Suzuki Grand Vitara JB627. Service manual — part 404

9K-9 Body Structure:

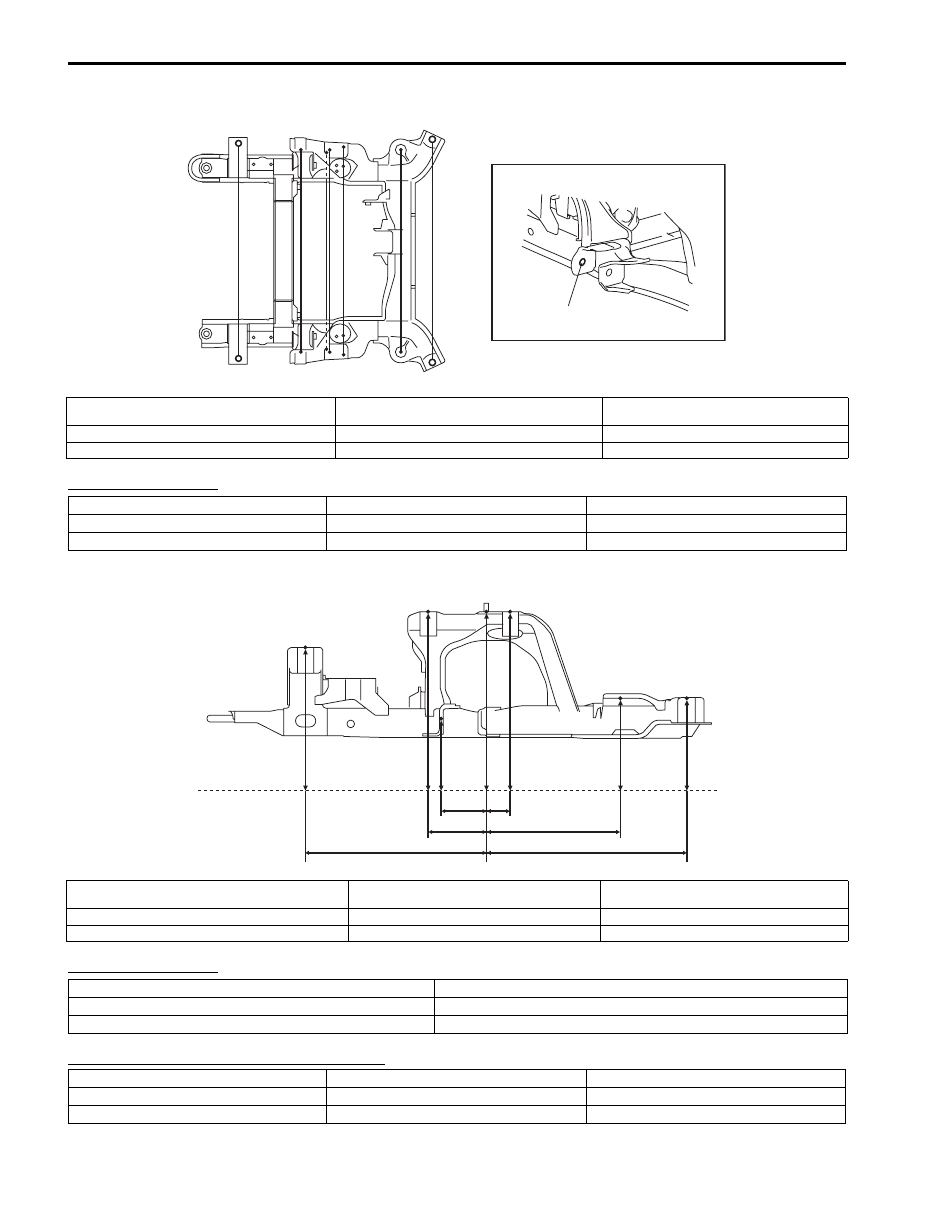

Front Suspension Frame

Hole to hole distance

Hole to hole distance

Projection dimension from standard line “A”

a

b

c

d e

f

g

a'

b'

c'

c'

d' e'

f'

g'

I5JB0A9B0013-01

a (a’). Front suspension frame installation front side

bolt hole

d (d’). Front suspension frame stud

g (g’). Front suspension frame installation rear

side bolt hole

b (b’). Front suspension frame installation bolt hole

e (e’). Front suspension frame installation bolt hole

c (c’). Front suspension arm installation front side hole

f (f’). Front suspension arm installation rear side hole

a-a’: 830 mm (32.68 in.)

d-d’: 790 mm (31.10 in.)

g-g’: 860 mm (33.86 in.)

b-b’: 840 mm (33.07 in.)

e-e’: 794 mm (31.26 in.)

c-c’: 780 mm (30.71 in.)

f-f’: 780 mm (30.71 in.)

a

b

c

d

e

f

g

“A”

I5JB0A9B0014-01

a. Front suspension frame installation front side bolt hole

d. Front suspension frame stud

g. Front suspension frame installation rear side

bolt hole

b. Front suspension frame installation bolt hole

e. Front suspension frame installation bolt hole

c. Front suspension arm installation front side hole

f. Front suspension arm installation rear side hole

a-d: 349 mm (13.74 in.)

d-e: 51 mm (2.01 in.)

b-d: 110 mm (4.33 in.)

d-f: 275 mm (10.83 in.)

c-d: 80 mm (3.15 in.)

d-g: 395 mm (15.55 in.)

a: 193 mm (7.60 in.)

d: 263 mm (10.35 in.)

g: 95 mm (3.74 in.)

b: 263 mm (10.35 in.)

e: 263 mm (10.35 in.)

c: 49 mm (1.93 in.)

f: 96 mm (3.78 in.)

Body Structure: 9K-10

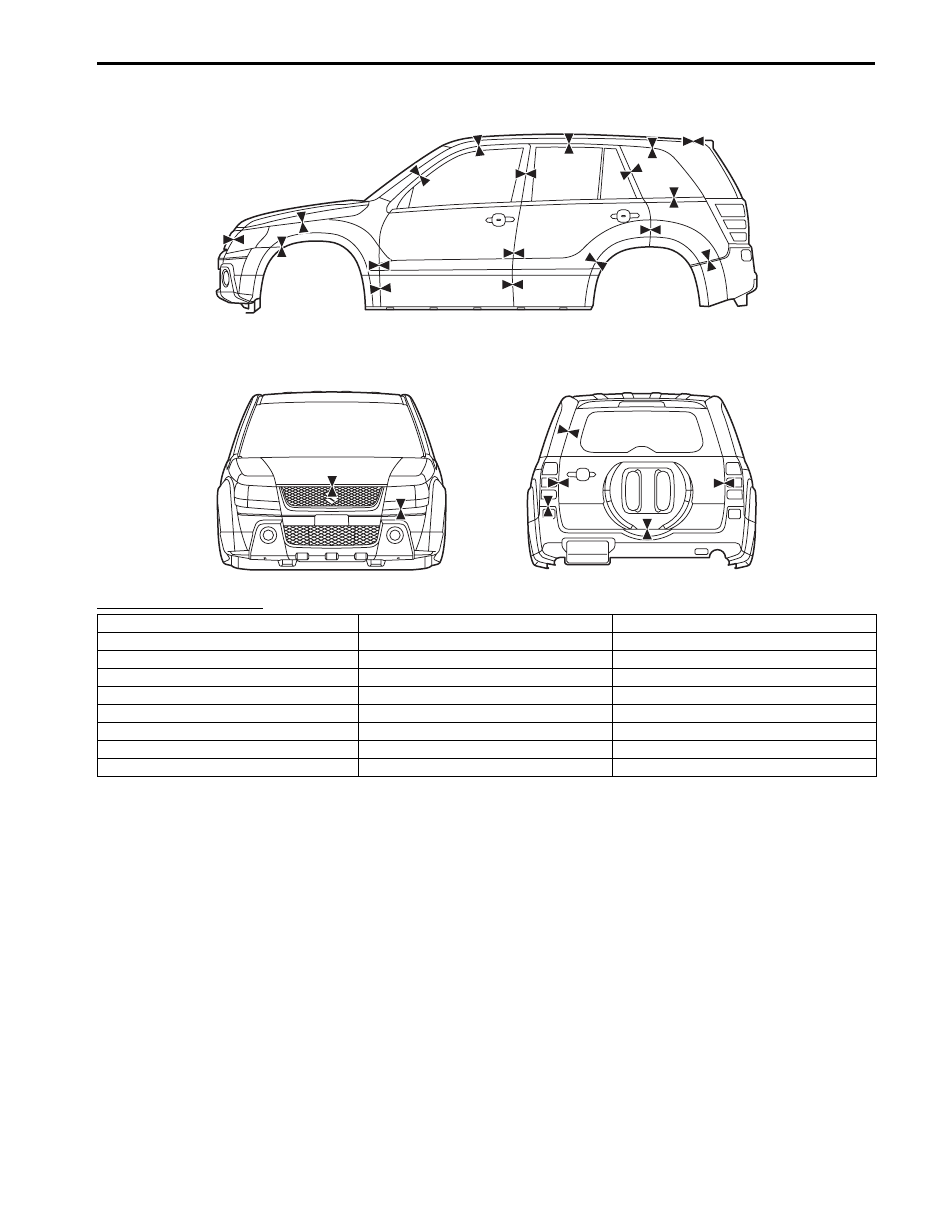

Panel Clearance

S6JB0B9B07002

Panel to panel distance

b

c

f

a

e

d

g

i

j

q

l

m

r

n

o

h

s

p

aa

bb

cc

ee

ff

k

dd

I6JB019B0004-01

a: 7.5 – 9.5 mm (0.296 – 0.374 in.)

j: 4.0 – 6.0 mm (0.158 – 0.236 in.)

s: 16.8 – 18.8 mm (0.662 – 0.740 in.)

b: 1.0 – 3.0 mm (0.040 – 0.118 in.)

k: 3.0 – 5.0 mm (0.119 – 0.196 in.) aa: 4.0 – 6.0 mm (0.158 – 0.236 in.)

c: 1.9 – 3.9 mm (0.075 – 0.153 in.)

l: 3.0 – 5.0 mm (0.119 – 0.196 in.) bb: 6.3 – 8.3 mm (0.249 – 0.327 in.)

d: 0.5 – 1.0 mm (0.020 – 0.039 in.)

m: 4.0 – 6.0 mm (0.158 – 0.236 in.) cc: 5.0 – 7.0 mm (0.197 – 0.275 in.)

e: 7.0 – 9.0 mm (0.275 – 0.354 in.)

n: 3.3 – 5.3 mm (0.120 – 0.208 in.) dd: 6.2 – 8.2 mm (0.245 – 0.322 in.)

f: 3.0 – 5.0 mm (0.119 – 0.196 in.)

o: 1.8 – 3.8 mm (0.071 – 0.149 in.) ee: 4.0 – 6.0 mm (0.158 – 0.236 in.)

g: 4.0 – 6.0 mm (0.158 – 0.236 in.)

p: 0.5 – 1.0 mm (0.020 – 0.039 in.)

ff: 1.0 – 3.0 mm (0.040 – 0.118 in.)

h: 6.0 – 8.0 mm (0.237 – 0.314 in.)

q: 3.0 – 5.0 mm (0.119 – 0.196 in.)

i: 4.0 – 6.0 mm (0.158 – 0.236 in.)

r: 4.0 – 6.0 mm (0.158 – 0.236 in.)

9L-1 Paint / Coatings:

Body, Cab and Accessories

Paint / Coatings

General Description

Anti-Corrosion Treatment Construction

S6JB0B9C01001

WARNING

!

Standard shop practices, particularly eye

protection, should be followed during the

performance of the following operations to

avoid personal injury.

As rust proof treatment, steel sheets are given corrosion

resistance on the interior and/or exterior.

These corrosion resistance steel sheet materials are

called one of two-side galvanized steel sheets.

It is for the sake of rust protection that these materials

are selected and given a variety of treatments as

described blow.

• Steel sheets are treated with cathodic electro primer

which is excellent in corrosion resistance.

• Rust proof wax coatings are applied to door and side

sill insides where moisture is liable to stay.

• Vinyl coating is applied to body underside and wheel

housing inside.

• Sealer is applied to door hem, engine compartment

steel sheet-to-steel sheet joint, and the like portions to

prevent water penetration and resulting in rust

occurrence.

In panel replacement or collision damage repair, leaving

the relevant area untreated as it is in any operation

which does disturb the rust proof treatment will cause

corrosion to that area. Therefore, it is the essential

function of any repair operation to correctly recoat the

related surfaces of the relevant area.

All the metal panels are coated with metal conditioners

and primer coating during vehicle production. Following

the repair and/or replacement parts installation, every

accessible bare metal surface should be cleaned and

coated with rust proof primer. Perform this operation

prior to the application of sealer and rust proof wax

coating.

Sealer is applied to the specific joints of a vehicle during

production. The sealer is intended to prevent dust from

entering the vehicle and serves also as an anticorrosion

barrier. The sealer is applied to the door and hood hem

areas and between panels. Correct and reseal the

originally sealed joints if damaged. Reseal the attaching

joints of a new replacement panel and reseal the hem

area of a replacement door or hood.

Use a quality sealer to seal the flanged joints, overlap

joints and seams. The sealer must have flexible

characteristics and paint ability after it’s applied to repair

areas.

For the sealer to fill open joints, use caulking material.

Select a sealer in conformance with the place and

purpose of a specific use. Observe the manufacturer’s

label-stand instructions when using the sealer.

In many cases, repaired places require color painting.

When this is required, follow the ordinary techniques

specified for the finish preparation, color painting and

undercoating build-up.

Rust proof wax, a penetrative compound, is applied to

the metal-to-metal surfaces (door and side sill insides)

where it is difficult to use ordinary undercoating material

for coating. Therefore, when selecting the rust proof

wax, it may be the penetrative type.

During the undercoating (vinyl coating) application, care

should be taken that sealer is not applied to the engine-

related parts and shock absorber mounting or rotating

parts. Following the under coating, make sure that body

drain holes are kept open.

The sequence of the application steps of the anti-

corrosion materials are as follows:

1) Clean and prepare the metal surface.

2) Apply primer.

3) Apply sealer (all joints sealed originally).

4) Apply color in areas where color is required such as

hem flanges, exposed joints and under body

components.

5) Apply anticorrosion compound (penetrative wax).

6) Apply undercoating (rust proof material).

Paint / Coatings: 9L-2

Plastic Parts Finishing

S6JB0B9C01002

Paintable plastic parts are ABS plastic parts.

Painting

Rigid or hand ABS plastic needs no primer coating.

General acrylic lacquers can be painted properly over

hard ABS plastic in terms of adherence.

1) Use cleaning solvent for paint finish to wash each

part.

2) Apply conventional acrylic color lacquer to part

surface.

3) Follow lacquer directions for required drying time.

(Proper drying temperature range is 60 – 70

°C (140

– 158

°F)).

Reference

Plastic parts employ not only ABS (Acrylonitrile

Butadiene Styrene) plastic but also polypropylene, vinyl,

or the like plastic. Burning test method to identify ABS

plastic is described below.

1) Use a sharp blade to cut off a plastic sliver from the

part at its hidden backside.

2) Hold sliver with pincers and set it on fire.

3) Carefully observe condition of the burning plastic.

4) ABS plastic must raise readily distinguishable back

smoke while burning with its residue suspended in

air temporarily.

5) Polypropylene must raise no readily distinguishable

smoke while burning.

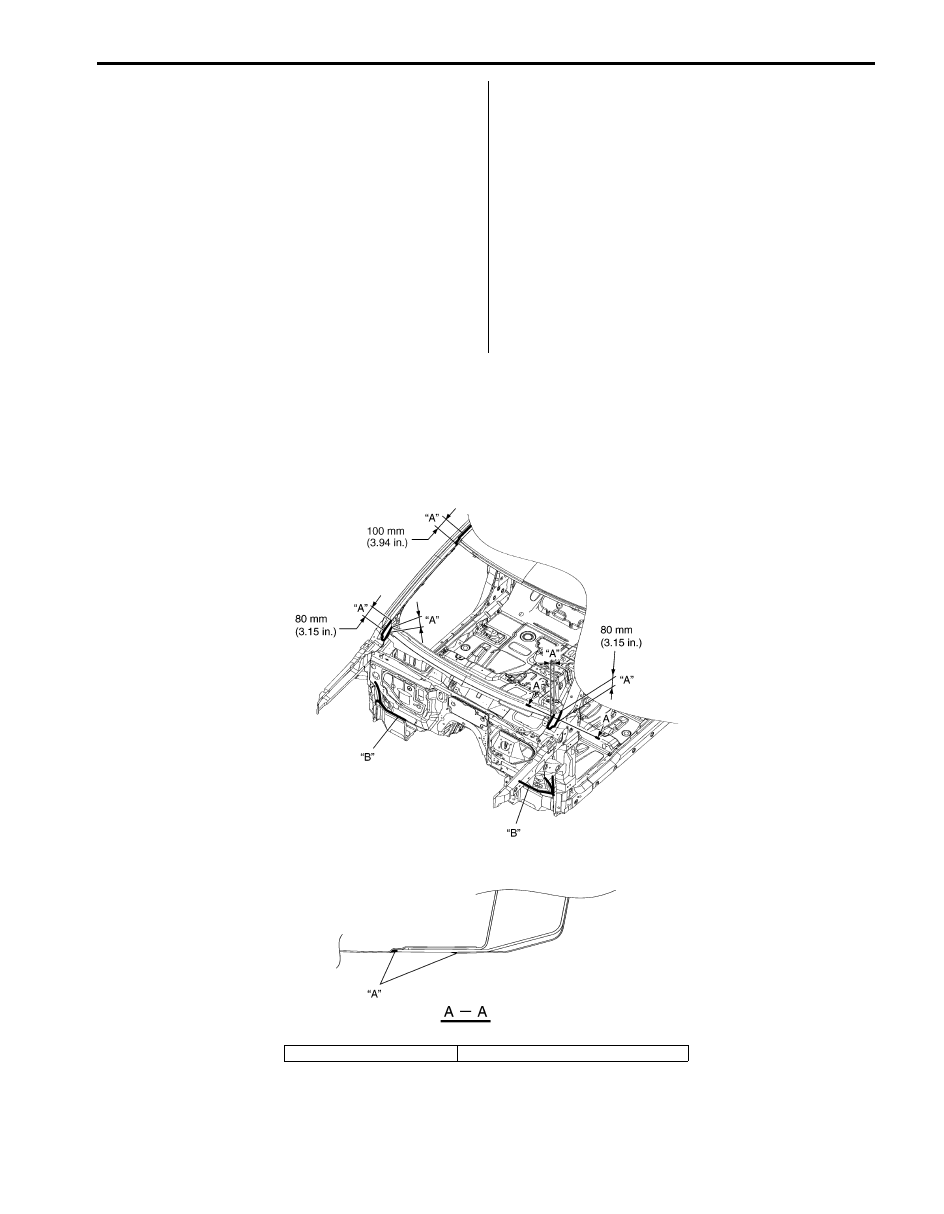

Component Location

Sealant Application Areas

S6JB0B9C03001

Front Structure Panel

I5JB0A9C0001-03

“A”: Flatten sealant.

“B”: Smooth out sealant with a brush.

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст