Subaru Impreza 3 / Impreza WRX / Impreza WRX STI. Service manual — part 246

EN(H4DOTC)(diag)-208

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

ENGINE (DIAGNOSTICS)

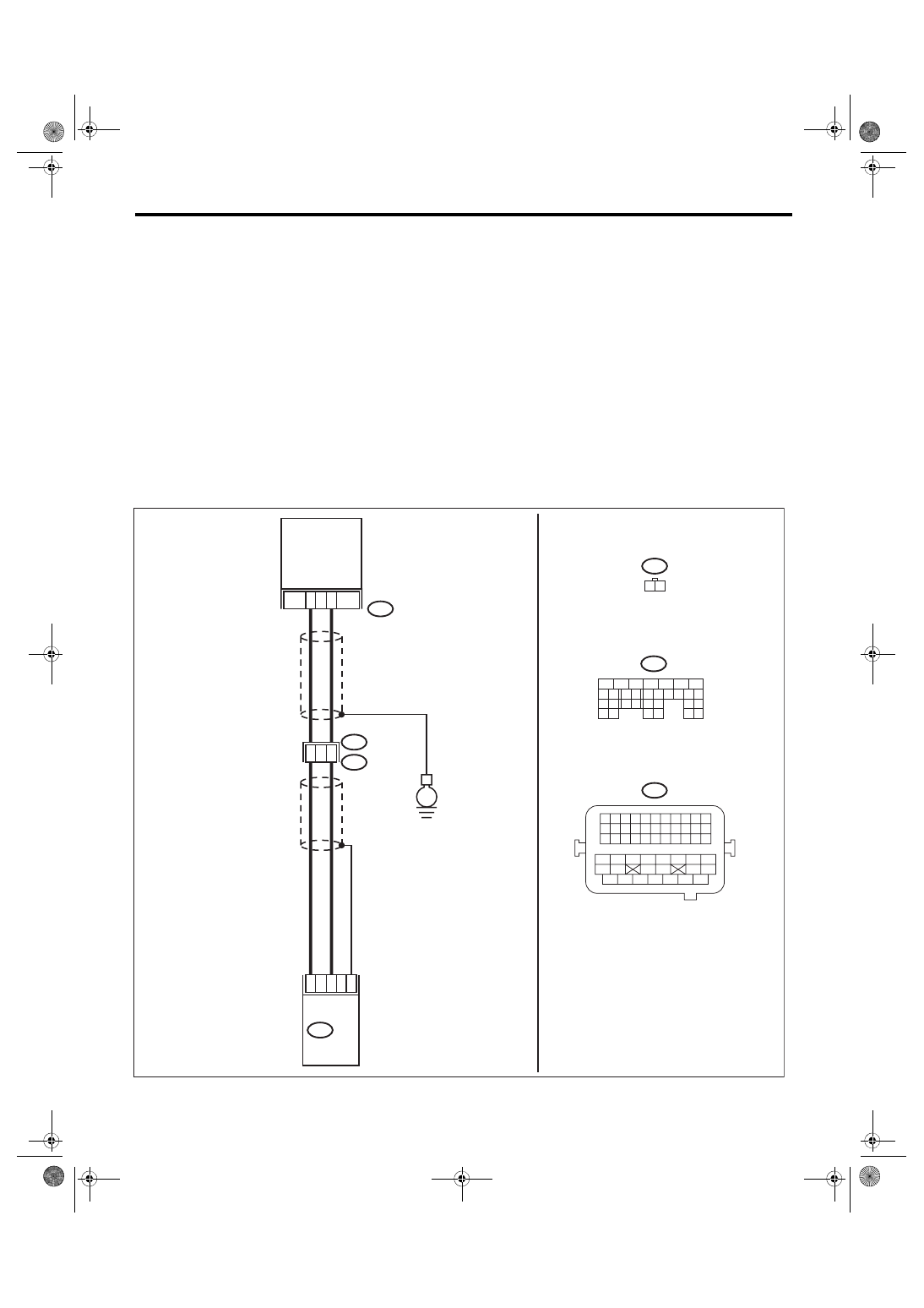

BL:DTC P0335 CRANKSHAFT POSITION SENSOR “A” CIRCUIT

DTC DETECTING CONDITION:

• Immediately at fault recognition

• GENERAL DESCRIPTION <Ref. to GD(H4DOTC)-128, DTC P0335 CRANKSHAFT POSITION SENSOR

“A” CIRCUIT, Diagnostic Trouble Code (DTC) Detecting Criteria.>

TROUBLE SYMPTOM:

• Engine stalls.

• Failure of engine to start

CAUTION:

After servicing or replacing faulty parts, perform Clear Memory Mode <Ref. to EN(H4DOTC)(diag)-63,

OPERATION, Clear Memory Mode.>, and Inspection Mode <Ref. to EN(H4DOTC)(diag)-49, PROCE-

WIRING DIAGRAM:

• Engine electrical system, without SI-DRIVE <Ref. to WI-32, WITHOUT SI-DRIVE, WIRING DIAGRAM,

• Engine electrical system, with SI-DRIVE <Ref. to WI-48, WITH SI-DRIVE, WIRING DIAGRAM, Engine

ECM

EN-08731

1

2

14

3

25

31

E10

B21

B137

31

30

29

28

27

21

20

19

18

17

16

26

25

24

15

14

13

12

11

23

22

10

3

4

9

1

2

8

7

6

5

33

32

31

30

29

28

27

26

47

46

45

44

43

42

54

53

52

51

50

49

48

41

40

39

38

37

36

35

34

25

24

23

22

21

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

17

B137

2

1

E10

E2

B21

E

CRANKSHAFT

POSITION

SENSOR

EN(H4DOTC)(diag)-209

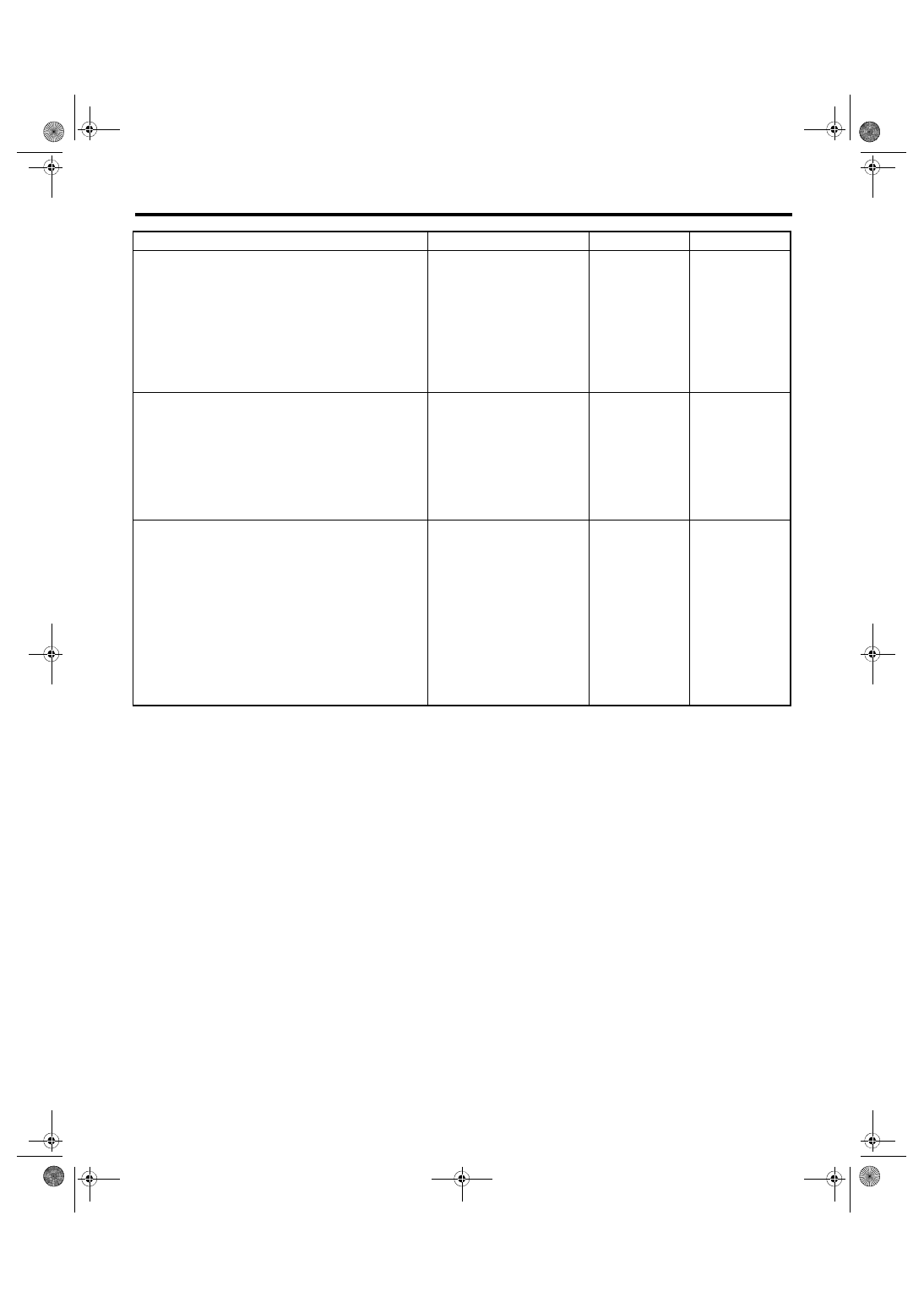

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

ENGINE (DIAGNOSTICS)

Step

Check

Yes

No

1

CHECK CONDITION OF CRANKSHAFT PO-

SITION SENSOR.

Is the crankshaft position sen-

sor installation bolt tightened

securely?

2

CHECK CRANKSHAFT POSITION SENSOR.

1) Turn the ignition switch to OFF.

2) Remove the crankshaft position sensor.

3) Measure the resistance between terminals

of crankshaft position sensor.

Terminals

No. 1 — No. 2:

Is the resistance between 1 and

4 kΩ?

3

CHECK HARNESS BETWEEN ECM AND

CRANKSHAFT POSITION SENSOR CON-

NECTOR.

1) Disconnect the connector from ECM.

2) Measure the resistance of harness between

ECM connector and crankshaft position sensor

connector.

Connector & terminal

(B137) No. 17 — (E10) No. 1:

(B137) No. 25 — (E10) No. 2:

Is the resistance less than 1 Ω? Repair the poor

contact of ECM

and crankshaft

position sensor

connector.

Repair the harness

and connector.

NOTE:

In this case, repair

the following item:

• Open circuit in

harness between

ECM

connector

and crankshaft po-

sition sensor con-

nector

• Poor contact of

coupling connector

EN(H4DOTC)(diag)-210

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

ENGINE (DIAGNOSTICS)

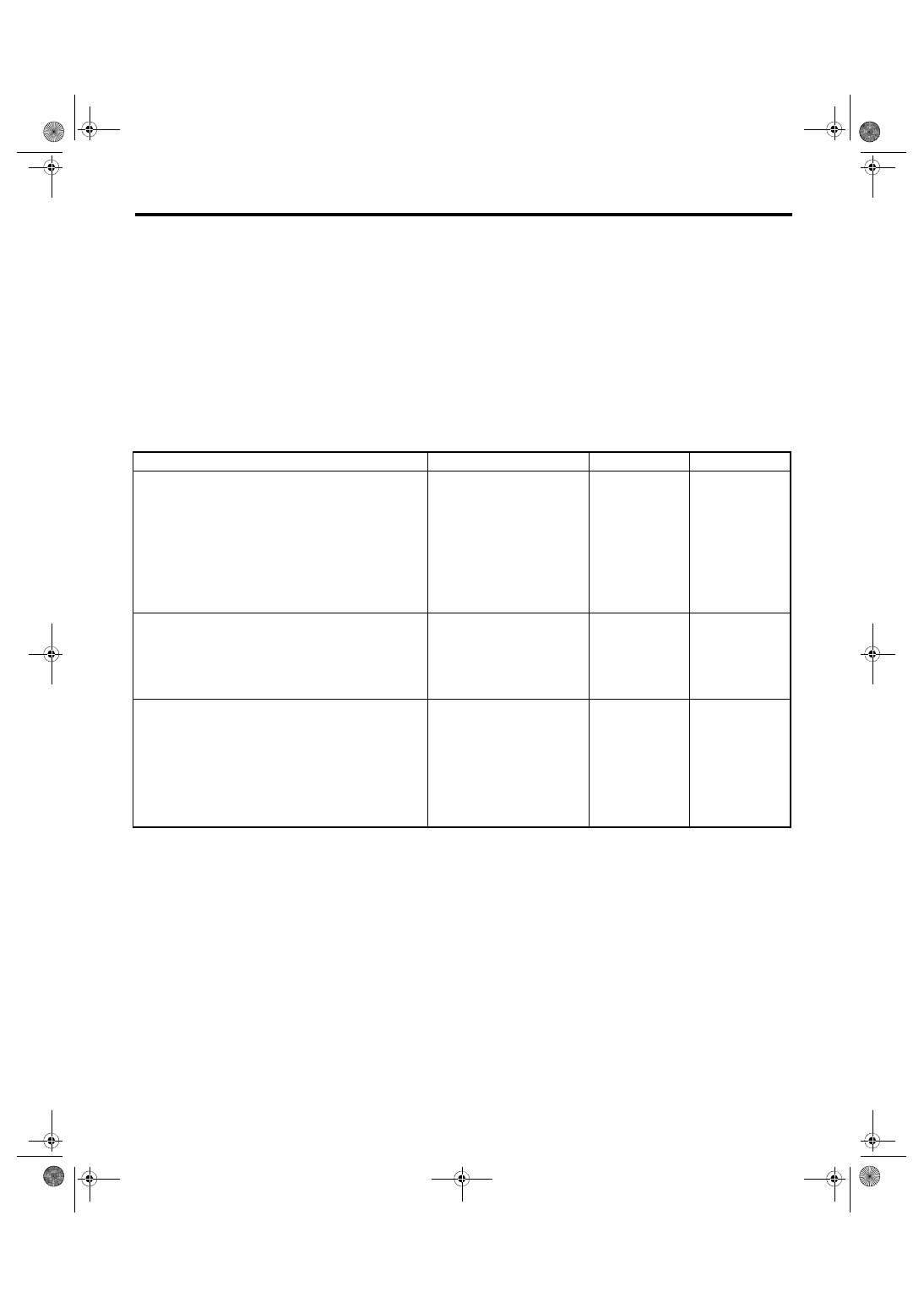

BM:DTC P0336 CRANKSHAFT POSITION SENSOR “A” CIRCUIT RANGE/PER-

FORMANCE

DTC DETECTING CONDITION:

• Detected when two consecutive driving cycles with fault occur.

• GENERAL DESCRIPTION <Ref. to GD(H4DOTC)-130, DTC P0336 CRANKSHAFT POSITION SENSOR

“A” CIRCUIT RANGE/PERFORMANCE, Diagnostic Trouble Code (DTC) Detecting Criteria.>

TROUBLE SYMPTOM:

• Engine stalls.

• Failure of engine to start

CAUTION:

After servicing or replacing faulty parts, perform Clear Memory Mode <Ref. to EN(H4DOTC)(diag)-63,

OPERATION, Clear Memory Mode.>, and Inspection Mode <Ref. to EN(H4DOTC)(diag)-49, PROCE-

Step

Check

Yes

No

1

CHECK CONDITION OF CRANKSHAFT PO-

SITION SENSOR.

Turn the ignition switch to OFF.

Is the crankshaft position sen-

sor installation bolt tightened

securely?

2

CHECK CRANK SPROCKET.

Remove the timing belt cover.

Are crank sprocket teeth

cracked or damaged?

3

CHECK INSTALLATION CONDITION OF

TIMING BELT.

Turn the crankshaft, and align alignment mark

on crank sprocket with alignment mark on cylin-

der block.

ST 499987500

CRANKSHAFT

SOCKET

Is the timing belt dislocated

from its proper position?

EN(H4DOTC)(diag)-211

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

ENGINE (DIAGNOSTICS)

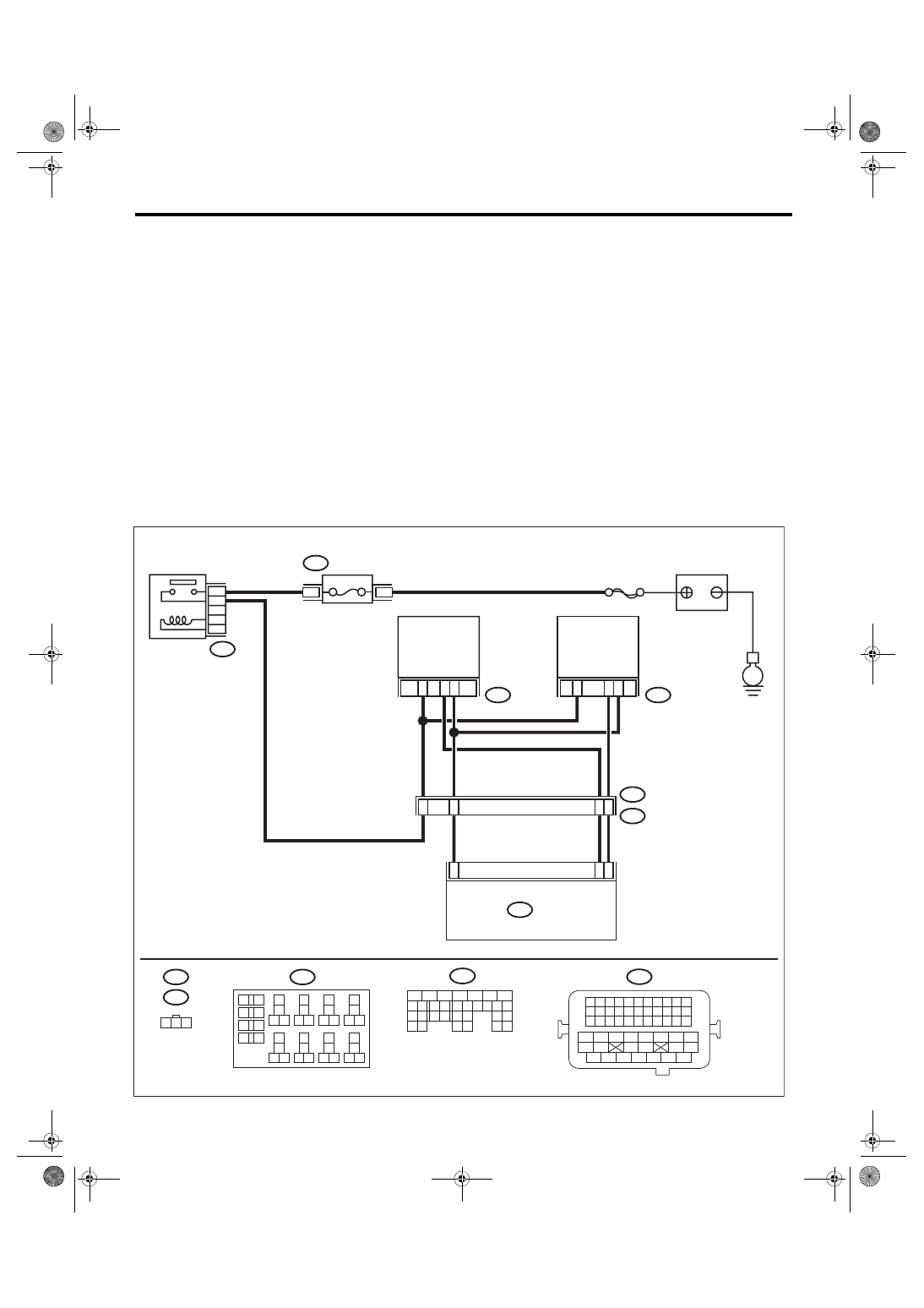

BN:DTC P0340 CAMSHAFT POSITION SENSOR “A” CIRCUIT (BANK 1 OR SIN-

GLE SENSOR)

DTC DETECTING CONDITION:

• Immediately at fault recognition

• GENERAL DESCRIPTION <Ref. to GD(H4DOTC)-132, DTC P0340 CAMSHAFT POSITION SENSOR

“A” CIRCUIT (BANK 1 OR SINGLE SENSOR), Diagnostic Trouble Code (DTC) Detecting Criteria.>

TROUBLE SYMPTOM:

• Engine stalls.

• Failure of engine to start

CAUTION:

After servicing or replacing faulty parts, perform Clear Memory Mode <Ref. to EN(H4DOTC)(diag)-63,

OPERATION, Clear Memory Mode.>, and Inspection Mode <Ref. to EN(H4DOTC)(diag)-49, PROCE-

WIRING DIAGRAM:

• Engine electrical system, without SI-DRIVE <Ref. to WI-32, WITHOUT SI-DRIVE, WIRING DIAGRAM,

• Engine electrical system, with SI-DRIVE <Ref. to WI-48, WITH SI-DRIVE, WIRING DIAGRAM, Engine

ECM

EN-08732

3

30

E35

E2

B21

2

E36

1

3

24

2

1

B137

E36

1 2 3

E35

16

B21

1 2 3 4

12 13 14 15

5 6 7 8

16 17 18 19

9 10 11

20 21 22

23 24 25 26 27 28 29 30 31 32 33

35

34

37

36

39

38

41

40

43

42

44 45

47

46

49

48

51

50

53

52

54

5

4

8

2

13

B220

24

23

22

21

B137

31

30

29

28

27

21

20

19

18

17

16

26

25

24

15

14

13

12

11

23

22

10

3

4

9

1

2

8

7

6

5

B220

18

19

6

7

4

3

5

2

1

12

11

10

9

8

40

36 39

38

37

34

33

35

32

28 31

30

29

23

22

21

20

26

25

24

27

17

16

15

14

13

4

3

B220

15A

SBF-7

E

FUSE

(RELAY BLOCK)

MAIN RELAY

INTAKE

CAMSHAFT

POSITION

SENSOR LH

INTAKE

CAMSHAFT

POSITION

SENSOR RH

BATTERY

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст