Subaru Impreza 3 / Impreza WRX / Impreza WRX STI. Service manual — part 588

AC-11

General Description

HVAC SYSTEM (HEATER, VENTILATOR AND A/C)

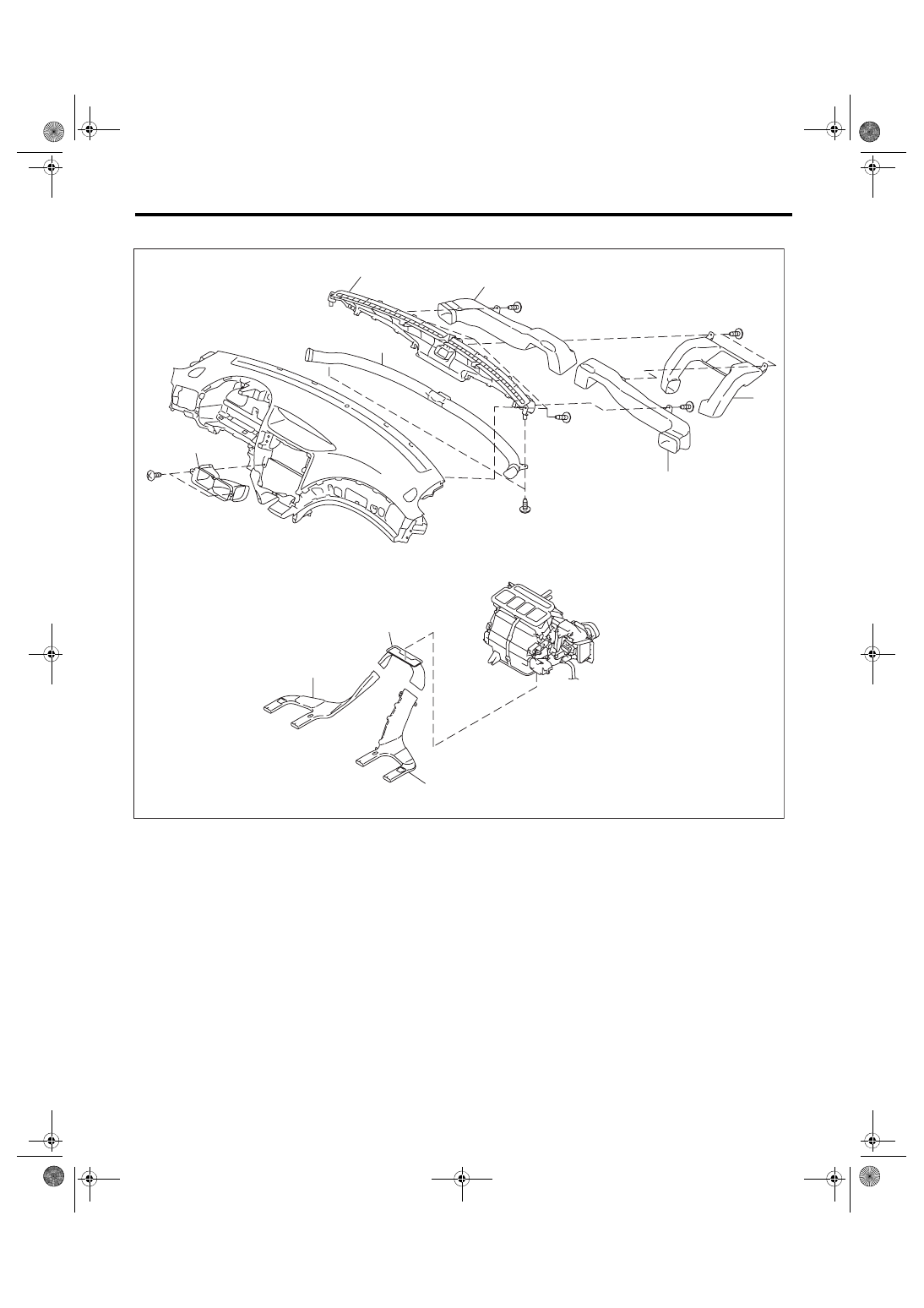

7. HEATER DUCT

(1)

Front defroster nozzle

(4)

Side vent duct (RH)

(7)

Rear heater duct (LH)

(2)

Side defroster duct

(5)

Center vent duct

(8)

Rear heater duct (RH)

(3)

Side vent duct (LH)

(6)

Center vent duct front

(9)

Rear heater duct center

(7)

(6)

(2)

(1)

(3)

(4)

(5)

(8)

(9)

AC-01969

AC-12

General Description

HVAC SYSTEM (HEATER, VENTILATOR AND A/C)

C: CAUTION

• Before disassembling or reassembling parts, al-

ways disconnect the battery ground cable from bat-

tery. When replacing the audio, control module and

other parts provided with memory functions, record

the memory contents before disconnecting the bat-

tery ground cable. Otherwise, the memory is

cleared.

• Reassemble the parts in the reverse order of dis-

assembly procedure unless otherwise indicated.

• Adjust parts to the given specifications.

• Connect the connectors securely during reas-

sembly.

• After reassembly, make sure that the functional

parts operate normally.

1. HFC-134A A/C SYSTEM

• The cooling system components for the HFC-

134a system such as the refrigerant and compres-

sor oil are different from the conventional CFC-12

system components and they are incompatible with

each other.

• Vehicles with the HFC-134a system can be iden-

tified by the label (A) attached to the vehicle.

Before maintenance, check which A/C system is in-

stalled to the vehicle.

2. COMPRESSOR OIL

• HFC-134a compressor oil has no compatibility

with that of CFC-12 system.

• Use only the manufacturer-authorized compres-

sor oil for the HFC-134a system; only use DH-PR

(ZXL200PG).

• Do not mix multiple compressor oils.

If CFC-12 compressor oil is used in the HFC-134a

A/C system, the compressor may become stuck

due to poor lubrication, or the refrigerant may leak

due to swelling of rubber parts.

On the other hand, if HFC-134a compressor oil is

used in a CFC-12 A/C system, the durability of the

A/C system will be lowered.

• HFC-134a compressor oil is very hygroscopic.

When replacing or installing/removing A/C parts,

immediately isolate the oil from atmosphere using a

plug or tape. In order to avoid moisture, store the oil

in a container with its cap tightly closed.

3. REFRIGERANT

• CFC-12 refrigerant cannot be used in a HFC-

134a A/C system. HFC-134a refrigerant, also can-

not be used in a CFC-12 A/C system.

• If an incorrect or no refrigerant is used, it will re-

sult in poor lubrication and the compressor itself

may be damaged.

4. HANDLING OF REFRIGERANT

• The refrigerant boils at approx. –30°C (–22°F).

When handling it, be sure to wear protective gog-

gles and protective gloves. Direct contact of the re-

frigerant with skin may cause frostbite.

If the refrigerant gets into your eye, avoid rubbing

your eyes with your hands. Wash your eye with

plenty of water, and receive medical treatment from

an eye doctor.

• Do not heat a service can. If a service can is di-

rectly heated, or put into boiling water, the inside

pressure will become extremely high. This may

cause the can to explode. If a service can must be

warmed up, use warm water of 40°C (104°F) or

less.

• Do not drop or impact a service can. (Observe

the precautions and operation procedure described

on the refrigerant can.)

• When the engine is running, do not open the

high-pressure valve of manifold gauge. The high-

pressure gas will back-flow resulting in an explo-

sion of the can.

• Provide good ventilation and do not work in a

closed area.

• In order to prevent global warming, avoid releas-

ing HFC-134a into the atmosphere. Using a refrig-

erant recovery system, discharge and recycle the

gas.

(A)

AC-01771

AC-13

General Description

HVAC SYSTEM (HEATER, VENTILATOR AND A/C)

5. O-RING CONNECTIONS

• Always use a new O-ring.

• In order to keep the O-rings free of lint which will

cause a refrigerant gas leak, perform work without

using gloves or waste cloths.

• Apply compressor oil to O-rings to avoid sticking,

before installation.

• Use a torque wrench to tighten the O-ring fittings.

Over-tightening will result in damage of the O-ring

and deformation of the pipe end.

• If the work is interrupted before completing pipe

connections, recap the pipes, components and fit-

tings with a plug or tape to prevent foreign matter

from entering.

• Visually check the surfaces and mating surfaces

of O-rings, threads and connecting points. If a fail-

ure is found, replace the applicable parts.

• Install the O-rings straight against the pipe

groove.

• Use compressor oil specified in the service man-

ual to lubricate the O-rings.

Apply oil to the top and sides of O-rings before in-

stallation.

Apply compressor oil to the pipe grooves.

• After tightening, use a clean cloth to remove ex-

cess compressor oil from the connections and any

oil which may have run on the vehicle body or other

parts.

• If any leakage is suspected after tightening, do

not tighten the connections further, but disconnect

the connections, remove the O-rings, and check

the O-rings, threads, and connections.

(A) Goggles

(B) Gloves

(C) Avoid open flame

(D) No direct heat on container

(E) Do not discharge

(F) Loosen

(A) Seal

(A)

(B)

(C)

(D)

(E)

(F)

AC-00007

AC-00008

(A)

(A) O-ring

(B) OK

(C) NG

(D) Groove

AC-00009

(D)

(B)

(C)

(C)

(A)

AC-00010

AC-14

General Description

HVAC SYSTEM (HEATER, VENTILATOR AND A/C)

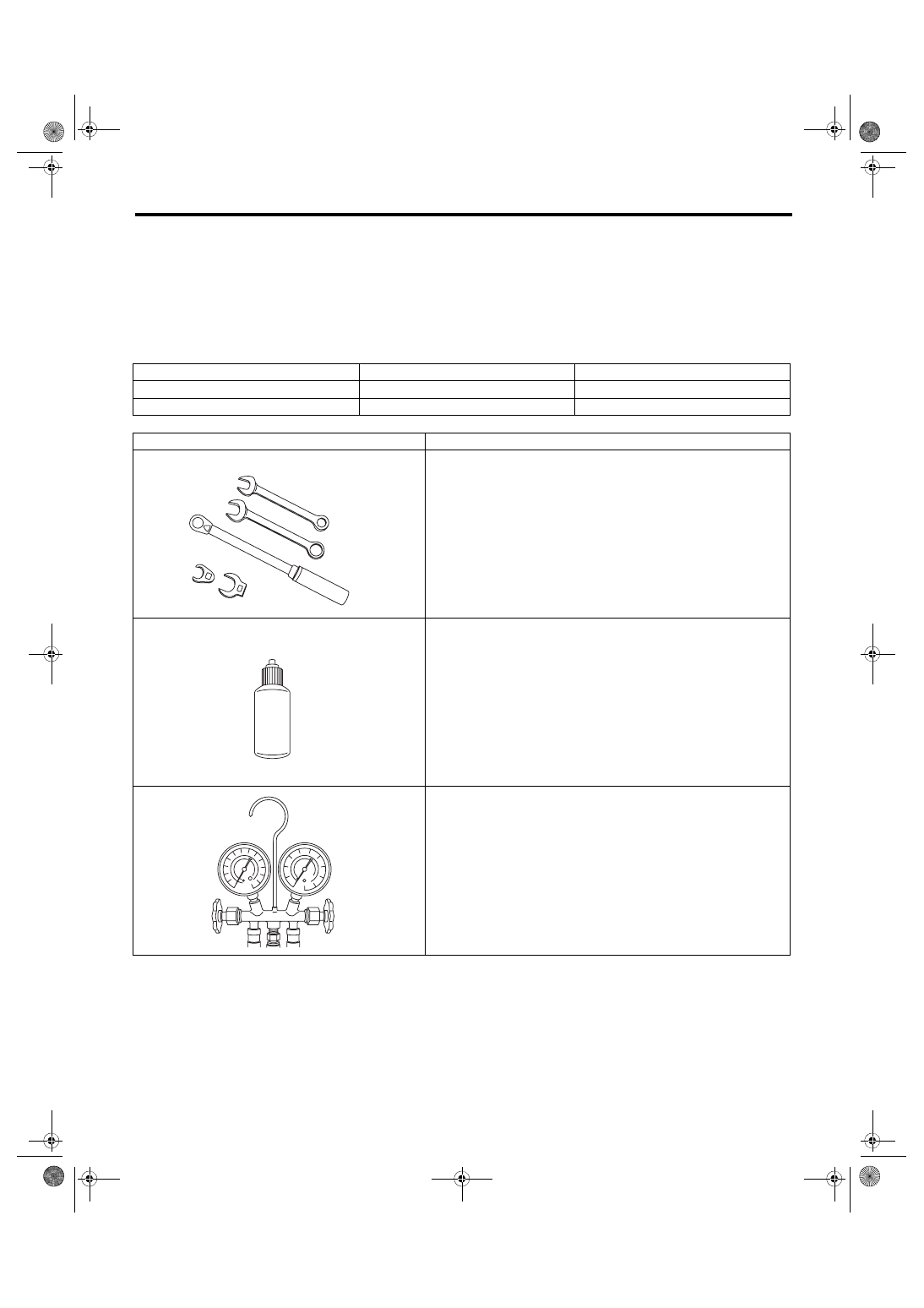

D: PREPARATION TOOL

CAUTION:

When working on vehicles with a HFC-134a system, only use HFC-134a specified tools and parts. Do

not mix CFC-12 tools and parts. If HFC-134a and CFC-12 refrigerant or compressor oil is mixed, it will

result in poor lubrication and the compressor itself may be damaged.

In order to prevent the mixture of HFC-134a and CFC-12 parts and liquid, the type of tool and screw,

and the replacement valves used are different. The gas leak detectors for the HFC-134a and CFC-12

systems must also not be interchanged.

HFC-134a

CFC-12

Tool & screw type

Millimeter size

Inch size

Valve type

Quick joint type

Screw-in type

Illustration

Tools and Equipment

Wrench

Various

WRENCHES will be required to service any A/C system. 7 —

40 N·m (0.7 to 4.1 kgf-m, 5 to 30 ft-lb) torque wrench and various crow-

foot wrenches will be needed. Open end or flare nut wrenches will be

needed to hold the tube and hose fittings.

Applicator bottle

A small

APPLICATOR BOTTLE is recommended to apply compressor

oil to the various parts. It can be available at a hardware store.

Manifold gauge set

A

MANIFOLD GAUGE SET (with hoses) is available at either a refrig-

erant supplier or an automotive equipment supplier.

AC-00213

AC-00012

AC-00013

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст