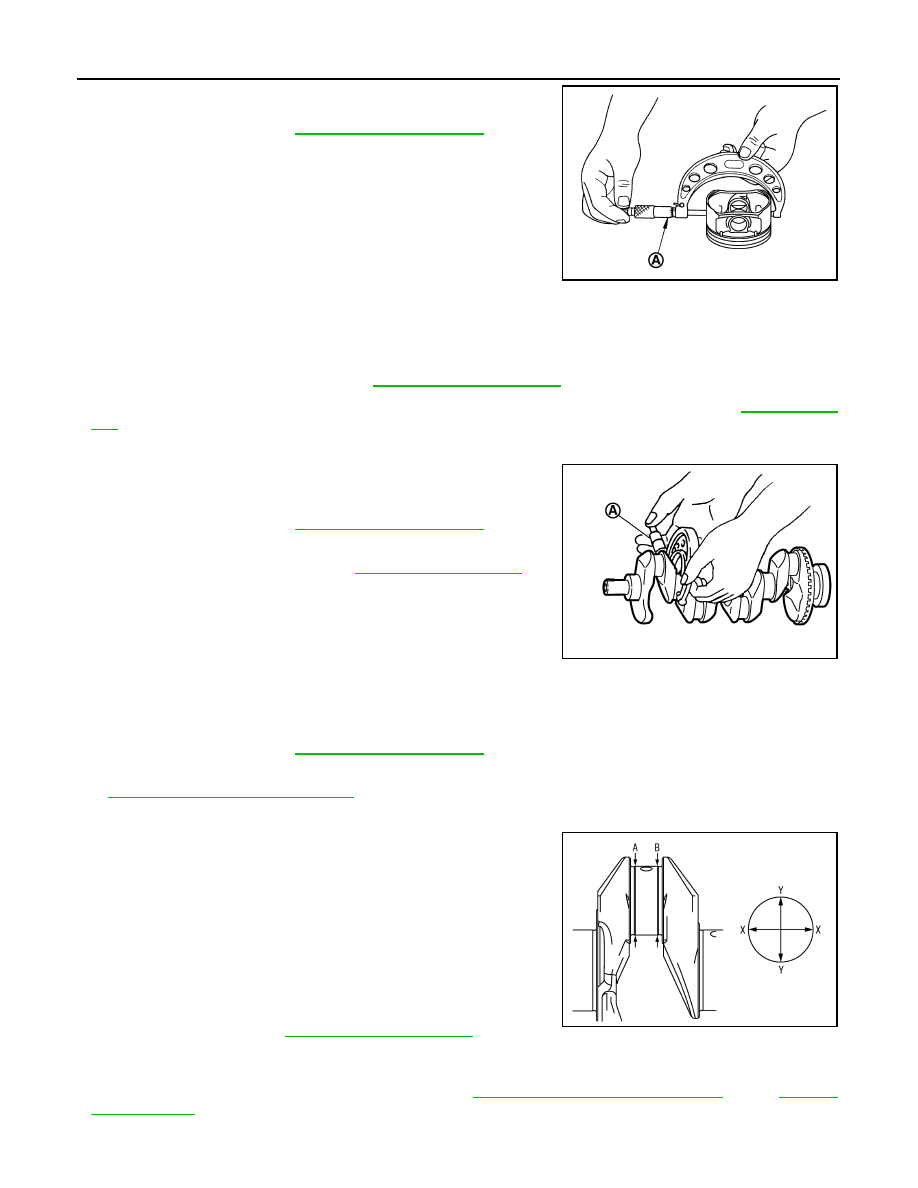

Measure the outer diameter of piston skirt with a micrometer (A).

Piston to Cylinder Bore Clearance

Calculate by piston skirt diameter and cylinder bore inner diameter (direction “X”, position “B”).

(Clearance) = (Cylinder bore inner diameter) – (Piston skirt diameter)

• If it exceeds the limit, replace piston and piston pin assembly and/or cylinder block. Refer to

.

CRANKSHAFT MAIN JOURNAL DIAMETER

• Measure the outer diameter of crankshaft main journals with a

micrometer (A).

• If out of the standard, measure the main bearing oil clearance.

Then use undersize bearing. Refer to

CRANKSHAFT PIN JOURNAL DIAMETER

• Measure the outer diameter of crankshaft pin journal with a micrometer.

• If out of the standard, measure the connecting rod bearing oil clearance. Then use undersize bearing. Refer

EM-244, "Connecting Rod Bearing"

.

OUT-OF-ROUND AND TAPER OF CRANKSHAFT

• Measure the dimensions at four different points as shown in the

figure on each main journal and pin journal with a micrometer.

• Out-of-round is indicated by the difference in dimensions between

“X” and “Y” at “A” and “B”.

• Taper is indicated by the difference in dimension between “A” and

“B” at “X” and “Y”.

• If the measured value exceeds the limit, correct or replace crankshaft.

• If corrected, measure the bearing oil clearance of the corrected main journal and/or pin journal. Then select

main bearing and/or connecting rod bearing. Refer to

EM-244, "Connecting Rod Bearing"

CRANKSHAFT RUNOUT

Standard :

PBIC3272J

Standard and Limit

: Refer to

.

Standard :

PBIC3457J

Standard :

Limit:

Out-of-round (Difference between“X”and“Y”)

Taper (Difference between“A”and“B”)

: Refer to

.

PBIC3459J

CYLINDER BLOCK

EM-225

< DISASSEMBLY AND ASSEMBLY >

[MR20DE]

C

D

E

F

G

H

I

J

K

L

M

A

EM

N

P

O

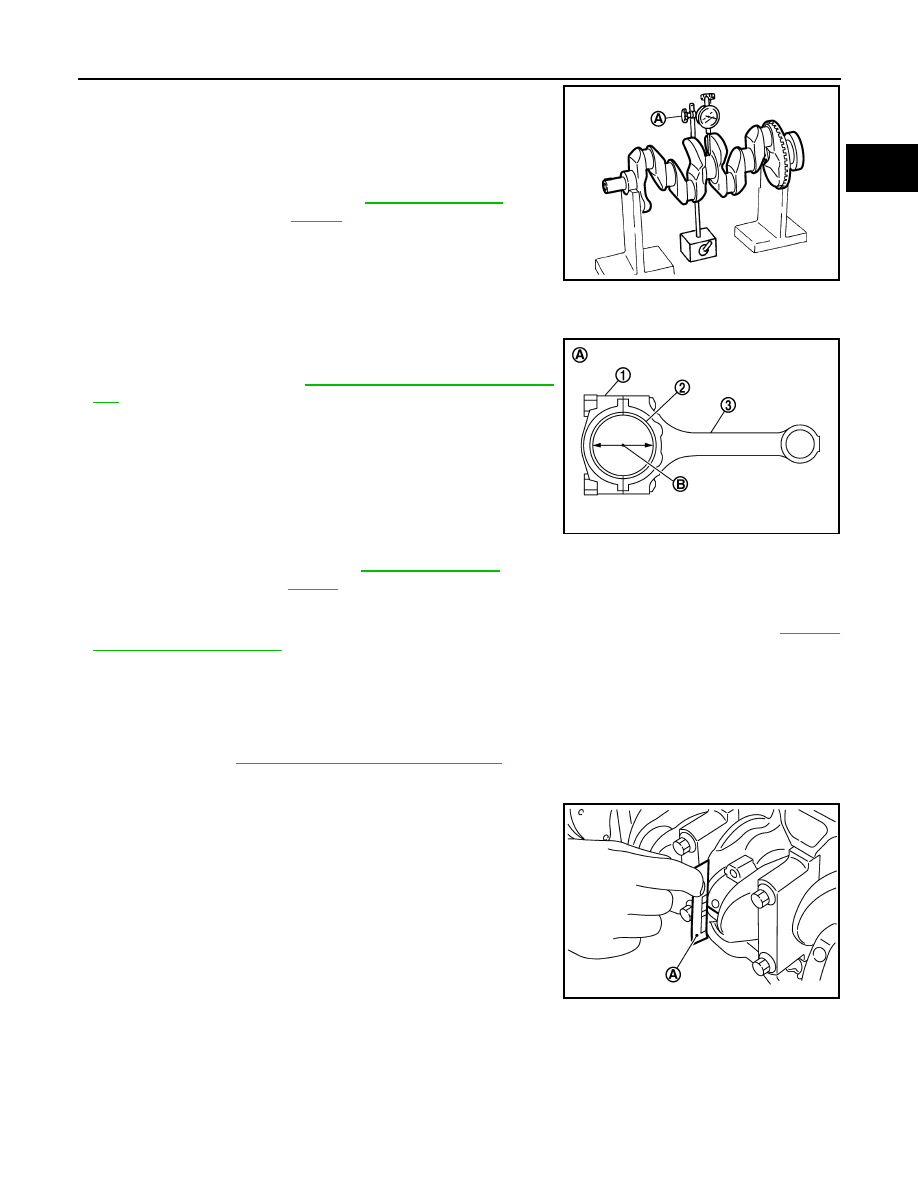

• Place a V-block on a precise flat table to support the journals on

the both end of the crankshaft.

• Place a dial indicator (A) straight up on the No. 3 journal.

• While rotating crankshaft, read the movement of the pointer on the

dial indicator. (Total indicator reading)

• If it exceeds the limit, replace crankshaft.

CONNECTING ROD BEARING OIL CLEARANCE

Method by Calculation

• Install connecting rod bearings (2) to connecting rod (3) and con-

necting rod bearing cap (1), and tighten connecting rod cap bolts to

the specified torque. Refer to

EM-211, "Disassembly and Assem-

• Measure the inner diameter of connecting rod bearing with an

inside micrometer.

(Bearing oil clearance) = (Connecting rod bearing inner diameter)

– (Crankshaft pin journal diameter)

• If clearance exceeds the limit, select proper connecting rod bearing according to connecting rod big end

diameter and crankshaft pin journal diameter to obtain specified bearing oil clearance. Refer to

.

Method of Using Plastigage

• Remove engine oil and dust on crankshaft pin and the surfaces of each bearing completely.

• Cut a plastigage slightly shorter than the bearing width, and place it in crankshaft axial direction, avoiding oil

holes.

• Install connecting rod bearings to connecting rod and cap, and tighten connecting rod cap bolts to the speci-

EM-211, "Disassembly and Assembly"

CAUTION:

Never rotate crankshaft.

• Remove connecting rod cap and bearing, and using the scale (A)

on the plastigage bag, measure the plastigage width.

NOTE:

The procedure when the measured value exceeds the limit is

same as that described in the “Method by Calculation”.

MAIN BEARING OIL CLEARANCE

Method by Calculation

Standard and Limit

: Refer to

PBIC3458J

A

: Example

B

: Inner diameter measuring direction

Standard and Limit

: Refer to

.

PBIC3275J

PBIC3276J

EM-226

< DISASSEMBLY AND ASSEMBLY >

[MR20DE]

CYLINDER BLOCK

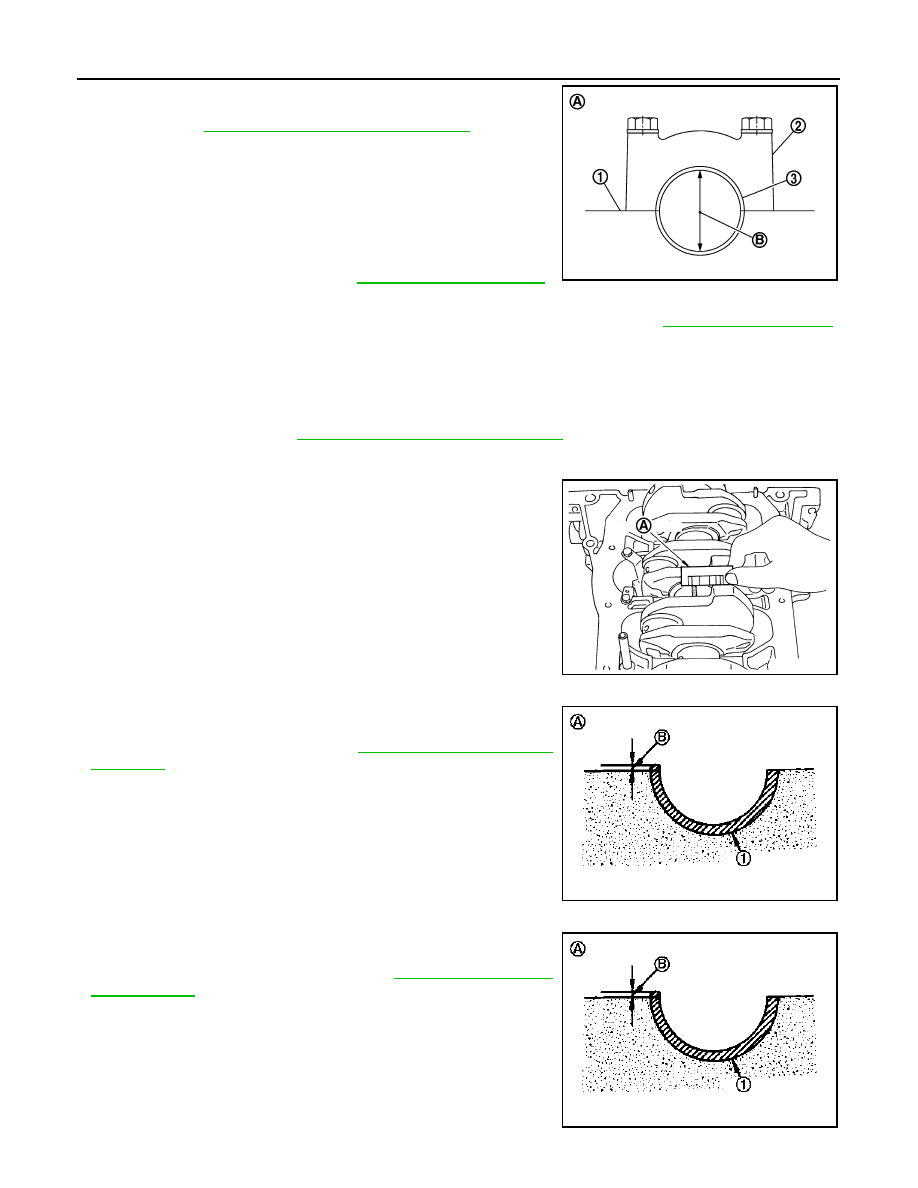

• Install main bearings (3) to cylinder block (1) and main bearing cap

(2), and tighten main bearing cap mounting bolts to the specified

torque. Refer to

EM-211, "Disassembly and Assembly"

.

• Measure the inner diameter of main bearing with a bore gauge.

(Bearing oil clearance) = (Main bearing inner diameter) – (Crank-

shaft main journal diameter)

• If clearance exceeds the limit, select proper main bearing according to main bearing inner diameter and

crankshaft main journal diameter to obtain specified bearing oil clearance. Refer to

.

Method of Using Plastigage

• Remove engine oil and dust on crankshaft main journal and the surfaces of each bearing completely.

• Cut a plastigage slightly shorter than the bearing width, and place it in crankshaft axial direction, avoiding oil

holes.

• Install main bearings to cylinder block and main bearing cap, and tighten main bearing cap mounting bolts to

the specified torque. Refer to

EM-211, "Disassembly and Assembly"

CAUTION:

Never rotate crankshaft.

• Remove main bearing cap and bearings, and using the scale (A)

on the plastigage bag, measure the plastigage width.

NOTE:

The procedure when the measured value exceeds the limit is

same as that described in the “Method by Calculation”.

MAIN BEARING CRUSH HEIGHT

• When main bearing cap is removed after being tightened to the

specified torque with main bearings (1) installed, the tip end of

bearing must protrude (B). Refer to

• If the standard is not met, replace main bearings.

CONNECTING ROD BEARING CRUSH HEIGHT

• When connecting rod cap is removed after being tightened to the

specified torque with connecting rod bearings (1) installed, the tip

end of bearing must protrude (B). Refer to

.

• If the standard is not met, replace connecting rod bearings.

A

: Example

B

: Inner diameter measuring direction

Standard and Limit

: Refer to

PBIC3277J

PBIC3278J

A

: Example

Standard

: There must be crush height.

PBIC3279J

A

: Example

Standard

: There must be crush height.

PBIC3279J

CYLINDER BLOCK

EM-227

< DISASSEMBLY AND ASSEMBLY >

[MR20DE]

C

D

E

F

G

H

I

J

K

L

M

A

EM

N

P

O

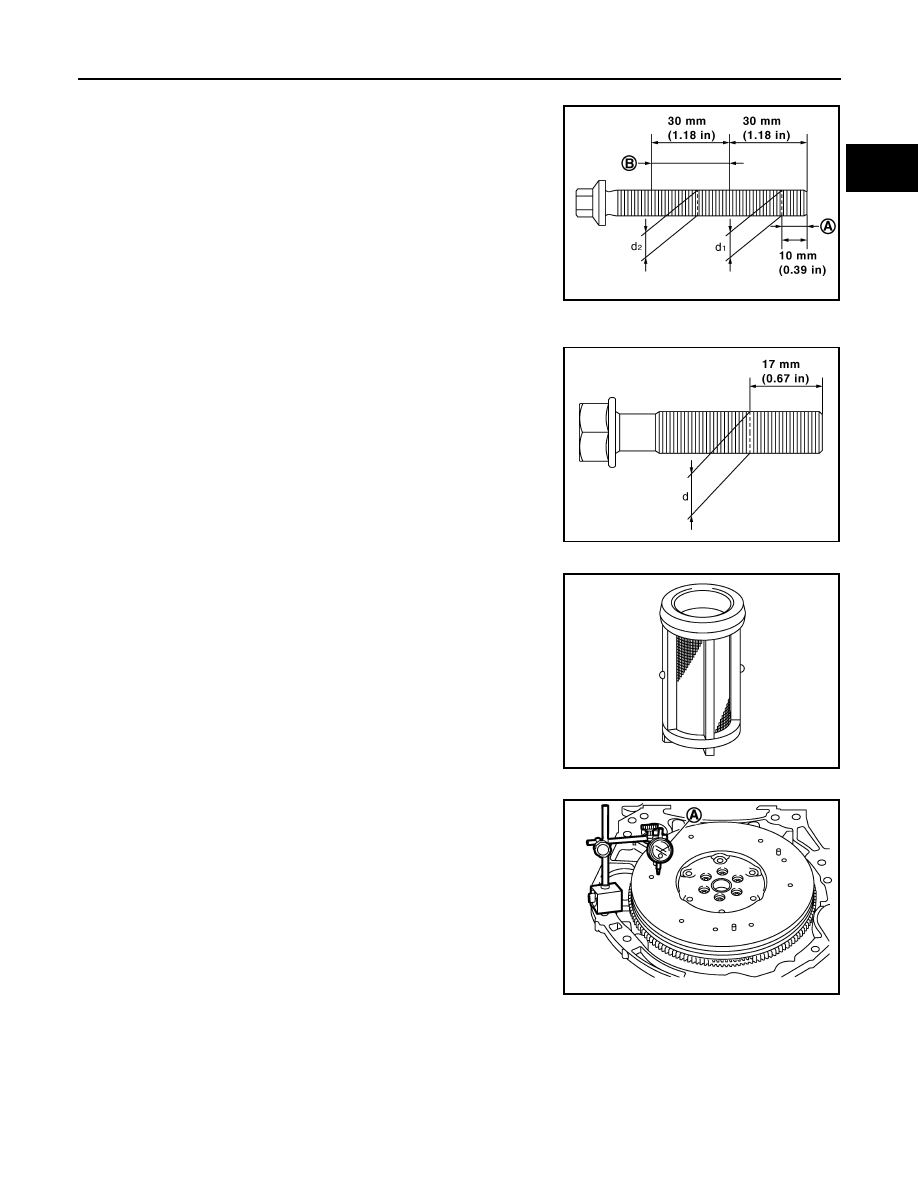

MAIN BEARING CAP BOLT OUTER DIAMETER

• Measure the outer diameters (“d

1

”, “d

2”

) at two positions as shown

in the figure.

• If reduction appears in places other than “B” range, regard it as

“d

2

”.

• If it exceeds the limit (a large difference in dimensions), replace

main bearing cap mounting bolt with a new one.

CONNECTING ROD CAP BOLT OUTER DIAMETER

• Measure the outer diameter “d” at position as shown in the figure.

• If reduction appears in a position other than “d”, regard it as “d”.

• When “d” exceeds the limit (when it becomes thinner), replace

connecting rod cap bolt with a new one.

CLOGGED OR DAMAGED OIL FILTER (FOR INTAKE VALVE TIMING CONTROL)

• Make sure that there is no foreign material on the oil filter and

check it for clogging.

- Clean it if necessary.

• Check the oil filter for damage.

- Replace it if necessary.

FLYWHEEL DEFLECTION (M/T MODELS)

• Measure the deflection of flywheel contact surface to torque with a

dial indicator (A).

• Measure the deflection at 210 mm (8.27 in) diameter.

• If measured value is out of the standard, replace flywheel.

• If a trace of burn or discoloration is found on the surface, repair it

with sandpaper.

CAUTION:

When measuring, keep magnetic fields (such as dial indicator

stand) away from signal plate of the rear end of crankshaft.

MOVEMENT AMOUNT OF FLYWHEEL (M/T MODELS)

CAUTION:

Never disassemble double mass flywheel.

Movement Amount of Thrust (Fore-and-Aft) Direction

• Measure the movement amount of thrust (fore-and-aft) direction when 100 N (10.2 kg, 22 lb) force is added

at the portion of 125 mm (4.92 in) radius from the center of flywheel.

A

: “d1” measuring position

B

: “d2” measuring position

Limit (“d

1

”–“d

2

”): 0.15 mm (0.0059 in)

PBIC4015E

Limit: 7.75 mm (0.3051 in)

PBIC4016E

PBIC3273J

Limit : 0.45 mm (0.0177 in) or less.

PBIC4006E

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст