Opel Frontera UBS. Service manual — part 2561

AUTOMATIC TRANSMISSION (AW30-40LE)

7A–107

DISASSEMBLY, INSPECTION AND

REASSEMBLY OF MINOR COMPONENTS

The instructions here are organized so that you work on only

one component group at a time.

This will help avoid confusion from similar-looking parts of

different subassemblies being on your workbench at the same

time.

The component groups are inspected and repaired from the

converter housing side.

As much as possible, complete the inspection, repair and

reassembly before proceeding to the next component group. If

a component group cannot be reassembled because parts are

being ordered, be sure to keep all parts of that group in a

separate container while proceeding with disassembly,

inspection, repair and reassembly of other component groups.

Recommended ATF type BESCO ATF II or III.

GENERAL CLEANING NOTES:

1. All disassembled parts should be washed clean and any

fluid passages and holes blown through with compressed

air.

2. When using compressed air to dry parts, always aim away

from yourself to prevent accidentally spraying automatic

transmission fluid in your face.

3. The recommended automatic transmission fluid should be

used for cleaning.

PARTS ARRANGEMENT:

1. After cleaning, the parts should be arranged in proper order

to allow performing inspection, repairs, and reassembly

with efficiency.

2. When disassembling a valve body, be sure to keep each

valve together with the corresponding spring.

3. New brakes and clutches that are to be used for

replacement must be soaked in transmission fluid for at

least thirty before assembly.

GENERAL ASSEMBLY:

1. All oil seal rings, clutch discs, clutch plates, rotating parts,

and sliding surfaces should be coated with transmission

fluid prior to reassembly.

2. All gaskets and rubber O-rings should be replaced.

3. Make sure that ends of a snap ring are not aligned with one

of the cutouts and are installed in the groove correctly.

4. If a worn bushing is to be replaced, the subassembly

containing that bushing must be replaced.

5. Check thrust bearings and races for wear or damage.

Replace if necessary.

6. Use petroleum jelly or vaseline to keep parts in place.

7A–108

AUTOMATIC TRANSMISSION (AW30-40LE)

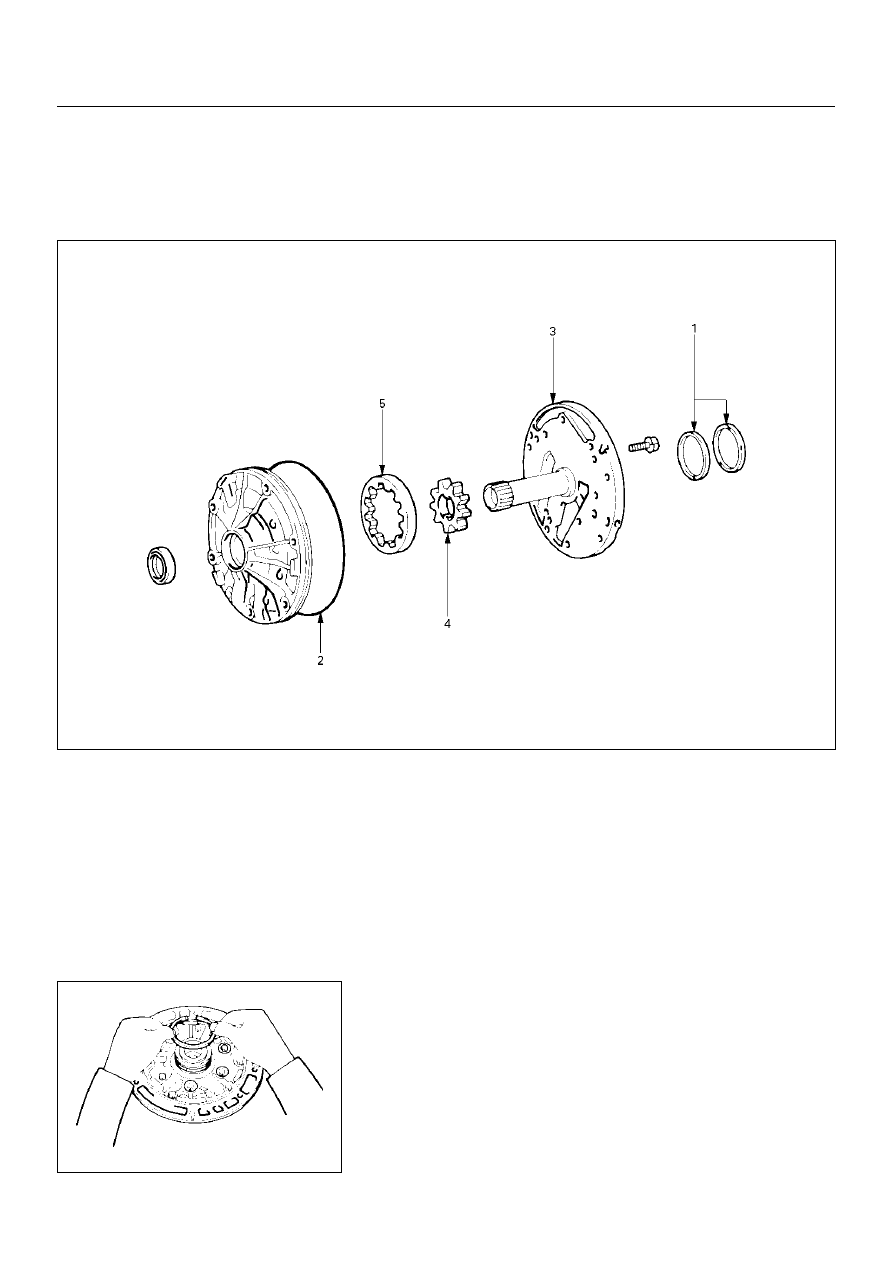

OIL PUMP

DISASSEMBLY

241RY00004

241RY00005

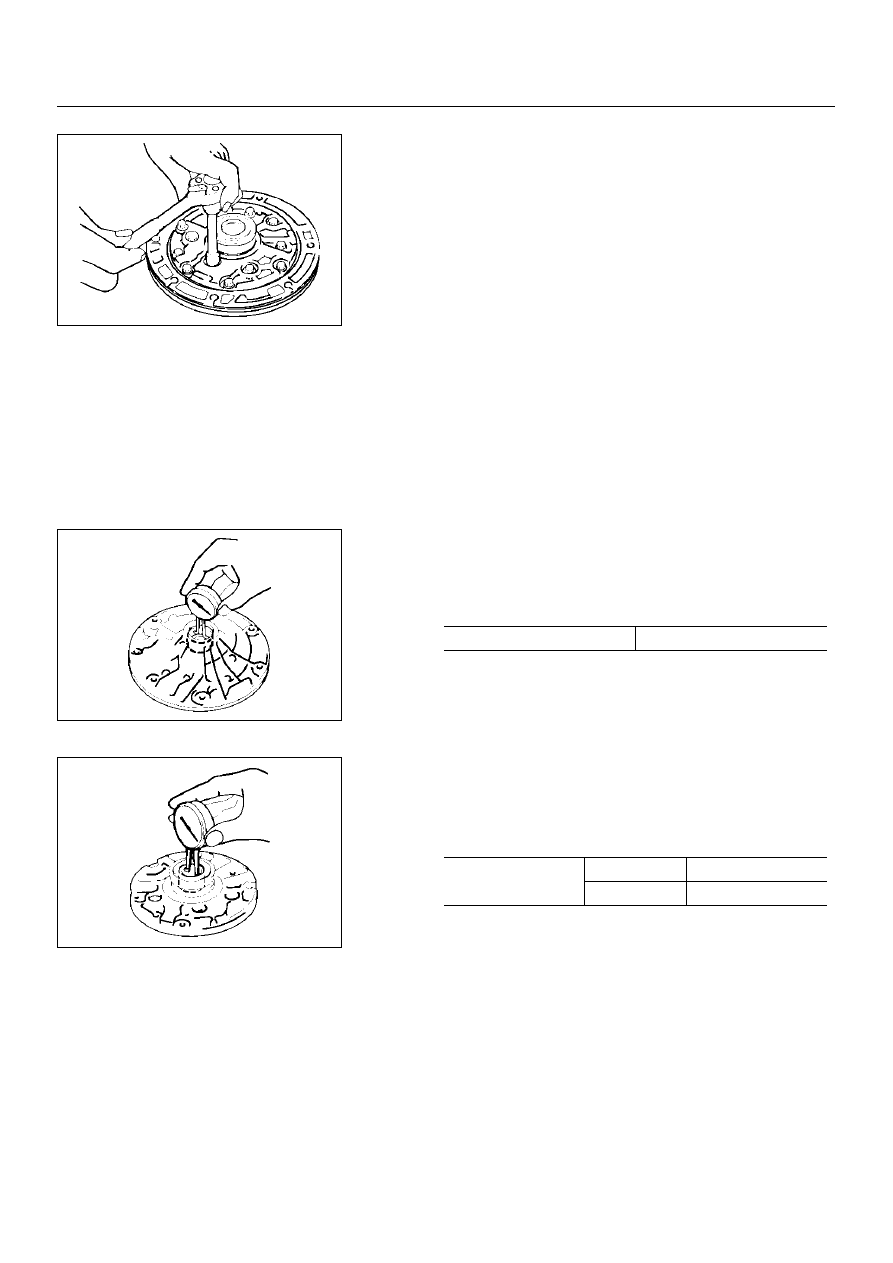

Important operations

1. Oil seal ring

Use torque converter as work stand.

Remove 2 oil seal rings from stator shaft.

2. O-ring

Remove O-ring.

Disassembly steps

▲

1. Oil seal ring

▲

2. O-ring

▲

3. Stator shaft

4. Oil pump drive gear

5. Oil pump driven gear

AUTOMATIC TRANSMISSION (AW30-40LE)

7A–109

241RY00006

241RY00007

241RY00008

3. Stator shaft

Remove 13 bolts, and then remove the stator shaft from oil

pump body.

Then remove drive and driven gear.

INSPECTION AND REPAIR

Make necessary correction or parts replacement if wear,

damage or any abnormal conditions are found through

inspection.

Check oil pump body bushing

Using a dial indicator, measure the inside diameter of the

oil pump body bushing.

If the inside diameter is greater than the maximum, replace

the oil pump body.

Check stator shaft bushing

Using a dial indicator, measure the inside diameter of the stator

shaft bushing.

If the inside diameter is greater than maximum, replace the

stator shaft.

mm (in.)

Maximum inside diameter

38.19 (1.5035)

mm (in.)

Maximum inside

diameter

Front side

21.58 (0.8496)

Rear side

27.08 (1.0661)

7A–110

AUTOMATIC TRANSMISSION (AW30-40LE)

241RY00009

241RY00010

241RY00011

241RY00012

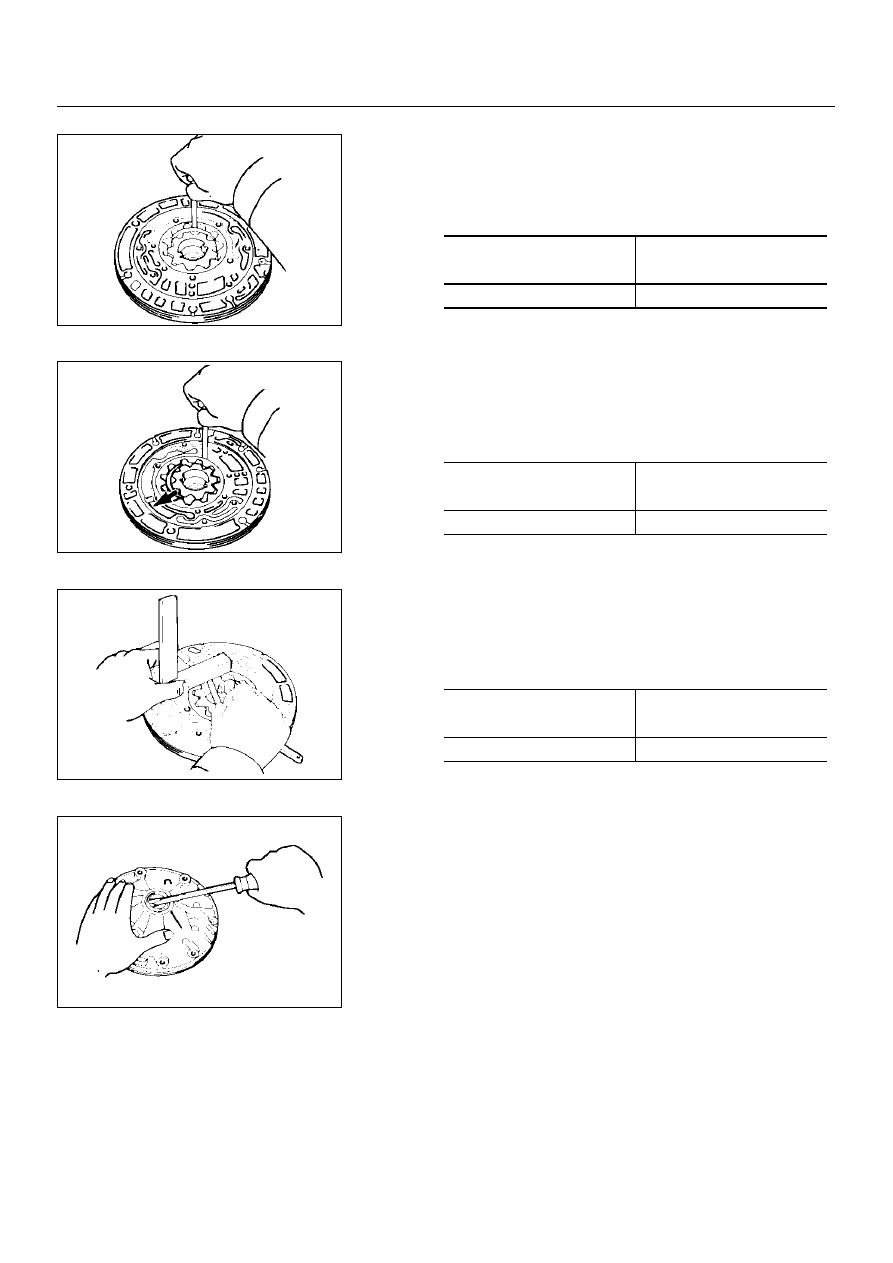

Check tip clearance of both gears

Measure between the gear teeth and the cresent-shaped

part of the pump body.

If the tip clearance is greater than the maximum, replace

the drive gear, driven gear or pump body.

Check body clearance of driven gear

Push the driven gear to one side of the body.

Use a feeler gauge, measure the clearance.

If the body clearance is greater than the maximum, replace

the drive gear, driven gear or pump body.

Check side clearance of both gears

Using a steel straightedge and a feeler gauge, measure the

side clearance of both gears.

If the side clearance is greater than the maximum, replace

the drive gear, driven gear or pump body.

Check oil seal

Check for wear, damage or cracks.

If necessary, replace oil seal.

Pry off the oil seal with a screwdriver.

mm (in.)

Standard tip clearance

0.11–0.14

(0.0043–0.0055)

Maximum tip clearance

0.3 (0.012)

mm (in.)

Standard body clearance

0.07–0.15

(0.0028–0.0059)

Maximum body clearance

0.3 (0.012)

mm (in.)

Standard side clearance

0.02–0.05

(0.0008–0.0020)

Maximum side clearance

0.1 (0.004)

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст