Suzuki Grand Vitara JB627. Service manual — part 190

4E-41 ABS:

Rear Wheel Speed Sensor Inspection

S6JB0B4506010

Refer to “Front Wheel Speed Sensor Inspection” since

rear wheel speed sensor is the same as front wheel

speed sensor.

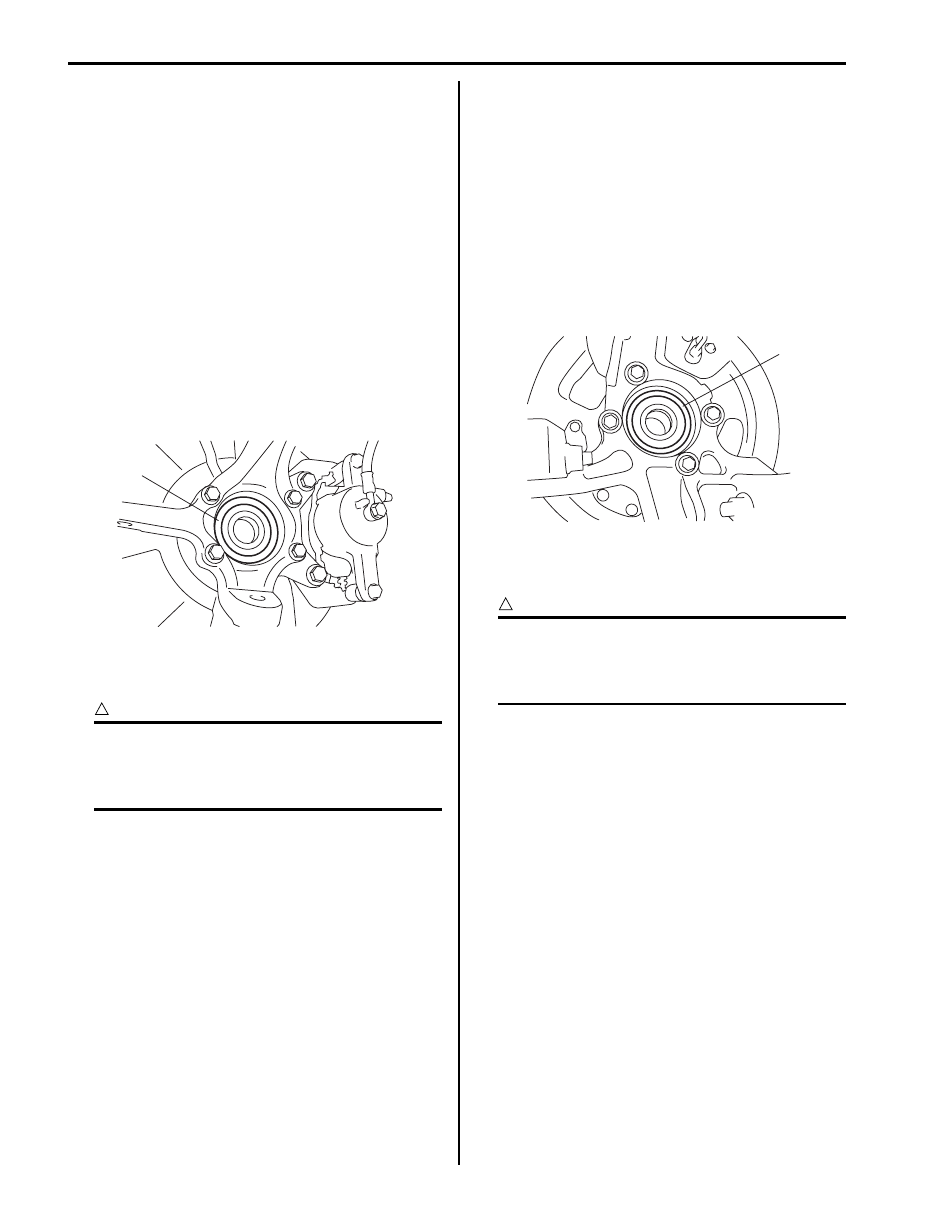

Front Wheel Encoder On-Vehicle Inspection

S6JB0B4506011

Before inspect front wheel encoder, remove front drive

shaft referring to “Front Drive Shaft Assembly Removal

and Installation: Front in Section 3A”.

• Check encoder (1) for being crack, damaged or

deformed.

• Turn wheel and check if encoder rotation is free from

eccentricity and looseness.

• Check that no foreign material is attached.

If any faulty is found, repair or replace. Refer to “Front

Wheel Hub Assembly Removal and Installation in

Section 2B”.

Front Wheel Encoder Removal and Installation

S6JB0B4506012

CAUTION

!

Front wheel encoder is included in front

wheel hub assembly. If front wheel encoder

needs to replaced, replace it as a front wheel

hub assembly.

For removal and installation of front wheel hub

assembly, referring to “Front Wheel Hub Assembly

Removal and Installation in Section 2B”.

Rear Wheel Encoder On-Vehicle Inspection

S6JB0B4506013

Before inspect rear wheel encoder, remove rear drive

shaft referring to “Rear Drive Shaft Assembly Removal

and Installation: Rear in Section 3A”.

• Check encoder (1) for being crack, damaged or

deformed.

• Turn wheel and check if encoder rotation is free from

eccentricity and looseness.

• Check that no foreign material is attached.

If any faulty is found, repair or replace. Refer to “Rear

Wheel Hub Assembly Removal and Installation in

Section 2C”.

Rear Wheel Encoder Removal and Installation

S6JB0B4506014

CAUTION

!

Rear wheel encoder is included in rear wheel

hub assembly. If rear wheel encoder needs to

replaced, replace it as a rear wheel hub

assembly.

For removal and installation of front wheel hub

assembly, referring to “Rear Wheel Hub Assembly

Removal and Installation in Section 2C”.

1

I5JB0A450034-01

1

I5JB0A450035-01

ABS: 4E-42

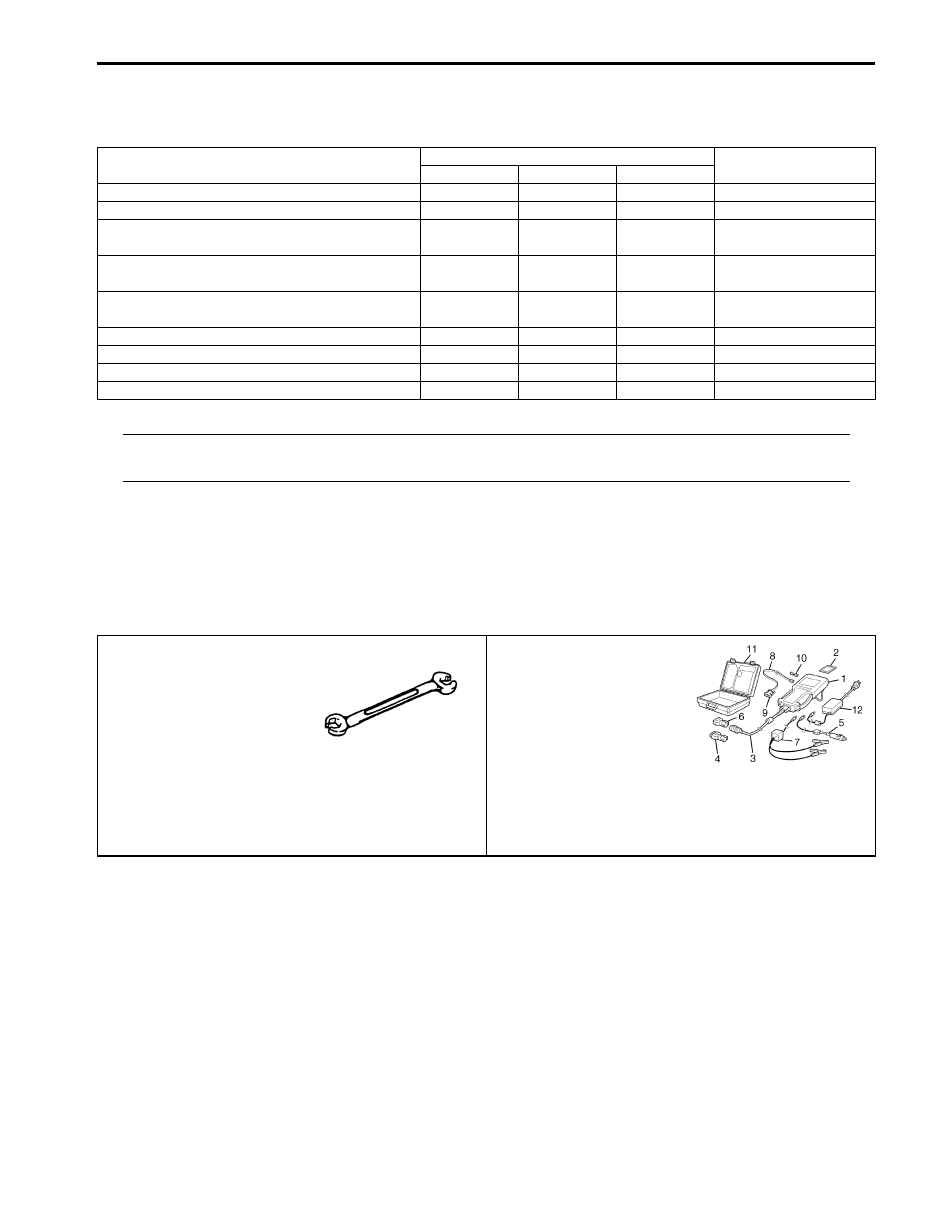

Specifications

Tightening Torque Specifications

S6JB0B4507001

NOTE

The specified tightening torque is also described in the following.

“ABS (ESP

®) hydraulic unit / control module Assembly Components”

Reference:

For the tightening torque of fastener not specified in this section, refer to “Fastener Information in Section 0A”.

Special Tools and Equipment

Special Tool

S6JB0B4508001

Fastening part

Tightening torque

Note

N

⋅m

kgf-m

lb-ft

Brake pipe flare nut (M10)

16

1.6

11.5

Brake pipe flare nut (M12)

19

1.9

14.0

ABS (ESP

®) hydraulic unit / control module

assembly bolt

9

0.9

6.5

ABS (ESP

®) hydraulic unit / control module

assembly bracket bolt

25

2.5 18.0

ABS (ESP

®) hydraulic unit / control module

assembly bracket nut

25

2.5 18.0

Front wheel speed sensor bolt

11

1.1

8.0

Front wheel speed sensor harness clamp bolt

11

1.1

8.0

Rear wheel speed sensor bolt

11

1.1

8.0

Rear wheel speed sensor harness clamp bolt

11

1.1

8.0

09950–78220

SUZUKI scan tool

Flare nut wrench (10 mm)

—

This kit includes following

items. 1. Tech 2, 2. PCMCIA

card, 3. DLC cable, 4. SAE

16/19 adapter, 5. Cigarette

cable, 6. DLC loop back

adapter, 7. Battery power

cable, 8. RS232 cable, 9.

RS232 adapter, 10. RS232

loop back connector, 11.

Storage case, 12. ) / )

4F-1 Electronic Stability Program:

Brakes

Electronic Stability Program

Precautions

Precautions in Diagnosing Troubles

S6JB0B4600001

To ensure that the trouble diagnosis is done accurately

and smoothly, observe the following and follow

“Electronic Stability Program Check”.

• Diagnostic information stored in ESP

® control module

memory can be cleared as well as checked by using

SUZUKI scan tool. Before using scan tool, read its

Operator’s (Instruction) Manual carefully to have good

understanding as to what functions are available and

how to use it.

• If the vehicles was operated in any of the following

ways, ESP

® warning light may light momentarily but

this does not indicate anything abnormal in ESP

®.

– The vehicle was driven with parking brake pulled.

– The vehicle was driven with brake dragging.

– The vehicle was stuck in mud, sand, etc.

– Wheel spin occurred while driving.

– Wheel(s) was rotated while the vehicle was jacked

up.

• Be sure to read “Precaution for CAN Communication

System in Section 00” before inspection and observe

what is written there.

• Be sure to use the trouble diagnosis procedure as

described in “Electronic Stability Program Check”.

Failure to follow it may result in incorrect diagnosis.

(Some other diagnosis trouble code may be stored by

mistake in the memory of ESP

® control module

during inspection.)

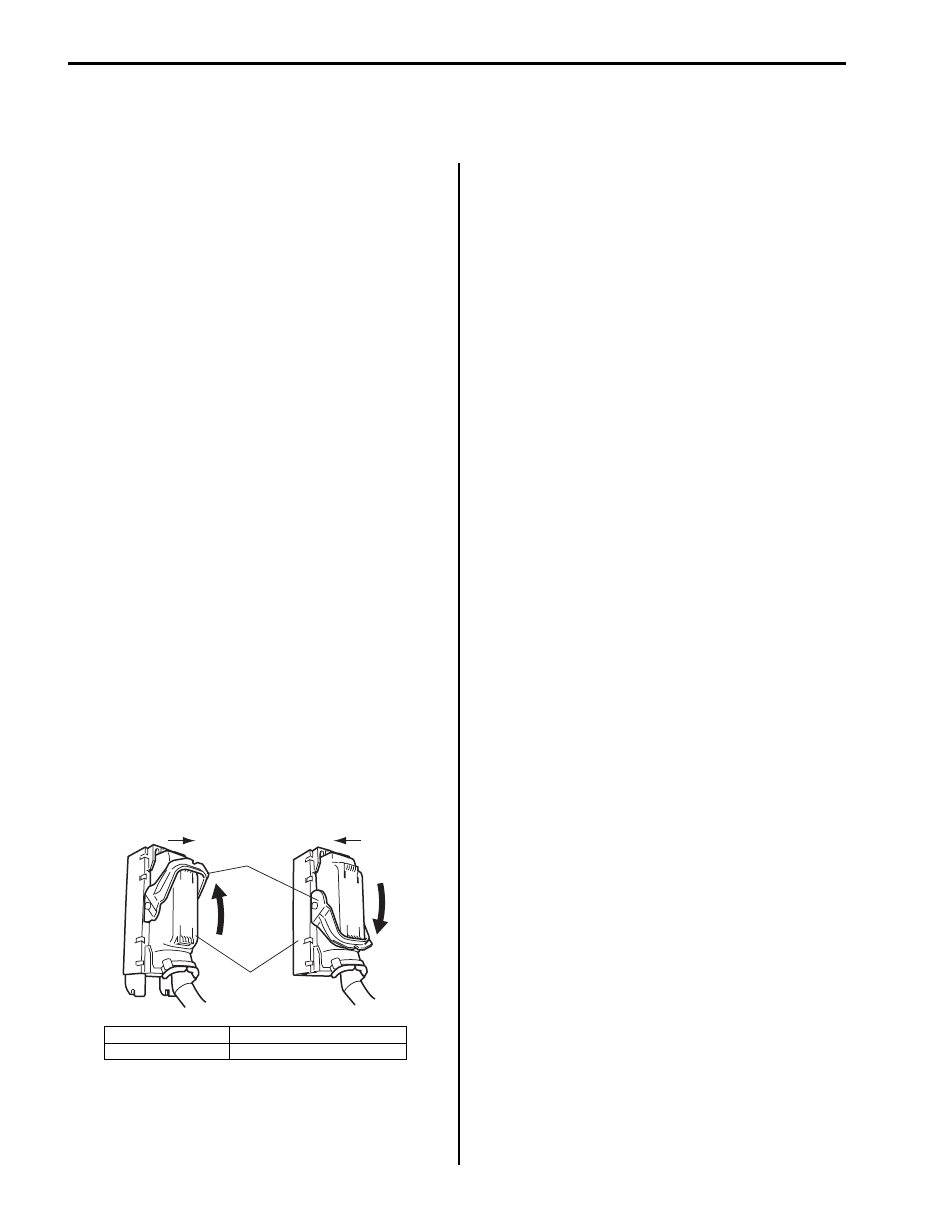

• When disconnecting ESP

® control module connector

(1), pull up lock lever (2) of connector.

When connecting, set the connector on ESP

®

hydraulic unit / control module assembly and pull

down the lock lever (2) until it locks.

• Communication of ECM, TCM (A/T model), BCM,

ESP

® (ABS) control module (if equipped), 4WD

control module (if equipped), keyless start control

module (if equipped) and combination meter is

established by CAN (Controller Area Network).

Therefore, be sure to read “Precaution for CAN

Communication System in Section 00” before

inspection and handling CAN communication line.

Precautions in On-Vehicle Service

S6JB0B4600002

When connector is connected to ESP

® hydraulic unit /

control module assembly, do not disconnect connectors

of sensors with ignition switch ON. Otherwise, DTC will

be set in ESP

® control module.

Precautions in Hydraulic Unit Operation Check

S6JB0B4600003

ESP

® hydraulic unit / control module assembly function

is checked by correct wheel lock / release condition

when brake pressure is pressurized / depressurized

using SUZUKI scan tool. The hydraulic unit operation

check referring to “Hydraulic Unit Operation Check in

Section 4E” should be performed to confirm the correct

brake pipe connection in the following cases.

• ESP

® hydraulic unit / control module assembly was

replaced.

• Brake pipe and/or hose were replaced.

[A]: Disconnect

C: Pull up to disconnect

[B]: Connect

D: Pull down to connect

2

1

[A]

[B]

C

D

I6JB01460001-01

Electronic Stability Program: 4F-2

Precautions in Sensor Calibration

S6JB0B4600004

ESP

® control module stores calibration points data of yaw rate / G sensor assembly and master cylinder pressure

sensor. Steering angle sensor stores calibration point data of itself.

TCS and stability control system use these sets of data.

When the following operation is done, calibration should be performed since the original calibration points are deleted.

Perform sensor calibration according to “Sensor Calibration”.

Precautions in Speedometer Test or Other Tests

S6JB0B4600005

When performing speedometer or a bench test while rotating a tire, ESP

® function must be kept at stop. It is possible

to stop ESP

® function temporarily by ESP® OFF switch. In this case, however, the function is forced to come back to

work when the speed exceeds 30km/h (18.5 mph) and may hinder accurate testing.

There are two ways to stop the ESP

® function completely as described bellow.

• Connect the SUZUKI scan tool, set to the “MISC. TEST” mode to stop the ESP

® function. Refer to SUZUKI scan

tool operator’s manual for further details.

• Disconnect the connector of the steering angle sensor, and ESP

® function is forced to enter the fail-safe mode,

then ESP

® function is stopped.

However, when this method is used, DTC remains in the memory of the ESP

® control module. Therefore, after the

test, re-connect the connector, clear DTC in the memory of the ESP

® control module. And calibrate steering angle

sensor referring to “Sensor Calibration”.

General Description

Electronic Stability Program Description

S6JB0B4601001

Electronic Stability Program (ESP

®) main function is to control ABS / EBD, TCS and stability.

• ABS / EBD

ABS function is that four wheel brake forces are independently varied with referring each wheel slip condition.

EBD function is that front and rear wheel braking forces are varied with referring loading distribution of the vehicle.

ABS improves the vehicle stability, controllability and braking performance.

For the details, refer to “ABS Description in Section 4E”.

• TCS (Traction Control System)

TCS function is that engine torque is controlled and brake is applied with referring wheel spin condition during

vehicle starting and accelerating.

• Stability control system

Stability control system is that engine torque is controlled and brake is applied with referring vehicle condition (over

steering, under steering) during cornering.

ESP

® is a registered trademark of Daimler Chrysler AG.

Sensor

Procedures required calibration

Steering angle sensor

• Power is not supplied to steering angle sensor. (battery and/or fuse is removed.)

• Steering angle sensor is replaced.

• Power is not supplied to ESP

® control module. (battery, fuse and/or connector is

removed.)

• ESP

® hydraulic unit / control module assembly is replaced.

Master cylinder pressure sensor • ESP

® hydraulic unit / control module assembly is removed or replaced.

Yaw rate / G sensor assembly

• Yaw rate / G sensor assembly is removed or replaced.

• ESP

® hydraulic unit / control module assembly is replaced.

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст